WARNING: Do not bypass the blocked flue switch. To do so could expose the consumer to property damage, personal injury or possible death.

| More than 10’ | Height above any | |

| roof surface | ||

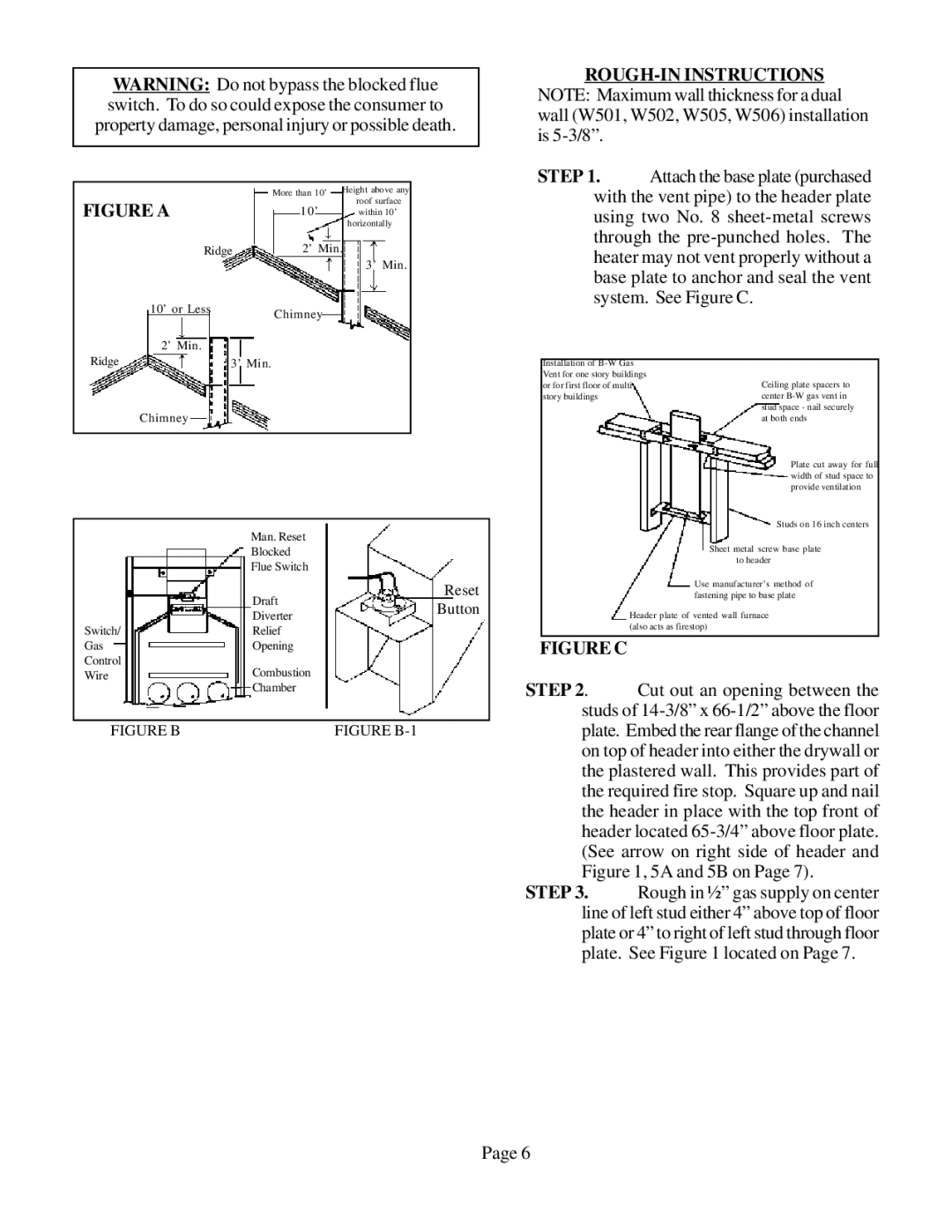

FIGURE A | 1 0 ’ | ||

within 10’ | |||

|

| horizontally | |

Ridge | 2’ Min. | ||

|

| 3’ Min. | |

10’ or Less | Chimney |

| |

|

| ||

2’ Min. |

|

| |

STEP 1. Attach the base plate (purchased with the vent pipe) to the header plate using two No. 8

Ridge | 3’ Min. |

Chimney

Man. Reset |

| |

Blocked |

| |

Flue Switch |

| |

Draft | Reset | |

Button | ||

|

Installation of

Ceiling plate spacers to center

Plate cut away for full width of stud space to provide ventilation

Studs on 16 inch centers

Sheet metal screw base plate to header

Use manufacturer’s method of fastening pipe to base plate

| Diverter |

Switch/ | Relief |

Gas | Opening |

Control | Combustion |

Wire | |

| Chamber |

|

|

FIGURE B | FIGURE |

Header plate of vented wall furnace (also acts as firestop)

FIGURE C

STEP 2. Cut out an opening between the studs of

STEP 3. Rough in ½” gas supply on center line of left stud either 4” above top of floor plate or 4” to right of left stud through floor plate. See Figure 1 located on Page 7.

Page 6