INSTALLATION |

QUICK DISCONNECT PLUG (FOR WORK CABLE)

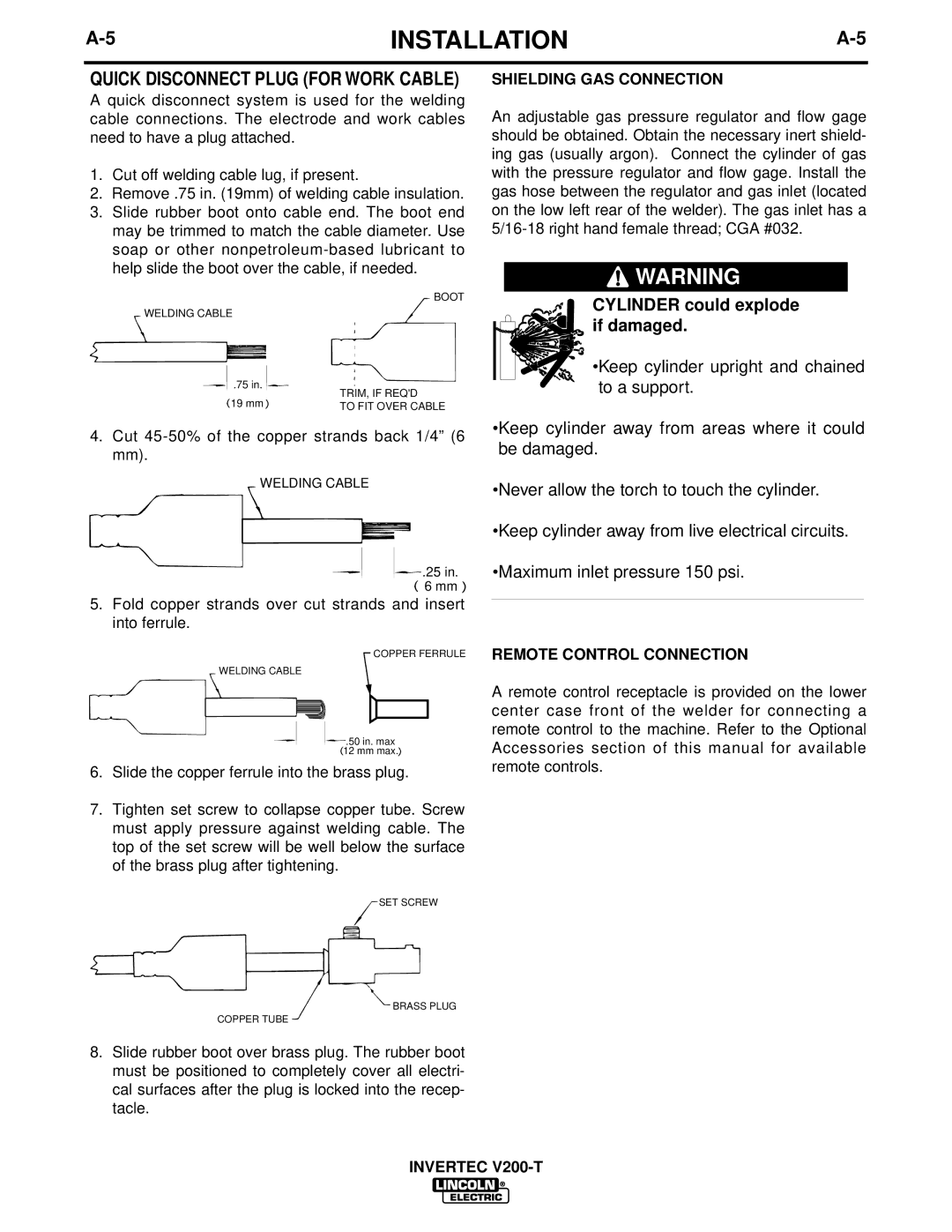

A quick disconnect system is used for the welding cable connections. The electrode and work cables need to have a plug attached.

1.Cut off welding cable lug, if present.

2.Remove .75 in. (19mm) of welding cable insulation.

3.Slide rubber boot onto cable end. The boot end may be trimmed to match the cable diameter. Use soap or other

BOOT

WELDING CABLE

.75 in. ![]()

19 mm | TRIM, IF REQ'D |

TO FIT OVER CABLE |

4.Cut

WELDING CABLE

![]()

![]() .25 in.

.25 in. ![]() 6 mm

6 mm ![]()

5.Fold copper strands over cut strands and insert into ferrule.

COPPER FERRULE

WELDING CABLE

![]() .50 in. max

.50 in. max ![]() 12 mm max.

12 mm max.

6.Slide the copper ferrule into the brass plug.

7.Tighten set screw to collapse copper tube. Screw must apply pressure against welding cable. The top of the set screw will be well below the surface of the brass plug after tightening.

SET SCREW

BRASS PLUG

COPPER TUBE

8.Slide rubber boot over brass plug. The rubber boot must be positioned to completely cover all electri- cal surfaces after the plug is locked into the recep- tacle.

SHIELDING GAS CONNECTION

An adjustable gas pressure regulator and flow gage should be obtained. Obtain the necessary inert shield- ing gas (usually argon). Connect the cylinder of gas with the pressure regulator and flow gage. Install the gas hose between the regulator and gas inlet (located on the low left rear of the welder). The gas inlet has a

![]() WARNING

WARNING

CYLINDER could explode if damaged.

•Keep cylinder upright and chained to a support.

•Keep cylinder away from areas where it could be damaged.

•Never allow the torch to touch the cylinder.

•Keep cylinder away from live electrical circuits.

•Maximum inlet pressure 150 psi.

___________________________________________

REMOTE CONTROL CONNECTION

A remote control receptacle is provided on the lower center case front of the welder for connecting a remote control to the machine. Refer to the Optional Accessories section of this manual for available remote controls.

INVERTEC