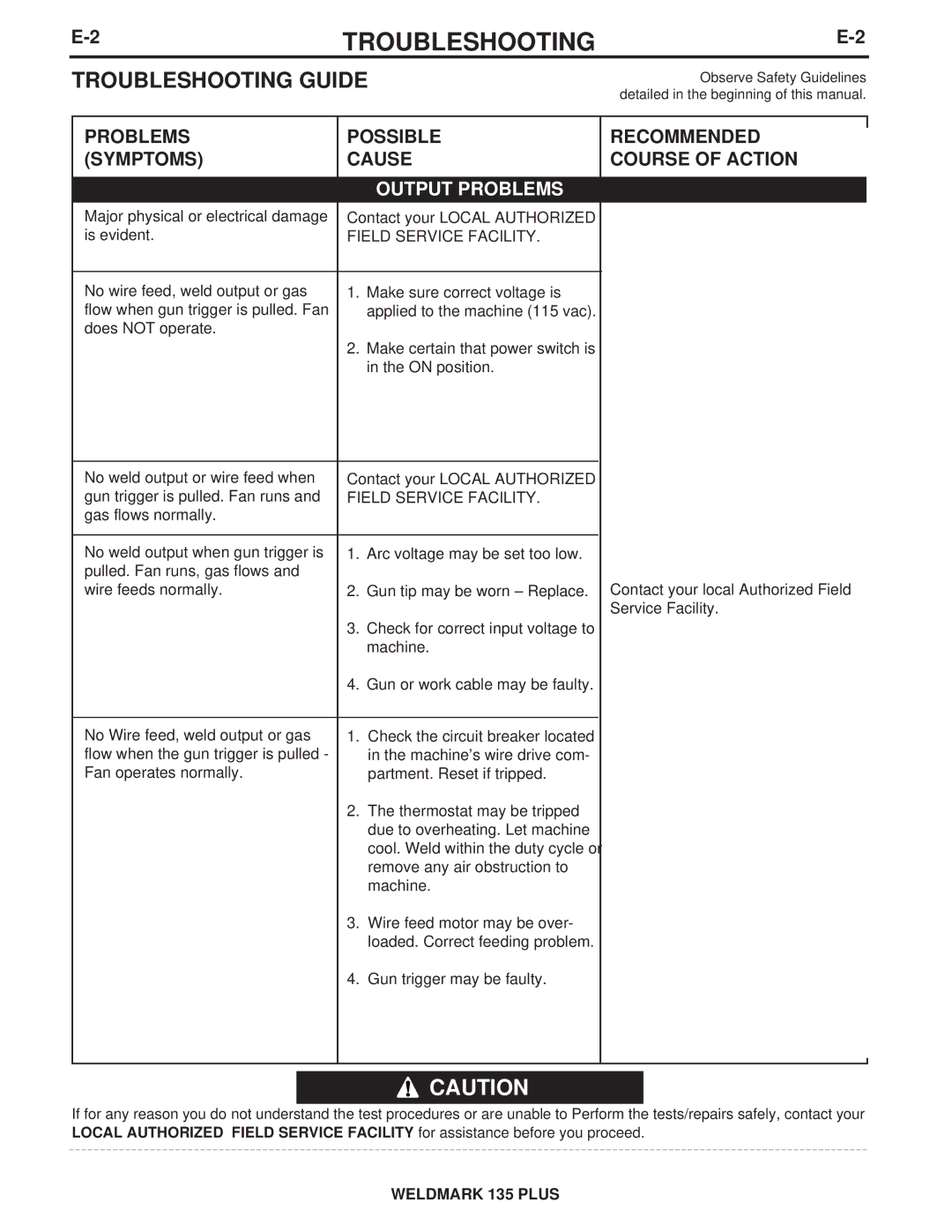

TROUBLESHOOTING |

TROUBLESHOOTING GUIDE

Observe Safety Guidelines detailed in the beginning of this manual.

| PROBLEMS | POSSIBLE | RECOMMENDED |

| (SYMPTOMS) | CAUSE | COURSE OF ACTION |

|

|

|

|

|

| OUTPUT PROBLEMS |

|

| Major physical or electrical damage | Contact your LOCAL AUTHORIZED |

|

| is evident. | FIELD SERVICE FACILITY. |

|

|

|

|

|

| No wire feed, weld output or gas | 1. Make sure correct voltage is |

|

| flow when gun trigger is pulled. Fan | applied to the machine (115 vac). |

|

| does NOT operate. |

|

|

|

| 2. Make certain that power switch is |

|

|

| in the ON position. |

|

No weld output or wire feed when | Contact your LOCAL AUTHORIZED | ||

gun trigger is pulled. Fan runs and | FIELD SERVICE FACILITY. | ||

gas flows normally. |

|

|

|

|

|

|

|

No weld output when gun trigger is | 1. | Arc voltage may be set too low. | |

pulled. Fan runs, gas flows and |

|

|

|

wire feeds normally. | 2. | Gun tip may be worn – Replace. Contact your local Authorized Field | |

|

|

| Service Facility. |

| 3. | Check for correct input voltage to | |

|

| machine. | |

| 4. | Gun or work cable may be faulty. | |

|

|

|

|

No Wire feed, weld output or gas | 1. | Check the circuit breaker located | |

flow when the gun trigger is pulled - |

| in the machine’s wire drive com- | |

Fan operates normally. |

| partment. Reset if tripped. | |

| 2. | The thermostat may be tripped | |

|

| due to overheating. Let machine | |

|

| cool. Weld within the duty cycle or | |

|

| remove any air obstruction to | |

|

| machine. | |

| 3. | Wire feed motor may be over- | |

|

| loaded. Correct feeding problem. | |

| 4. | Gun trigger may be faulty. | |

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to Perform the tests/repairs safely, contact your

LOCAL AUTHORIZED FIELD SERVICE FACILITY for assistance before you proceed.

WELDMARK 135 PLUS