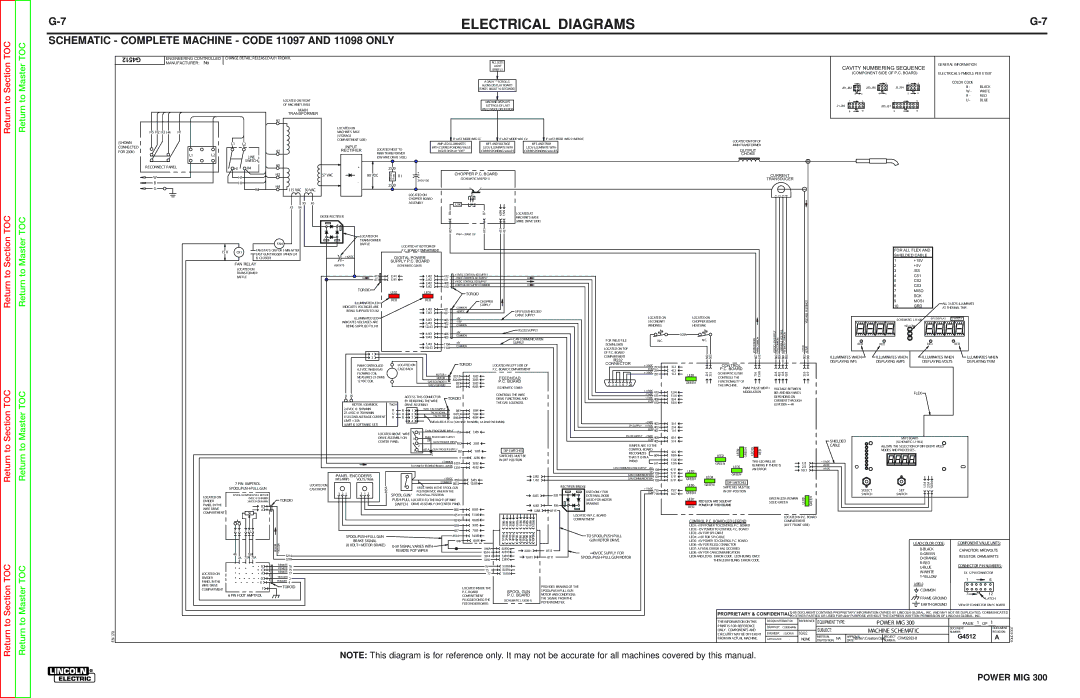

G-7 | ELECTRICAL DIAGRAMS | G-7 |

SCHEMATIC - COMPLETE MACHINE - CODE 11097 AND 11098 ONLY | | |

Return to Section

Return to Section TOC

Return to Master

Return to Master TOC

G4512

(SHOWN CONNECTED FOR 230V)

ENGINEERING CONTROLLED CHANGE DETAIL: RELEASED A.01 FROM X. | | | | | | | | | | | | | | | | | | |

MANUFACTURER: | No | | | | | | | | | | | | | | ALL LED's | | | | | | |

| | | | | | | | | | | | | | | LIGHT | | | | | | | |

| | | | | | | | | | | | | | | BRIEFLY | | | | | | |

| | | | | | | | | | | | | | A DASH "-" SCROLLS | | | | | | |

| | | | | | | | | | | | | | ALONG DISPLAY BOARD | | | | | | |

| | | | | | | | | | | | | | (TAKES ABOUT 10 SECONDS) | | | | | | |

| | | | LOCATED ON FRONT | | | | | | | | | MACHINE DISPLAYS | | | | | | |

| | | | OF MACHINE'S BASE | | | | | | | | | | | | | | |

| | | | | | | | | | | | SETTINGS OF LAST | | | | | | |

| | | | | MAIN | | | | | | | | | WELD MODE OPERATION | | | | | | |

| | | | TRANSFORMER | | | | | | | | | | | | | | | | | |

| | | | H1 | | | | | | | | | | | | | | | | | | |

| | | | | | | LOCATED ON | | | | | | | | | | | | | | | |

H5 H2 H3 H4 H1 | | | | | | | MACHINE'S BASE | | | | | | | | | | | | | | | |

| | | | | | | (STORAGE | | | | | | IF LAST MODE WAS CC | IF LAST MODE WAS CV | IF LAST MODE WAS SYNERGIC | | | | |

| | | | | | | COMPARTMENT SIDE) | | | | | | | LOCATED ON TOP OF | | |

| L1 | L2 | | | | | | | | | | AMP LED ILLUMINATES | WFS AND VOLTAGE | WFS AND TRIM | | | |

| | | | | INPUT | | | | | | MAIN TRANSFORMER | | |

| | | | | | | | | | WITH CORRESPONDING VALUE. | LED's ILLUMINATE WITH | LED's ILLUMINATE WITH | | | | |

| | | | H2 | | | RECTIFIER | LOCATED NEXT TO | RIGHT DISPLAY "OFF" | CORRESPONDING VALUES. | CORRESPONDING VALUES. | | OUTPUT | | |

L1 | L2 | | LINE | | | | | MAIN TRANSFORMER | | | | | | | | | CHOKE | | |

| | | | | (ON WIRE DRIVE SIDE) | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | |

| | SWITCH | | | | | | | | | | | | | | | | | | | |

RECONNECT PANEL | H1 | H4 | H5 | | | + | | 2520 | | | | | | | | | | | | |

| | | | | | | | | | | | | | | |

| | | | H3 | | 57 VAC | 80 VDC | ohmswatts | + | | CHOPPER P.C. BOARD | | | | | | | |

W | | H1 | | | R1 | | | | | | | CURRENT | |

| | | | | | | 500 | 50 | 2400/100 | | (SCHEMATIC M19792-1) | | | | | | | TRANSDUCER | |

| | | | | | | | | | | | | | | | | |

B | | H1 | | H4 | | | - | | 2530 | | | | | | | | | | | | |

G | | | | | | | | | | E | C | | | | | | | | |

| | H4 | | | | | | | | | | | | | | | | |

| | 115 VAC 30 VAC | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | LOCATED ON | | G | | | | | | | | 1 2 3 4 | |

| | | | | | | | | | | CHOPPER BOARD | | | | | | | | | | | |

| | | | | X5 X6 | | | | | | ASSEMBLY | | 121K | | | | | | | | | |

| | | | X3 | X4 | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | 4J99 | 1J99 | | | | | | |

| | | | | | DIODE RECTIFIER | | | | | B8 | | B7 | LOCATED AT | | | | | |

| | | | | | | | | | | | | | | MACHINE'S BASE | | | | | |

| | | | | | | | | | | | | | | | | (WIRE DRIVE SIDE) | | | | | |

| | | | | | | + | | | | | | | | | | | | | | | |

| | | | | | | | | | | | 607 | PWM = 20KHZ 12V | 615 | 431 | 437 | | | | | | |

| | | | | | | LOCATED ON | | | | | | | | | | | | | |

| | | | | | - | | | | | | | | | | | | | | |

| | | | | | TRANSFORMER | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | |

| | | | FAN | | | BAFFLE | | | | LOCATED AT BOTTOM OF | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | |

| 15 V | CR1 | FAN STAYS ON FOR 5 MIN AFTER | | | | | | P.C. BOARD COMPARTMENT | | | | | | | | | | |

| LAST GUN TRIGGER (WHEN 2/4 | | | | | | | | | | | | | | | | | | |

| | | | | + 42VDC | | | | | | | | | | | | | | | |

| | | IS CLOSED) | | | | | | DIGITAL POWER | | | | | | | | | | | |

| | | | | | + | | | | | | | | | | | | | |

| | | | | | | | SUPPLY P.C. BOARD | | | | | | | | | | | |

| FAN RELAY | | | | | | | | | | | | | | | | |

| | | | 6800/75 | | | (SCHEMATIC G3631) | | | | | | | | | | | |

| | LOCATED ON | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | |

| | TRANSFORMER | | | | | 472 | 2J41 | 1J42 | 412 | +15VDC CONTROL BD SUPPLY | | | | | | | | |

| | BAFFLE | | | | | | | | | | | | | |

| | | | | | | -15VDC CONTROL BD SUPPLY | | | | | | | | |

| | | | | | | | 471 | 1J41 | 2J42 | 411 | | | | | | | | |

| | | | | | | | +5VDC CONTROL BD SUPPLY | | | | | | | | |

| | | | | | | | | | | 3J42 | 408 | | | | | | | | |

| | | | | | | | | | | CONTROL BD SUPPLY COMMON | | | | | | | | |

| | | | | | | | | | | 5J42 | 410 | | | | | | | | |

| | | | | | | TOROID | | | | | | | | | | | | | |

| | | | | | | | LED2 | LED1 | | TOROID | | | | | | | | | |

| | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | |

| | | | | | | ILLUMINATED LED | RED | RED | | | CHOPPER | | | | | | | FEEDBACK |

| | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | SUPPLY | | | | | | | |

| | | | | | | INDICATES VOLTAGES ARE | | | | | COMMON | | | | | | | |

| | | | | | | | | 1J43 | 431 | | | | | | | | |

| | | | | | | BEING SUPPLIED TO J42 | | | +20VDC | | | | SPI FLEX/SHIELDED | | | | |

| | | | | | | | | 7J43 | 437 | | | | | | | |

| | | | | | | | | | | | | | | CABLE SUPPLY | | | | | VOLTAGE |

| | | | | | | ILLUMINATED LED | | | | | +5V | | | | | LOCATED ON | LOCATED ON | |

| | | | | | | | | 3J43 | 403 | | | | | | |

| | | | | | | INDICATES VOLTAGES ARE | | | +15V | | | | | | SECONDARY | CHOPPER BOARD | |

| | | | | | | | | 6J43 | 402 | | | | | | |

| | | | | | | BEING SUPPLIED TO J43 | | | COMMON | | | | | | WINDINGS | HEATSINK | | |

| | | | | | | | | 12J43 | 401 | | | | RS232 SUPPLY | | | |

| | | | | | | | | | | 4J43 | 406 | +5V | | | | | | | +15VDCLEMSUPPLY LEMCOMMON -VARIABLEVOLTAGE FEEBACKCOMMON | |

| | | | | | | | | | | | | | | | | 503A | |

| | | | | | | | | | | COMMON | | | | | | | |

| | | | | | | | | | | 9J43 | 405 | | | | CAN COMMUNICATION | FOR WELD FILE | N.C. | N.C. | |

| | | | | | | | | | | | | | | | |

| | | | | | | | | | | 5J43 | 1104 | +5V | | | SUPPLY | DOWNLOADS | | +PWMSIGNAL PWMCOMMON | -STUD +STUD |

| | | | | | | | | | | COMMON | | | | | |

| | | | | | | | | | | 10J43 | 1103 | | | | | LOCATED ON TOP | |

| | | | | | | | | | | | | | | | |

| | | | | | | | 1 | | | | | | | | | | OF P.C. BOARD | |

GENERAL INFORMATION

CAVITY NUMBERING SEQUENCE

| (COMPONENT SIDE OF P.C. BOARD) | ELECTRICAL SYMBOLS PER E1537 |

| 1 | 2 | 1 | 3 | 1 | 4 | COLOR CODE | |

| J81,J82 | J83,J88 | | J2,J84 | | | B - | BLACK |

| 3 | 4 | 4 | 6 | 5 | 8 | W - | WHITE |

| R - | RED |

| | | | | | |

| 1 | 5 | | 1 | | 8 | U - | BLUE |

| J1,J86 | | | J85,J87 | | | | |

| 6 | 10 | | 9 | | 16 | | |

FOR ALL FLEX AND

SHIELDED CABLE

1+15V

2+5V

3/SS

4CS1

5CS2

6CS3

7MISO

8SCK

9MOSI

| 10 | GRD | ALL 3 LED'S ILLUMINATE |

| AT THERMAL TRIP. |

| | |

| SCHEMATIC: L11108 | SPI DISPLAY | L11757-1 |

| | |

| | YELLOW | | |

RED | RED | | RED | RED |

| 2 | | | | | | | | | | | COMPARTMENT | | | | | 502 | 503 | | | | 607 | 615 | 802 | 804 | 801 | 806 | 903 | 901 |

| | | | | | | | | | | | R232 | | | | | | | | | | | | | | | | | |

| PWM CONTROLLED | | LOCATED ON | | | | TOROID | LOCATED IN LEFT SIDE OF | CONNECTOR | + 10VDC | 253 | 3J2 | | | | CONTROL | | | | | | | | | |

| 6.5 VDC WHEN GAS | | CASE BACK | | | | | | P.C. BOARD COMPARTMENT | | COM | 254 | 4J2 | | | | P.C. BOARD | | | 15J6 | | | | | | |

| FLOWING COIL | | | | | MOTOR + | | 831:B | 1J83 | | | + 10VDC | 251 | 1J2 | LED1 | 2J5 | 3J5 | (SCHEMATIC G3789) | | 7J6 | 2J8 | 4J8 | 1J8 | 6J8 | 3J9 | 1J9 |

| MEASURES 21 OHMS | | | | | | FEEDHEAD | | | | | CONTROLS THE | |

| | | | | MOTOR - | | 832:W | 2J83 | | | | | | | | | | | | | | | | |

| 12 VDC COIL | | | | | GAS SOLENOID + | | P.C. BOARD | | | | | GREEN | | | FUNCTIONALITY OF | | | | | | | | |

| | | | | | 833 | 3J83 | 2 3 4 5 6 7 20 | | | | | | | | | | | | | |

| | | | | | GAS SOLENOID - | | | | | | | | THE MACHINE. | | | | | | | | | |

| | | | | | | 834 | 4J83 | (SCHEMATIC G3883) | | | | | | | PWM: PULSE WIDTH | VOLTAGE BETWEEN | |

| | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | + 15VDC | | | | | | | | |

| | | | | | | | | | | | | 412 | 12J4 | | | | | | MODULATION | 801 AND 806 VARIES | | |

| | | | | | | | | | | CONTROLS THE WIRE | | -15VDC | | | | | | | |

B | W | | | ACCESS THIS CONNECTOR | | | | | | | | | | | | | | | |

| | TOROID | | DRIVE FUNCTIONS AND | | + 5VDC | 411 | 11J4 | | | | | | | | | DEPENDING ON | | |

| | | | BY REMOVING THE WIRE | | | COM | 408 | 8J4 | | | | | | | | | CURRENT THROUGH | |

| | | | | | | | THE GAS SOLENOID. | | 410 | 10J4 | | | | | | | | | |

| MOTOR / GEARBOX | TACH | | DRIVE ASSEMBLY | | | | | | | | | | | | | | | LEM 500A = -4V | | |

| | | | | | | | | | | | | | | | | | | | |

2.6 VDC @ 50 IN/MIN | R | R | | 1 | 5VDC TACH SUPPLY | | 841 | 1J84 | | | | | | | | | | | | | | | | | | | |

27.4 VDC @ 700 IN/MIN | U | U | | 2 | TACH SIGNAL | | 847:U | 7J84 | | | | | | | | | | | | | | | | | | | |

8 SECOND AVERAGE CURRENT | B | B | | 3 | TACH COM | | 844:B | 4J84 | | | | | | | | | | | | | | | | | | | |

LIMIT = 3.5A | | | | 4 | MEASURE B TO U (120 Hz @ 50 IN/MIN, 1.6 kHz@700 IN/MIN) | | + 5VDC | 403 | 3J4 | | | | | | | | | | | | | | |

(LIMIT IS SOFTWARE SET) | | | | | | | | | | | SPI SUPPLY | +15VDC | | | | | | | | | | | | | | |

| | | | | | | | | | | | | COM | 402 | 2J4 | | | | | | | | | | | | | | |

| LOCATED ABOVE WIRE | | DUAL PROCEDURE INPUT 853 | 3J85 | | | 401 | 1J4 | | | | | | | | | | | | | | |

| | 4 | | | | | | RS232 SUPPLY | + 5VDC | | | | | | | | | | | | | | | | |

| DRIVE ASSEMBLY ON | 3 | DUAL PROCEDURE SUPPLY | | | | 406 | 6J4 | | | | | | | | | | | | | | |

| CENTER PANEL | | 2B GUN TRIGGER INPUT | 852 | 2J85 | | | COM | 405 | 5J4 | | | | | | | | | | | | | | |

| | | | | | 2 | | | | JUMPER ARE SO THE | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | GREEN | LED10 | | | | | | | |

| | | | | 1 | 851A GUN TRIGGER SUPPLY 851 | 1J85 | DIP SWITCHES | CONTROL BOARD | | 4J6 | | | | | LED9 | RED | | | | | | |

| | | | | | 2 | | | | | SWITCHES MUST BE | RECOGNIZES | 604 | 10J6 | | | | LED2 | | | | | | |

| | | | | | | | 4 | 4J85 | THAT IT IS IN A | | | | | | | | | |

| | | | | | | | | IN OFF POSITION | | 11J6 | | | | | | | | | | | | | | |

| | | | | | COMMON 3233 | | PM300 | | | | | | | | | THIS LED WILL BE | | | | 1J3 | |

| | | | | | 3J82 | | | 611 | 12J6 | | | | GREEN | | | | | | |

| | | | | TO POWER FEEDHEADBOARD +42VDC 3234 | 4J82 | | CAN COMMUNICATION SUPPLY +5V | | | | | | | LED5 | | BLINKING IF THERE IS | | | 2J3 | |

| | | | | | | | | | | | | 0V1104 | 4J11 | LED3 | | | | | | AN ERROR | | | | | 10J3 |

PANEL ENCODERS | | | | | | | | | | 2J82 | CAN COMMUNICATION1103 | 3J11 | | LED4 | | GREEN | | | | | | | | | |

| | | | +15VDC | | | | | 1101 | 1J11 | | | | | | | | | | | | |

WFS/AMPS | VOLTS/TRIM | | | | | 855 | 5J85 | 1J82 | CAN COMMUNICATION1102 | 2J11 | GREEN | | | | | | | | | | | | | |

ILLUMINATES WHEN DISPLAYING WFS

SHIELDED

CABLE

+15VDC

+5VDC

+0VDC

ILLUMINATES WHEN | ILLUMINATES WHEN | ILLUMINATES WHEN |

DISPLAYING AMPS | DISPLAYING VOLTS | DISPLAYING TRIM |

| | | |

| FLEX | |

MSP3 BOARD

(SCHEMATIC: L11612)

ALLOWS THE SELECTION OF DIFFERENT WELD

MODES AND PROCESSES.

7 PIN AMPTROL | | | LOCATED ON | | | COMMON 8512 | 12J85 | | | | | | | | | | | | | | | | | | LED6 | DIP SWITCHES | | | |

| | | | | | 15VDC WHEN IN THE SPOOL GUN | | | | | | | | | | | | | RECTIFIER BRIDGE | | | | | GREEN | | | |

SPOOL/PUSH-PULL GUN | | | CASEFRONT | | 855A | | | | | | | | | | | | | | + 15VDCCOM | 715 | 15J7 | | SWITCHES MUST BE | | | |

| | 3 1 2 | POSITION 0VDC WHEN IN THE | | | | | | | | | | | | | | - | USED ONLY FOR | GREEN | IN OFF POSITION | | | |

SPOOL GUN/PUSH-PULL MOTOR | | | 3 2 1 | | SPOOL GUN/ PUSH-PULL POSITION | | | | | | | | | | | 5J83 | 835 | | EXTERNAL DIODE | | 716 | 16J7 | | | | GREEN |

LOCATED ON | 0VDC @ 50 IN/MIN | | TOROID | | | PUSH-PULLLOCATED TO THE RIGHT OF WIRE | | | | | | | | | | | | | | | (USED FOR MOTOR | | | | LED7 | | GREEN LED's REMAIN | LED8 |

DIVIDER | | | | | | | | | | | | | | | | | | | | | RED LED's ARE SOLID AT |

24VDC@700 IN/MIN | | | | | | | | | | | | | | | | | | | | | SOLID GREEN |

PANEL IN THE | | | | | | | SWITCH DRIVE ASSEMBLY ON CENTER PANEL | | | | | | | | | | | 6J83 | 836 | + | | BRAKING) | | | | | POWER UP THEN BLANK |

B | | | | | | | | | | | | | | | | | | | | RED | |

WIRE DRIVE | | | | | | 858 | 8J85 | | | | | | | | | | | | | | | | | | | | | |

A | | | | | | | | | | | | | | | 5J88 | 8115 | | | | | | | | | | | |

COMPARTMENT | 5K | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | 8511 | 11J85 | | | | | | | | | | | | | LOCATED IN P.C. BOARD | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | LOCATED IN P.C. BOARD |

| | | | | | | 8510 | 10J85 | | | | | | | | | | 10J86 | | | COMPARTMENT | | | | | |

| | | | | | | 1J86 | 2J86 | 3J86 | 4J86 | 6J86 | 6J86 | 7J86 | 8J86 | 9J86 | | | | | | CONTROL P.C. BOARD LED LEGEND | COMPARTMENT | |

| | | | | | | | | | | | | | |

| | | | | | | 859 | 9J85 | | | | | | | | LED1: +15V POWER TO CONTROL P.C. BOARD | (LEFT FRONT SIDE) | |

E F | C D G | | | | | | 857 | 7J85 | | | | | | | | | | | | | | | | | | LED2: -15V POWER TO CONTROL P.C. BOARD | | | |

| | | | | | | | | | | | | | | | | | | | | | LED3: +5V FOR SPI CABLE | | | |

| | | | SPOOL/PUSH-PULL GUN | | 8514 | 14J85 | 1P86 | 2P86 | 3P86 | 4P86 | 6P86 | 6P86 | 7P86 | 8P86 | 9P86 | 10P86 | | | | TO SPOOL/PUSH-PULL | | | | | | |

| | | | | | | | | | | LED4: +15V FOR SPI CABLE | | | |

| | | MOTOR + | | BRAKE SIGNAL | | 846 | 6J84 | | | | GUN MOTOR DRIVE | | | | LED5: +5V POWER TO CONTROL P.C. BOARD | | | |

| | MOTOR - | (0 VOLT= MOTOR BRAKE) | 0-5V SIGNAL VARIES WITH | | | | | | | | | | | | | | | | | | | LED6: +5V FOR RS232 CONNECTOR | | | |

| | | | | 846A | 6J810 | | | | | | | | | | | | | | | LED7: A FATAL ERROR HAS OCCURED | | | |

| | | | | REMOTE POT WIPER | | | | 2J811 | | 8115 | | | | | | | | | |

4A | 76A | | | | 8514 | 4J810 | | | | | | | +40V DC SUPPLY FOR | | | | LED8: +5V FOR CAN COMMUNICATION | | | |

| 3214 | | | | 3214 | 3J810 | | | | | | | | | | | | | | LED9 AND LED10: ERROR CODE. LED9 BLINKS ONCE | | | |

2A | 77A 75A | | | | | | | | | 1J811 | 8111 | | SPOOL/PUSH-PULL GUN MOTOR | | | | | | |

| 3218 | | | | 3218 | 2J810 | | | | | | | | | | THEN LED10 BLINKS ERROR CODE. | | | |

| | | | | | | | | | | | | | | | | | | | | | | |

| B | | REMOTE | 76 | | | | 76 | 5J810 | | | | | | | | | | | | | | | | | | | |

| C | | REMOTE | 75 | | | | 75 | 8J810 | | | | | | | | | | | | | | | | | | | |

LOCATED ON | A | | REMOTE | 77 | | | | 77 | 1J810 | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | |

DIVIDER | D | | TRIGGER 2 | | | | | | | | | | | | | | | | | | | | | | | | | | |

PANEL IN THE | E | | TRIGGER 4 | | | | | | | | | | | | | | | | | | | | | | | | | | |

WIRE DRIVE | F | | TOROID | | | | LOCATED INSIDE THE | | | | | | | | | | | PROVIDES BRAKING OF THE | | | | | | | | | |

COMPARTMENT | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | P.C. BOARD | | SPOOL GUN | | SPOOL/PUSH-PULL GUN | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | |

6 PIN FOOT AMPTROL | | | | | | | COMPARTMENT | | P.C. BOARD | | MOTOR AND CONDITIONS | | | | | | | | | |

| | | | | | | | PLUGGED ONTO THE | (SCHEMATIC L12008-1) | | THE SIGNAL FROM THE | | | | | | | | | | |

| | | | | | | | | POTENTIOMETER. | | | | | | | | | | |

| | | | | | | | FEED HEAD BOARD. | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| LEAD COLOR CODE: | COMPONENT VALUE UNITS: |

| B-BLACK | CAPACITOR: MFD/VOLTS |

| G-GREEN |

| RESISTOR: OHMS/WATTS |

| O-ORANGE |

| | |

| R-RED | CONNECTOR PIN NUMBERS: |

| U-BLUE |

| | |

| W-WHITE | EX. 12 PIN CONNECTOR |

| Y-YELLOW | 1 | 6 |

| |

| LABELS: | | |

| COMMON | | |

| FRAME GROUND | 7 | 12 |

| | LATCH |

| EARTH GROUND | VIEW OF CONNECTOR ON PC BOARD |

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OWNED BY LINCOLN GLOBAL, INC. AND MAY NOT BE DUPLICATED, COMMUNICATED

PROPRIETARY & CONFIDENTIAL:

TO OTHER PARTIES OR USED FOR ANY PURPOSE WITHOUT THE EXPRESS WRITTEN PERMISSION OF LINCOLN GLOBAL, INC.

THE INFORMATION ON THIS | DESIGN INFORMATION | REFERENCE: | EQUIPMENT TYPE: | | POWER MIG 300 | PAGE 1 | OF 1 |

PRINT IS FOR REFERENCE | DRAWN BY: | CDIEKMANN | | |

| | | | MACHINE SCHEMATIC | DOCUMENT | DOCUMENT |

ONLY. COMPONENTS AND | | SUBJECT: | | |

ENGINEER: | JZUCKER | SCALE: | | | NUMBER: | REVISION: |

CIRCUITRY MAY BE DIFFERENT | MATERIAL | | APPROVAL | PROJECT | CRM32923-B | G4512 | A |

FROM AN ACTUAL MACHINE. | | - | | NA |

APPROVED: | NONE | DISPOSITION: | Name?:Creation Date | |

| | | | DATE: | NUMBER: | | | |

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual.

POWER MIG 300