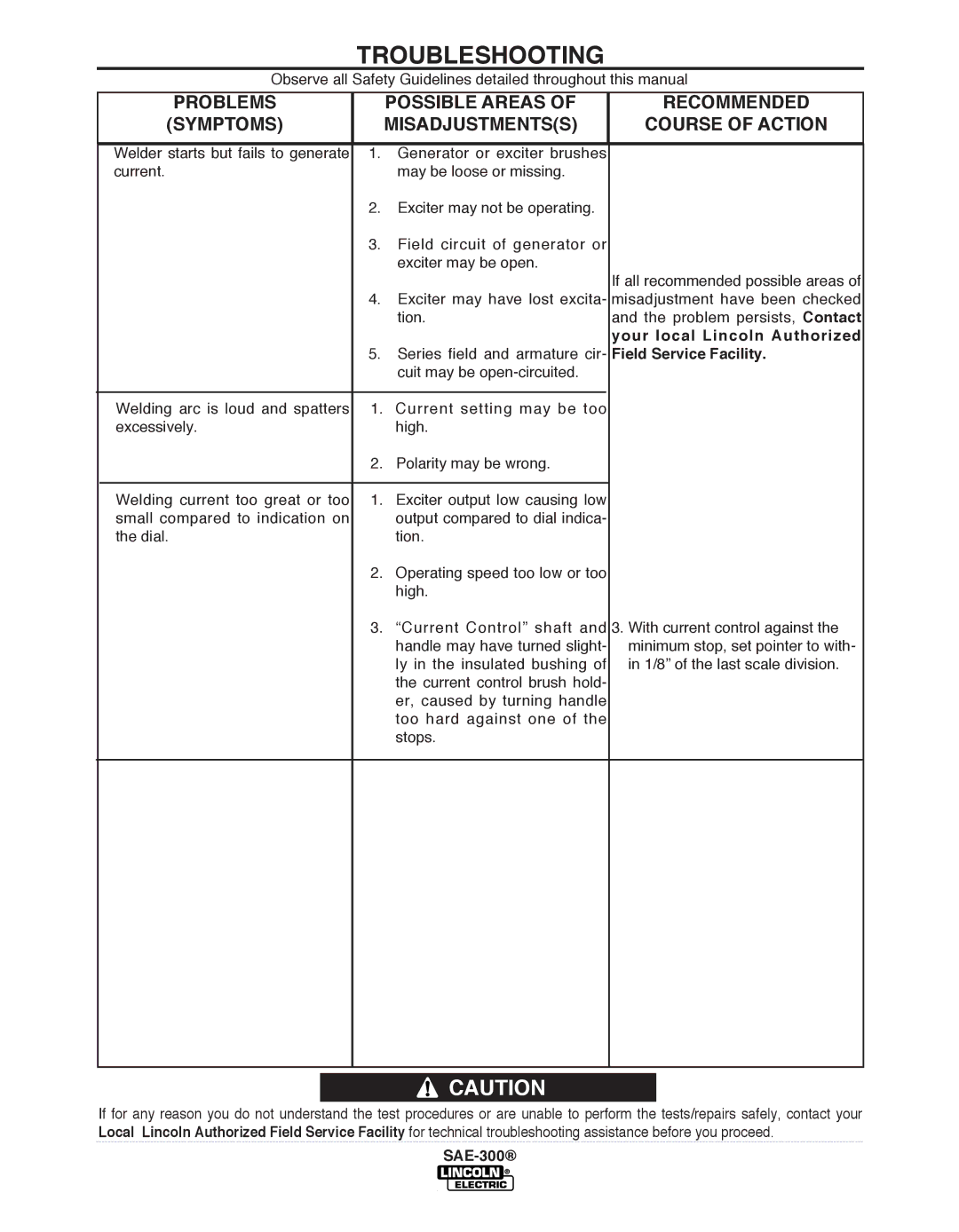

TROubLEShOOTING

Observe all Safety Guidelines detailed throughout this manual

PRObLEMS

(SYMPTOMS)

POSSIbLE AREAS OF MISADJuSTMENTS(S)

RECOMMENDED

COuRSE OF ACTION

Welder starts but fails to generate 1. | Generator or exciter brushes |

current. | may be loose or missing. |

2. | Exciter may not be operating. |

3. | Field circuit of generator or |

| exciter may be open. |

If all recommended possible areas of

4.Exciter may have lost excita- misadjustment have been checked

tion. | and the problem persists, Contact |

| your local Lincoln Authorized |

5.Series field and armature cir- Field Service Facility. cuit may be

Welding arc is loud and spatters | 1. | Current setting may be too |

excessively. |

| high. |

| 2. | Polarity may be wrong. |

|

|

|

Welding current too great or too | 1. | Exciter output low causing low |

small compared to indication on |

| output compared to dial indica- |

the dial. |

| tion. |

2.Operating speed too low or too high.

3.“Current Control” shaft and 3. With current control against the

handle may have turned slight- | minimum stop, set pointer to with- |

ly in the insulated bushing of | in 1/8” of the last scale division. |

the current control brush hold- |

|

er, caused by turning handle |

|

too hard against one of the |

|

stops. |

|

![]() CAuTION

CAuTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.