P 2 /12

Repair

Repair

CAUTION: Unplug the machine for safety before repair/ maintenance in accordance with the instruction manual!

[1] NECESSARY REPAIRING TOOLS

Code No. | Description | Use for | |

|

|

| |

1R004 | Retaining ring pliers | Removing/Installing Ring spring 13 from Spindle | |

1R139 | Drill chuck extractor | Locking Spindle when removing Drill chuck from Spindle | |

1R220 | Ratchet head 9.5 |

| |

1R222 | Socket adapter | Assembling Drill chuck to Spindle | |

1R223 | Torque wrench shaft 20- 90N.m | ||

Note: Preset the fastening torque of 1R223 | |||

|

| to 25- 30 N.m (250- 300kgf.cm). | |

Bit Adaptor | |||

| |||

1R231 | 1/4" Hex. shank bit for M8 |

| |

1R269 | Bearing extractor | Removing Ball bearing 606ZZ | |

1R273 | Ring spring 26 setting tool B | Removing/Installing Helical gear 35 | |

1R031 | Bearing setting pipe | Removing/Installing Ball bearing 6902ZZ |

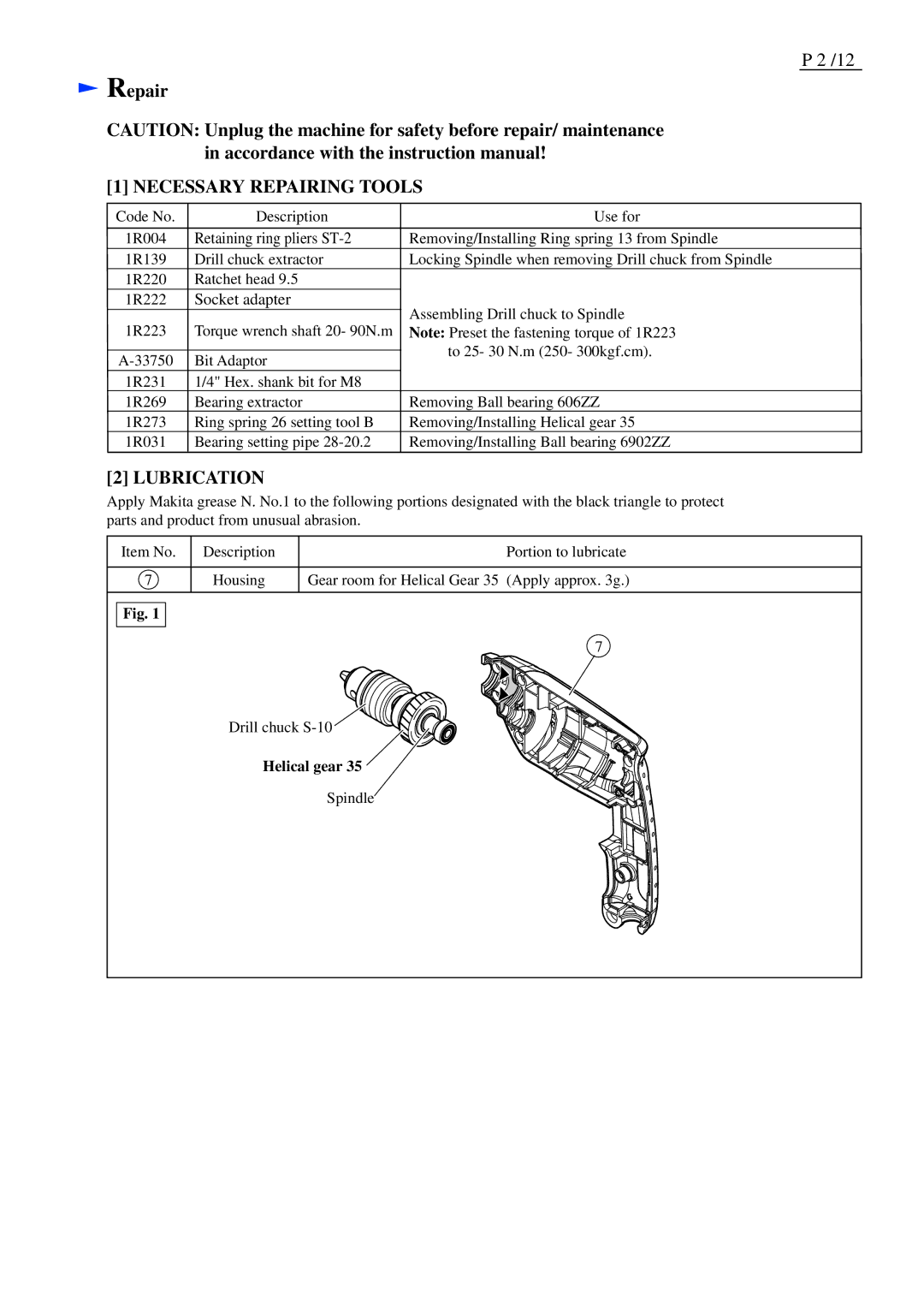

[2] LUBRICATION

Apply Makita grease N. No.1 to the following portions designated with the black triangle to protect parts and product from unusual abrasion.

| Item No. | Description | Portion to lubricate | |

|

|

|

|

|

7 |

| Housing | Gear room for Helical Gear 35 (Apply approx. 3g.) | |

|

|

|

|

|

|

|

|

|

|

| Fig. 1 |

|

|

|

|

|

|

| 7 |

|

|

|

| |

Drill chuck

Helical gear 35

Spindle