OPERATION | ||

|

|

|

EXPLANATION OF 2 STEP AND 4 STEP MODES

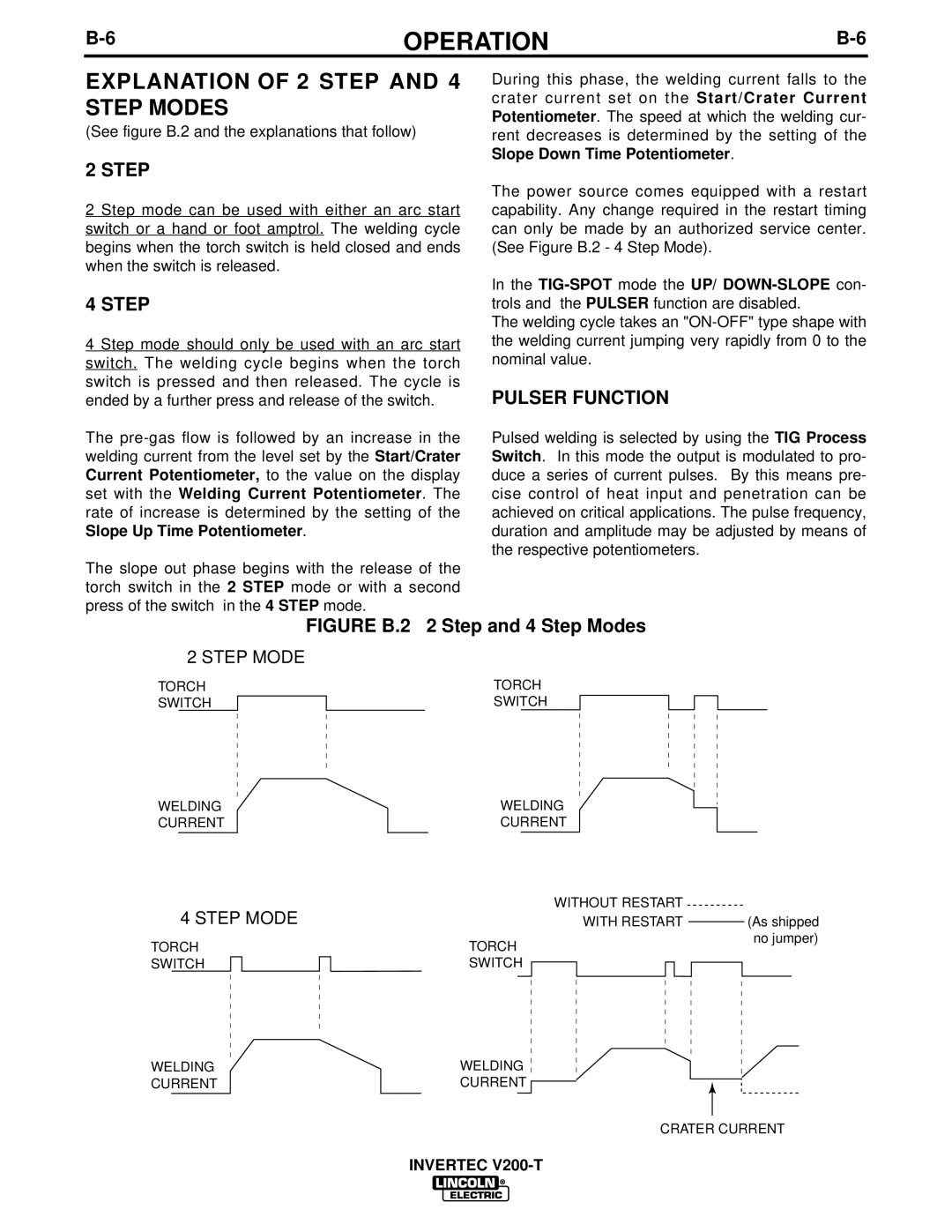

(See figure B.2 and the explanations that follow)

2 STEP

2 Step mode can be used with either an arc start switch or a hand or foot amptrol. The welding cycle begins when the torch switch is held closed and ends when the switch is released.

4 STEP

4 Step mode should only be used with an arc start switch. The welding cycle begins when the torch switch is pressed and then released. The cycle is ended by a further press and release of the switch.

The

The slope out phase begins with the release of the torch switch in the 2 STEP mode or with a second press of the switch in the 4 STEP mode.

During this phase, the welding current falls to the crater current set on the Start/Crater Current Potentiometer. The speed at which the welding cur- rent decreases is determined by the setting of the Slope Down Time Potentiometer.

The power source comes equipped with a restart capability. Any change required in the restart timing can only be made by an authorized service center. (See Figure B.2 - 4 Step Mode).

In the

The welding cycle takes an

PULSER FUNCTION

Pulsed welding is selected by using the TIG Process Switch. In this mode the output is modulated to pro- duce a series of current pulses. By this means pre- cise control of heat input and penetration can be achieved on critical applications. The pulse frequency, duration and amplitude may be adjusted by means of the respective potentiometers.

FIGURE B.2 2 Step and 4 Step Modes

2 STEP MODE

TORCH

SWITCH

TORCH SWITCH

WELDING | WELDING |

CURRENT | CURRENT |

WITHOUT RESTART

4 STEP MODE

TORCH

SWITCH

WITH RESTART |

| (As shipped | |

| |||

TORCH | no jumper) | ||

|

| ||

SWITCH |

|

| |

|

| ||

|

|

|

|

WELDING | WELDING |

CURRENT | CURRENT |

CRATER CURRENT

INVERTEC