INSTALLATION | ||

|

|

|

OUTPUT CONNECTIONS

Refer to Figure A.2 for the location of the output terminals. A

OUTPUT CONNECTION FOR STICK WELDING

First determine the proper electrode polarity for the elec- trode to be used. Consult the electrode data for this infor- mation. Then connect the output cables to the output termi- nals corresponding to this polarity. For instance, for DC(+) welding, connect the electrode cable (which is connected to the electrode holder) to the “+” output terminal and the work cable (which is connected to the work clamp) to the

OUTPUT AND GAS CONNECTION FOR TIG WELDING

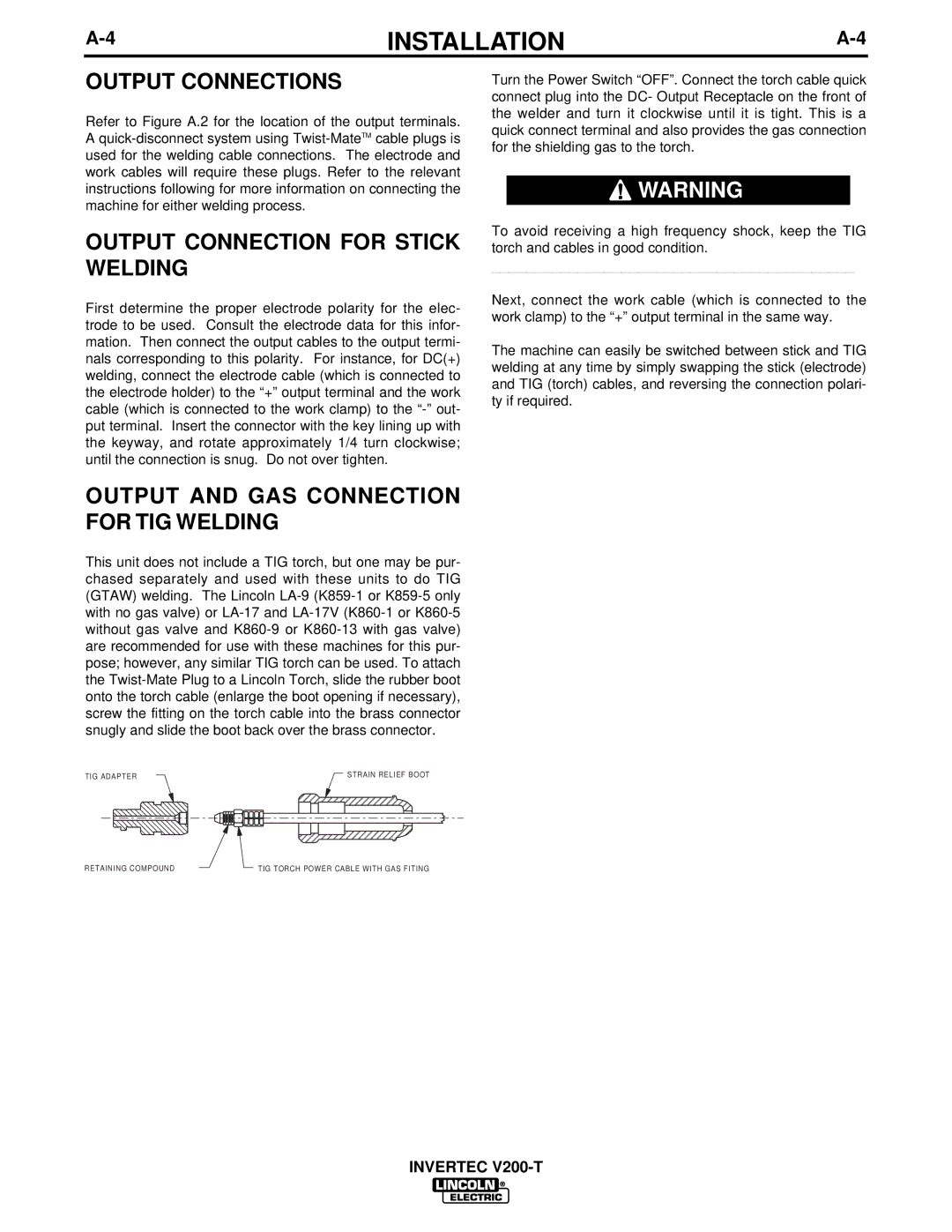

This unit does not include a TIG torch, but one may be pur- chased separately and used with these units to do TIG (GTAW) welding. The Lincoln

TIG ADAPTER |

| STRAIN RELIEF BOOT | |||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Turn the Power Switch “OFF”. Connect the torch cable quick connect plug into the DC- Output Receptacle on the front of the welder and turn it clockwise until it is tight. This is a quick connect terminal and also provides the gas connection for the shielding gas to the torch.

![]() WARNING

WARNING

To avoid receiving a high frequency shock, keep the TIG torch and cables in good condition.

__________________________________________

Next, connect the work cable (which is connected to the work clamp) to the “+” output terminal in the same way.

The machine can easily be switched between stick and TIG welding at any time by simply swapping the stick (electrode) and TIG (torch) cables, and reversing the connection polari- ty if required.

RETAINING COMPOUND | TIG TORCH POWER CABLE WITH GAS FITING |

INVERTEC