| TROUBLESHOOTING |

| ||

|

|

|

|

|

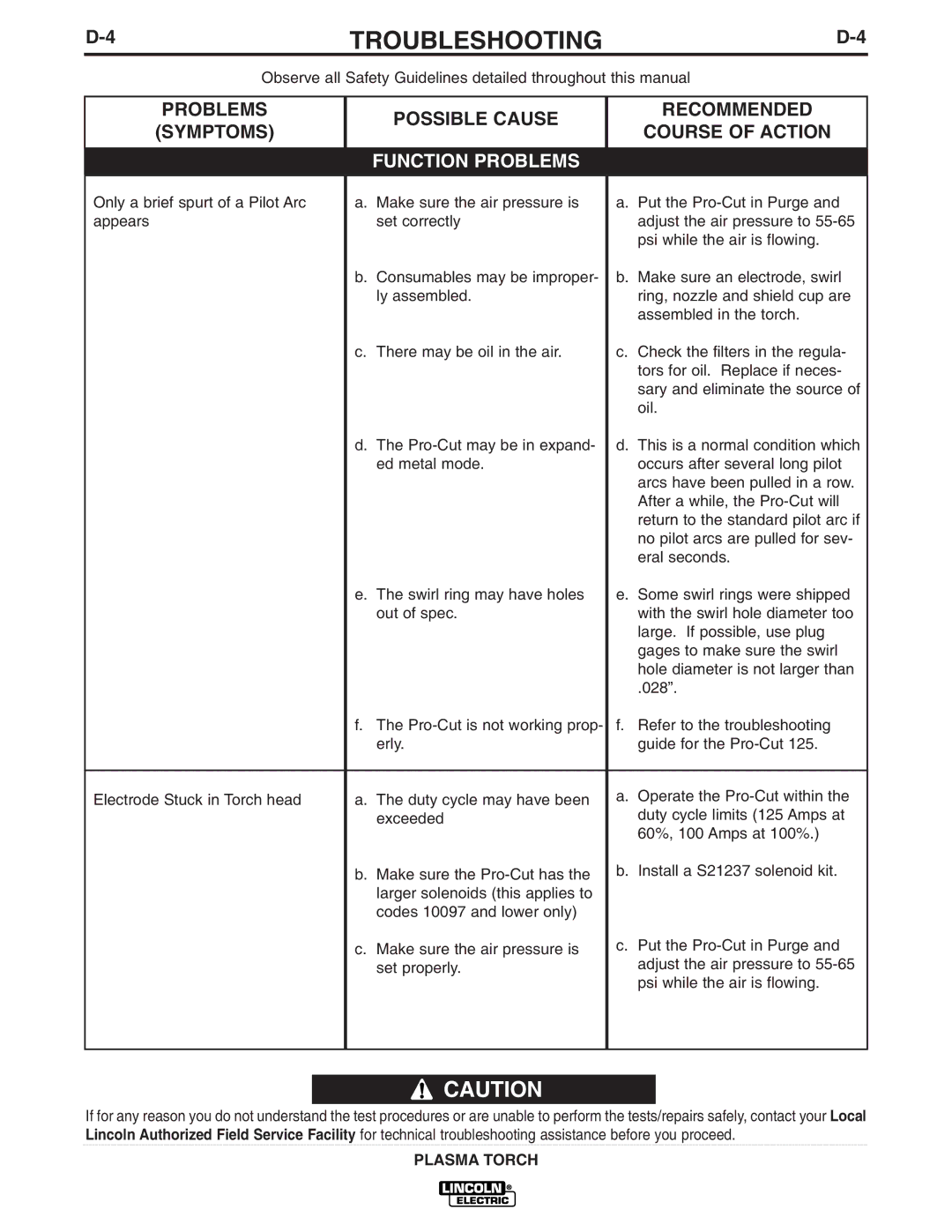

| Observe all Safety Guidelines detailed throughout this manual | |||

|

|

|

|

|

| PROBLEMS | POSSIBLE CAUSE |

| RECOMMENDED |

| (SYMPTOMS) |

| COURSE OF ACTION | |

|

|

| ||

|

|

|

|

|

|

| FUNCTION PROBLEMS |

|

|

|

|

| ||

Only a brief spurt of a Pilot Arc | a. Make sure the air pressure is | a. Put the | ||

appears | set correctly |

| adjust the air pressure to | |

|

|

|

| psi while the air is flowing. |

|

| b. Consumables may be improper- | b. Make sure an electrode, swirl | |

|

| ly assembled. |

| ring, nozzle and shield cup are |

|

|

|

| assembled in the torch. |

|

| c. There may be oil in the air. | c. Check the filters in the regula- | |

|

|

|

| tors for oil. Replace if neces- |

|

|

|

| sary and eliminate the source of |

|

|

|

| oil. |

|

| d. The | d. This is a normal condition which | |

|

| ed metal mode. |

| occurs after several long pilot |

|

|

|

| arcs have been pulled in a row. |

|

|

|

| After a while, the |

|

|

|

| return to the standard pilot arc if |

|

|

|

| no pilot arcs are pulled for sev- |

|

|

|

| eral seconds. |

|

| e. The swirl ring may have holes | e. Some swirl rings were shipped | |

|

| out of spec. |

| with the swirl hole diameter too |

|

|

|

| large. If possible, use plug |

|

|

|

| gages to make sure the swirl |

|

|

|

| hole diameter is not larger than |

|

|

|

| .028”. |

|

| f. The | f. | Refer to the troubleshooting |

|

| erly. |

| guide for the |

|

|

| ||

Electrode Stuck in Torch head | a. The duty cycle may have been | a. Operate the | ||

|

| exceeded |

| duty cycle limits (125 Amps at |

|

|

|

| 60%, 100 Amps at 100%.) |

|

| b. Make sure the | b. Install a S21237 solenoid kit. | |

|

| larger solenoids (this applies to |

|

|

|

| codes 10097 and lower only) |

|

|

|

| c. Make sure the air pressure is | c. Put the | |

|

| set properly. |

| adjust the air pressure to |

|

|

|

| psi while the air is flowing. |

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

PLASMA TORCH