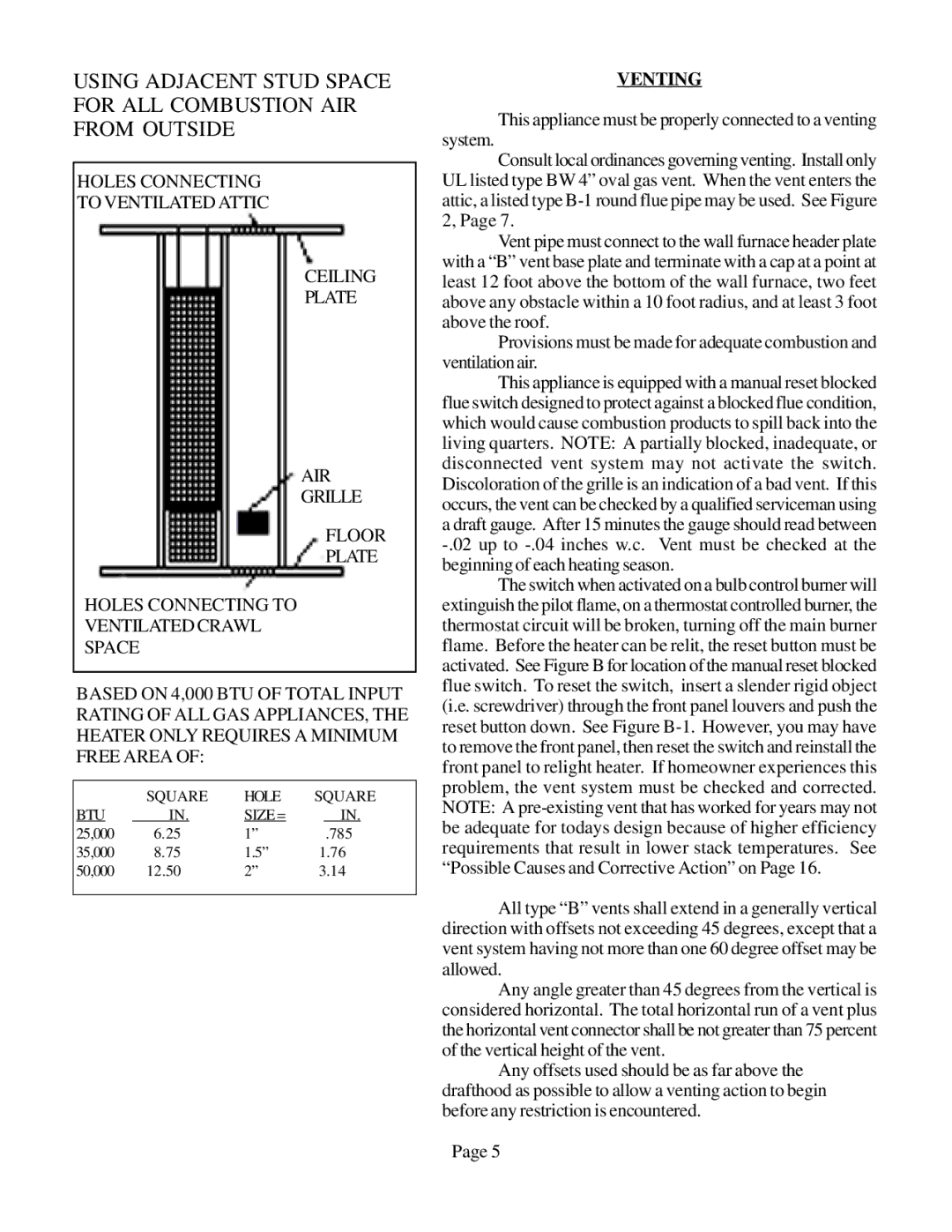

USING ADJACENT STUD SPACE FOR ALL COMBUSTION AIR FROM OUTSIDE

HOLES CONNECTING

TO VENTILATED ATTIC

CEILING

PLATE

AIR

GRILLE

FLOOR

PLATE

HOLES CONNECTING TO

VENTILATED CRAWL

SPACE

BASED ON 4,000 BTU OF TOTAL INPUT RATING OF ALL GAS APPLIANCES, THE HEATER ONLY REQUIRES A MINIMUM FREE AREA OF:

| SQUARE | HOLE | SQUARE | |||

BTU | IN. |

| SIZE = |

| IN. |

|

25,000 | 6.25 |

| 1” | .785 |

| |

35,000 | 8.75 |

| 1.5” | 1.76 |

| |

50,000 | 12.50 |

| 2” | 3.14 |

| |

|

|

|

|

|

|

|

VENTING

This appliance must be properly connected to a venting

system.

Consult local ordinances governing venting. Install only UL listed type BW 4” oval gas vent. When the vent enters the attic, a listed type

Vent pipe must connect to the wall furnace header plate with a “B” vent base plate and terminate with a cap at a point at least 12 foot above the bottom of the wall furnace, two feet above any obstacle within a 10 foot radius, and at least 3 foot above the roof.

Provisions must be made for adequate combustion and ventilation air.

This appliance is equipped with a manual reset blocked flue switch designed to protect against a blocked flue condition, which would cause combustion products to spill back into the living quarters. NOTE: A partially blocked, inadequate, or disconnected vent system may not activate the switch. Discoloration of the grille is an indication of a bad vent. If this occurs, the vent can be checked by a qualified serviceman using a draft gauge. After 15 minutes the gauge should read between

The switch when activated on a bulb control burner will extinguish the pilot flame, on a thermostat controlled burner, the thermostat circuit will be broken, turning off the main burner flame. Before the heater can be relit, the reset button must be activated. See Figure B for location of the manual reset blocked flue switch. To reset the switch, insert a slender rigid object (i.e. screwdriver) through the front panel louvers and push the reset button down. See Figure

All type “B” vents shall extend in a generally vertical direction with offsets not exceeding 45 degrees, except that a vent system having not more than one 60 degree offset may be allowed.

Any angle greater than 45 degrees from the vertical is considered horizontal. The total horizontal run of a vent plus the horizontal vent connector shall be not greater than 75 percent of the vertical height of the vent.

Any offsets used should be as far above the drafthood as possible to allow a venting action to begin before any restriction is encountered.

Page 5