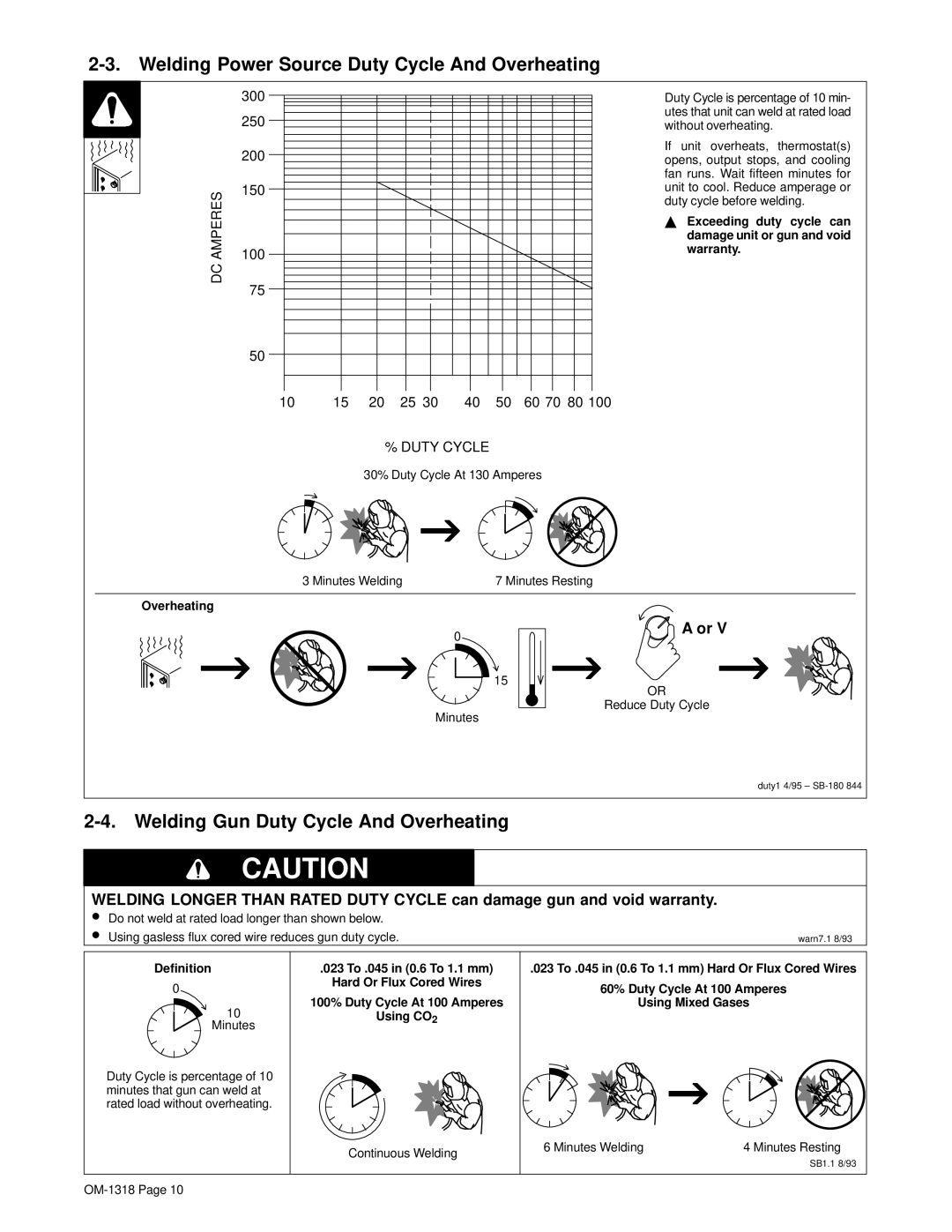

2-3. Welding Power Source Duty Cycle And Overheating

|

| 300 |

|

| 250 |

|

| 200 |

|

| |

| AMPERES | 150 |

| 100 | |

| DC | 75 |

|

| |

|

| 50 |

10 | 15 | 20 | 25 30 | 40 | 50 | 60 70 80 100 |

% DUTY CYCLE

30% Duty Cycle At 130 Amperes

Duty Cycle is percentage of 10 min- utes that unit can weld at rated load without overheating.

If unit overheats, thermostat(s) opens, output stops, and cooling fan runs. Wait fifteen minutes for unit to cool. Reduce amperage or duty cycle before welding.

YExceeding duty cycle can damage unit or gun and void warranty.

3 Minutes Welding | 7 Minutes Resting |

Overheating

0

A or V

15

OR

Reduce Duty Cycle

Minutes

duty1 4/95 –

2-4. Welding Gun Duty Cycle And Overheating

CAUTION |

WELDING LONGER THAN RATED DUTY CYCLE can damage gun and void warranty.

• | Do not weld at rated load longer than shown below. |

|

• | Using gasless flux cored wire reduces gun duty cycle. | warn7.1 8/93 |

Definition

0

10

Minutes

Duty Cycle is percentage of 10 minutes that gun can weld at rated load without overheating.

.023 To .045 in (0.6 To 1.1 mm)

Hard Or Flux Cored Wires

100% Duty Cycle At 100 Amperes

Using CO2

Continuous Welding

.023 To .045 in (0.6 To 1.1 mm) Hard Or Flux Cored Wires

60% Duty Cycle At 100 Amperes

Using Mixed Gases

6 Minutes Welding | 4 Minutes Resting |

| SB1.1 8/93 |