INSTALLATION |

SAFETY PRECAUTIONS

![]() WARNING

WARNING

ELECTRIC SHOCK CAN KILL.

• ONLY QUALIFIED PERSONNEL

SHOULD PERFORM THIS INSTALLATION.

•Turn off input power to the power source at the disconnect switch or

fuse box before working on this equipment. Turn off the input power to any other equipment connected to the welding system at the disconnect switch or fuse box before working on the equipment.

•Do not touch electrically hot parts.

•Do not touch metal portions of the

•Do not connect the

LOCATION

The

HIGH FREQUENCY PROTECTION

![]() WARNING

WARNING

To prevent possible damage to the

Locate the

WELD CABLE CONNECTIONS

![]() WARNING

WARNING

ELECTRIC SHOCK CAN KILL.

•Only a qualified electrician should

connect the electrode leads to the LN - 15 . Connections should be made in accordance with all local and national electrical codes . Failure to do so may result in bodily injury or death.

The size of the electrode cable and work cable must be sufficient for the maximum weld current and total cable length used. To avoid interference problems with other equipment and to achieve the best possible operation, route all cables directly to the work or wire feeder. Avoid excessive lengths and do not coil excess cable. Be sure the connection to the work makes tight

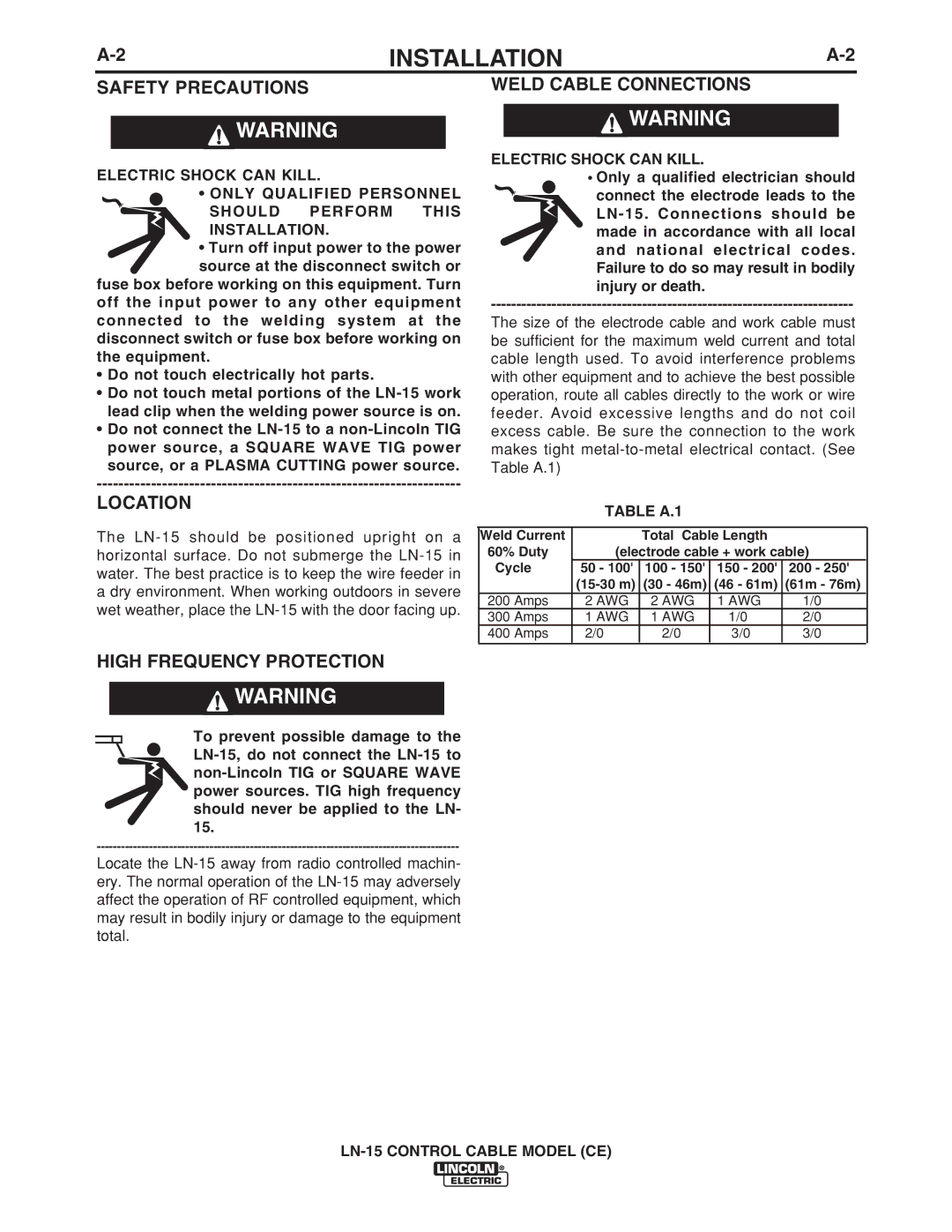

TABLE A.1

Weld Current |

| Total Cable Length |

| |

60% Duty | (electrode cable + work cable) | |||

Cycle | 50 - 100' | 100 - 150' | 150 - 200' | 200 - 250' |

| (30 - 46m) | (46 - 61m) | (61m - 76m) | |

200 Amps | 2 AWG | 2 AWG | 1 AWG | 1/0 |

300 Amps | 1 AWG | 1 AWG | 1/0 | 2/0 |

400 Amps | 2/0 | 2/0 | 3/0 | 3/0 |