P 2/ 15

Repair

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

[1] NECESSARY REPAIRING TOOLS

Code No. | Description | Use for |

1R004 | Retaining Ring S Pliers | disassembling / assembling Ring spring 7 |

1R045 | Gear extractor | disassembling / assembling Hammer section |

1R222 | Socket Adapter | securing Ring spring 7 |

1R288 | Screwdriver magnetizer | removing Steel ball 5.6 from Spindle |

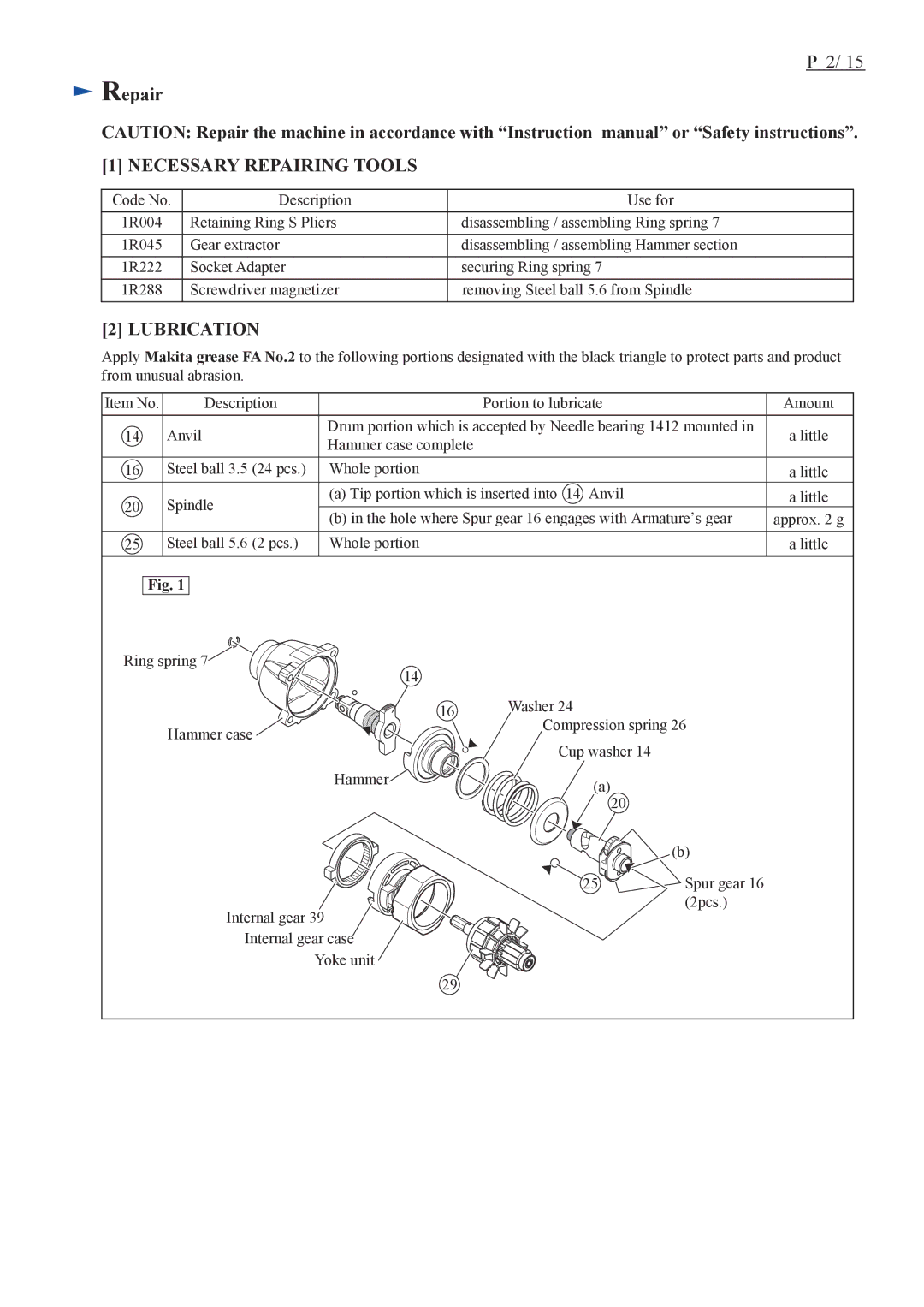

[2] LUBRICATION

Apply Makita grease FA No.2 to the following portions designated with the black triangle to protect parts and product from unusual abrasion.

Item No. | Description | Portion to lubricate | Amount | |

14 | Anvil |

| Drum portion which is accepted by Needle bearing 1412 mounted in | a little |

| Hammer case complete | |||

|

|

|

| |

|

|

|

|

|

16 | Steel ball 3.5 | (24 pcs.) | Whole portion | a little |

20 | Spindle |

| (a) Tip portion which is inserted into 14 Anvil | a little |

| (b) in the hole where Spur gear 16 engages with Armature’s gear | approx. 2 g | ||

|

|

| ||

25 | Steel ball 5.6 | (2 pcs.) | Whole portion | a little |

|

|

|

|

|

Fig. 1

Ring spring 7 |

16 | Washer 24 |

|

Hammer case | Compression spring 26 | |

Cup washer 14 |

| |

|

| |

Hammer | (a) |

|

|

| |

| 20 |

|

|

| (b) |

| 25 | Spur gear 16 |

Internal gear 39 |

| (2pcs.) |

|

| |

Internal gear case |

|

|

Yoke unit |

|

|

29 |

|

|