Tools Needed:

1

2

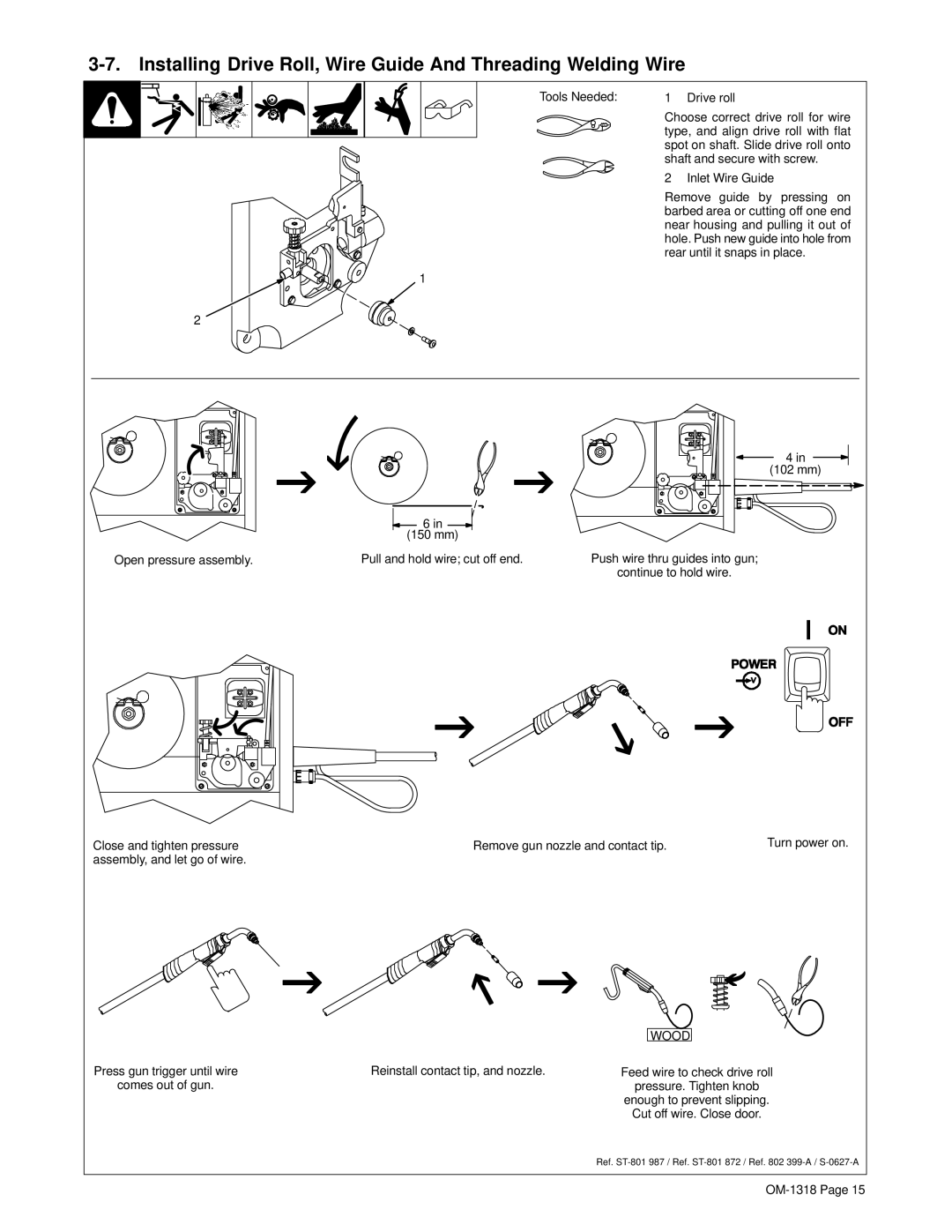

1 Drive roll

Choose correct drive roll for wire type, and align drive roll with flat spot on shaft. Slide drive roll onto shaft and secure with screw.

2 Inlet Wire Guide

Remove guide by pressing on barbed area or cutting off one end near housing and pulling it out of hole. Push new guide into hole from rear until it snaps in place.

|

| 4 in |

|

| (102 mm) |

| 6 in |

|

| (150 mm) |

|

Open pressure assembly. | Pull and hold wire; cut off end. | Push wire thru guides into gun; |

|

| continue to hold wire. |

Close and tighten pressure | Remove gun nozzle and contact tip. | Turn power on. |

assembly, and let go of wire. |

|

|

|

| WOOD |

Press gun trigger until wire | Reinstall contact tip, and nozzle. | Feed wire to check drive roll |

comes out of gun. |

| pressure. Tighten knob |

|

| enough to prevent slipping. |

|

| Cut off wire. Close door. |

|

| Ref. |