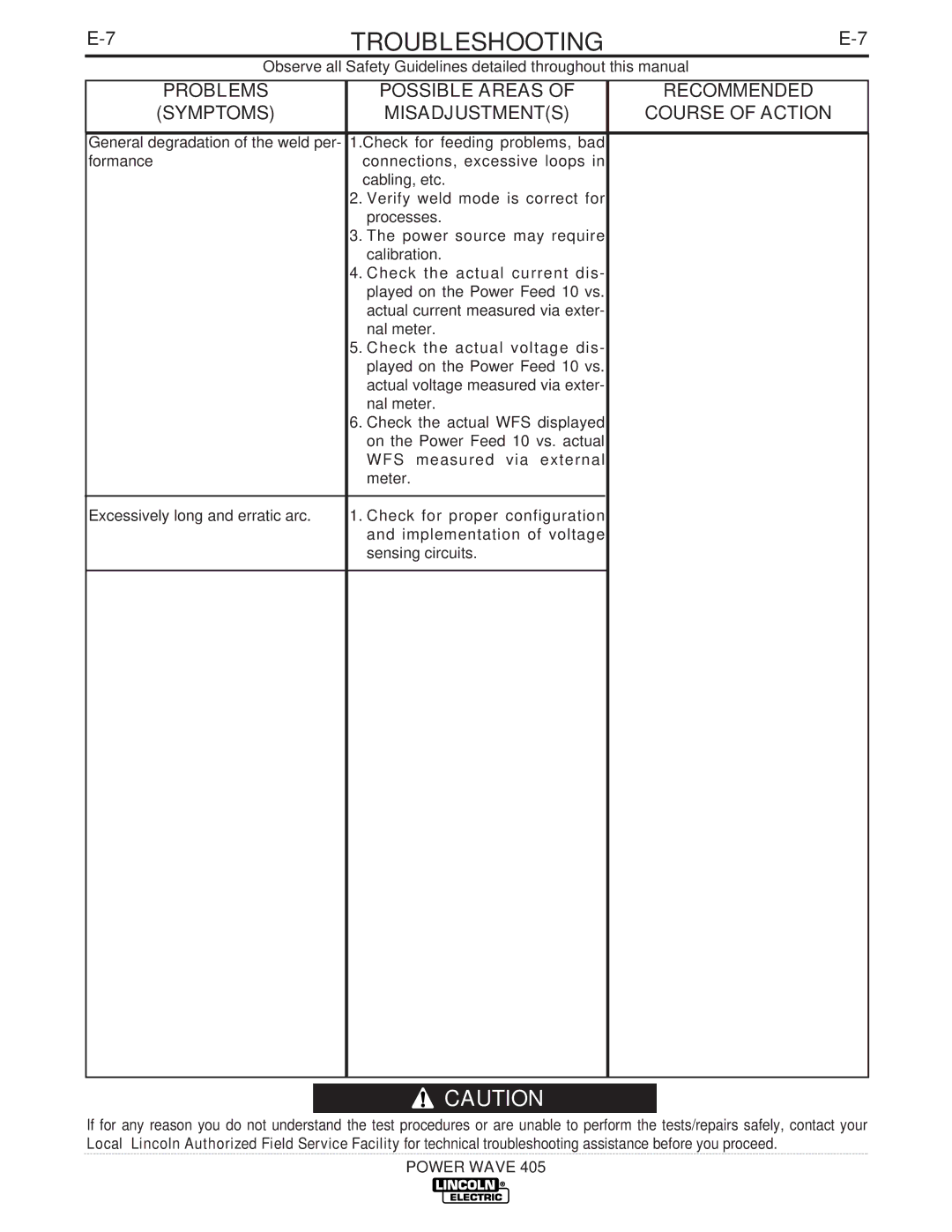

TROUBLESHOOTING | ||

|

|

|

| Observe all Safety Guidelines detailed throughout this manual |

|

|

|

|

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

General degradation of the weld per- | 1.Check for feeding problems, bad |

| |

formance |

| connections, excessive loops in |

|

|

| cabling, etc. |

|

| 2. | Verify weld mode is correct for |

|

|

| processes. |

|

| 3. The power source may require |

| |

|

| calibration. |

|

| 4. | Check the actual current dis- |

|

|

| played on the Power Feed 10 vs. |

|

|

| actual current measured via exter- |

|

|

| nal meter. |

|

| 5. | Check the actual voltage dis- |

|

|

| played on the Power Feed 10 vs. |

|

|

| actual voltage measured via exter- |

|

|

| nal meter. |

|

| 6. | Check the actual WFS displayed |

|

|

| on the Power Feed 10 vs. actual |

|

|

| WFS measured via external |

|

|

| meter. |

|

|

|

| |

Excessively long and erratic arc. | 1. Check for proper configuration |

| |

|

| and implementation of voltage |

|

|

| sensing circuits. |

|

|

|

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.