|

|

|

|

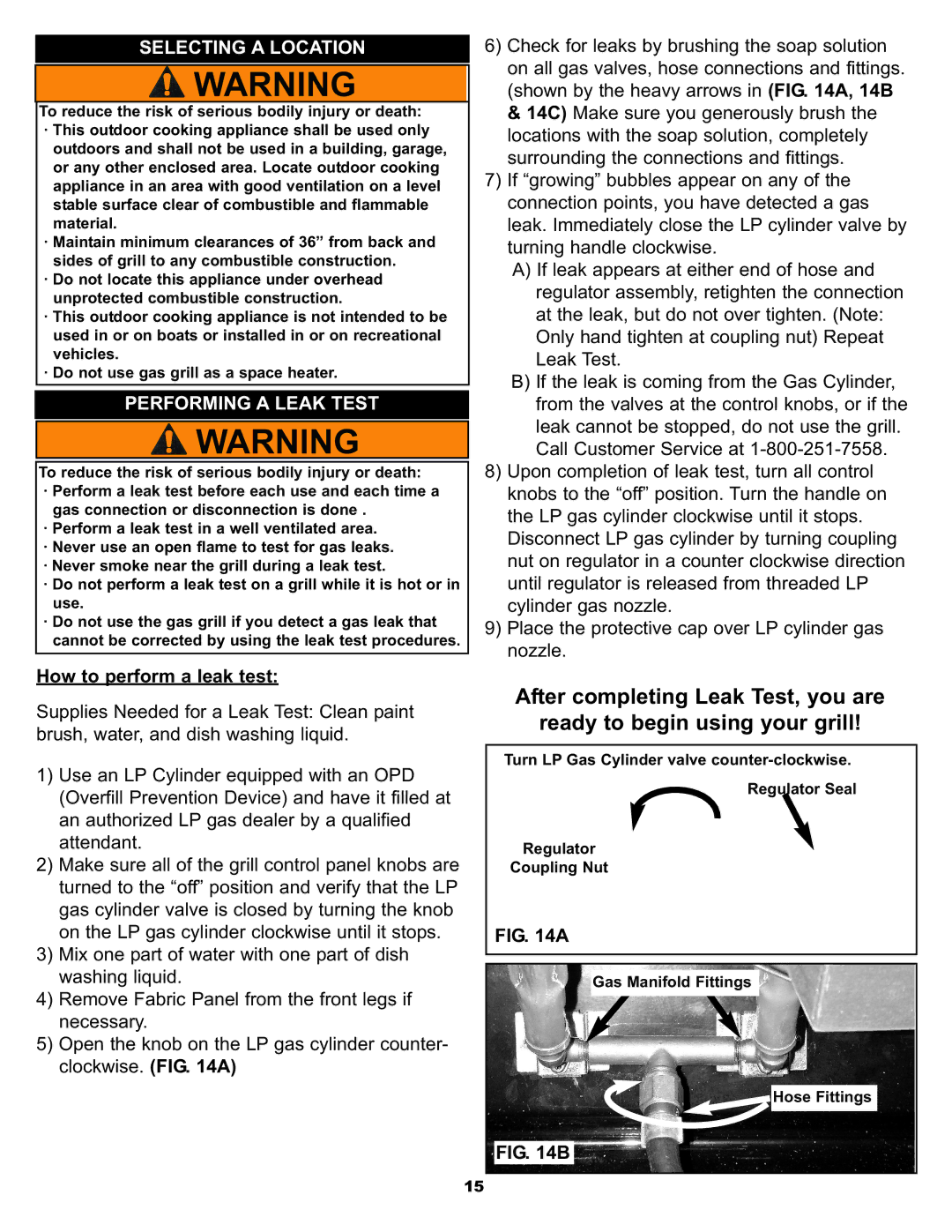

| 6) Check for leaks by brushing the soap solution | |||||||||

|

|

|

|

| ||||||||||

|

|

|

|

|

|

| on all gas valves, hose connections and fittings. | |||||||

|

|

|

|

| ||||||||||

|

|

|

|

|

|

| (shown by the heavy arrows in (FIG. 14A, 14B | |||||||

| To reduce the risk of serious bodily injury or death: |

|

|

|

| & 14C) Make sure you generously brush the | ||||||||

| ||||||||||||||

|

|

| ||||||||||||

| · This outdoor cooking appliance shall be used only |

|

|

|

| locations with the soap solution, completely | ||||||||

| outdoors and shall not be used in a building, garage, |

|

|

|

| surrounding the connections and fittings. | ||||||||

| or any other enclosed area. Locate outdoor cooking |

|

|

|

| |||||||||

| appliance in an area with good ventilation on a level |

|

| 7) If “growing” bubbles appear on any of the | ||||||||||

| stable surface clear of combustible and flammable |

|

|

|

| connection points, you have detected a gas | ||||||||

| material. |

|

|

|

| leak. Immediately close the LP cylinder valve by | ||||||||

| · Maintain minimum clearances of 36” from back and |

|

|

|

| turning handle clockwise. | ||||||||

| sides of grill to any combustible construction. |

|

|

|

| A) If leak appears at either end of hose and | ||||||||

| · Do not locate this appliance under overhead |

|

|

|

| |||||||||

| unprotected combustible construction. |

|

|

|

| regulator assembly, retighten the connection | ||||||||

| · This outdoor cooking appliance is not intended to be |

|

|

|

| at the leak, but do not over tighten. (Note: | ||||||||

| used in or on boats or installed in or on recreational |

|

|

|

| Only hand tighten at coupling nut) Repeat | ||||||||

| vehicles. |

|

|

|

| Leak Test. | ||||||||

| · Do not use gas grill as a space heater. |

|

|

|

| B) If the leak is coming from the Gas Cylinder, | ||||||||

|

|

|

| |||||||||||

|

|

|

|

|

|

| from the valves at the control knobs, or if the | |||||||

|

|

|

|

| ||||||||||

|

|

|

|

|

|

| leak cannot be stopped, do not use the grill. | |||||||

|

|

|

|

| ||||||||||

|

|

|

|

|

|

| Call Customer Service at | |||||||

|

|

|

| 8) Upon completion of leak test, turn all control | ||||||||||

| To reduce the risk of serious bodily injury or death: |

|

| |||||||||||

|

|

|

| |||||||||||

| · Perform a leak test before each use and each time a |

|

|

|

| knobs to the “off” position. Turn the handle on | ||||||||

| gas connection or disconnection is done . |

|

|

|

| the LP gas cylinder clockwise until it stops. | ||||||||

| · Perform a leak test in a well ventilated area. |

|

|

|

| |||||||||

| · Never use an open flame to test for gas leaks. |

|

|

|

| Disconnect LP gas cylinder by turning coupling | ||||||||

| · Never smoke near the grill during a leak test. |

|

|

|

| nut on regulator in a counter clockwise direction | ||||||||

| · Do not perform a leak test on a grill while it is hot or in |

|

|

|

| until regulator is released from threaded LP | ||||||||

| use. |

|

|

|

| cylinder gas nozzle. | ||||||||

| · Do not use the gas grill if you detect a gas leak that |

|

| 9) Place the protective cap over LP cylinder gas | ||||||||||

| cannot be corrected by using the leak test procedures. |

|

|

|

| nozzle. | ||||||||

| How to perform a leak test: | |||||||||||||

|

|

| After completing Leak Test, you are | |||||||||||

| Supplies Needed for a Leak Test: Clean paint |

|

| |||||||||||

| brush, water, and dish washing liquid. |

|

| ready to begin using your grill! | ||||||||||

| 1) Use an LP Cylinder equipped with an OPD |

|

| Turn LP Gas Cylinder valve |

| |||||||||

|

|

|

|

|

| Regulator Seal |

|

| ||||||

| (Overfill Prevention Device) and have it filled at |

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

| |||||||

| an authorized LP gas dealer by a qualified |

|

|

|

|

|

|

|

|

|

| |||

| attendant. |

|

| Regulator |

|

|

| |||||||

| 2) Make sure all of the grill control panel knobs are |

|

| Coupling Nut |

|

|

| |||||||

| turned to the “off” position and verify that the LP |

|

|

|

|

|

|

|

|

|

| |||

| gas cylinder valve is closed by turning th e knob |

|

|

|

|

|

|

|

|

|

| |||

| on the LP gas cylinder clockwise until it stops. |

|

|

|

|

|

|

|

|

|

| |||

|

| FIG. 14A |

|

|

|

|

|

|

| |||||

| 3) Mix one part of water with one part of dish |

|

|

|

|

|

|

|

| |||||

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

| ||||

| washing liquid. |

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

| Gas Manifold Fittings |

|

|

|

| |||||

| 4) Remove Fabric Panel from the front legs if |

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

| ||||||||

| necessary. |

|

|

|

|

|

|

|

|

|

| |||

| 5) Open the knob on the LP gas cylinder counter- |

|

|

|

|

|

|

|

|

|

| |||

| clockwise. (FIG. 14A) |

|

|

|

|

|

|

| Hose Fittings |

| ||||

15 |

| FIG. 14B |

|

|

|

|

| |||||||

|

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

| |||||