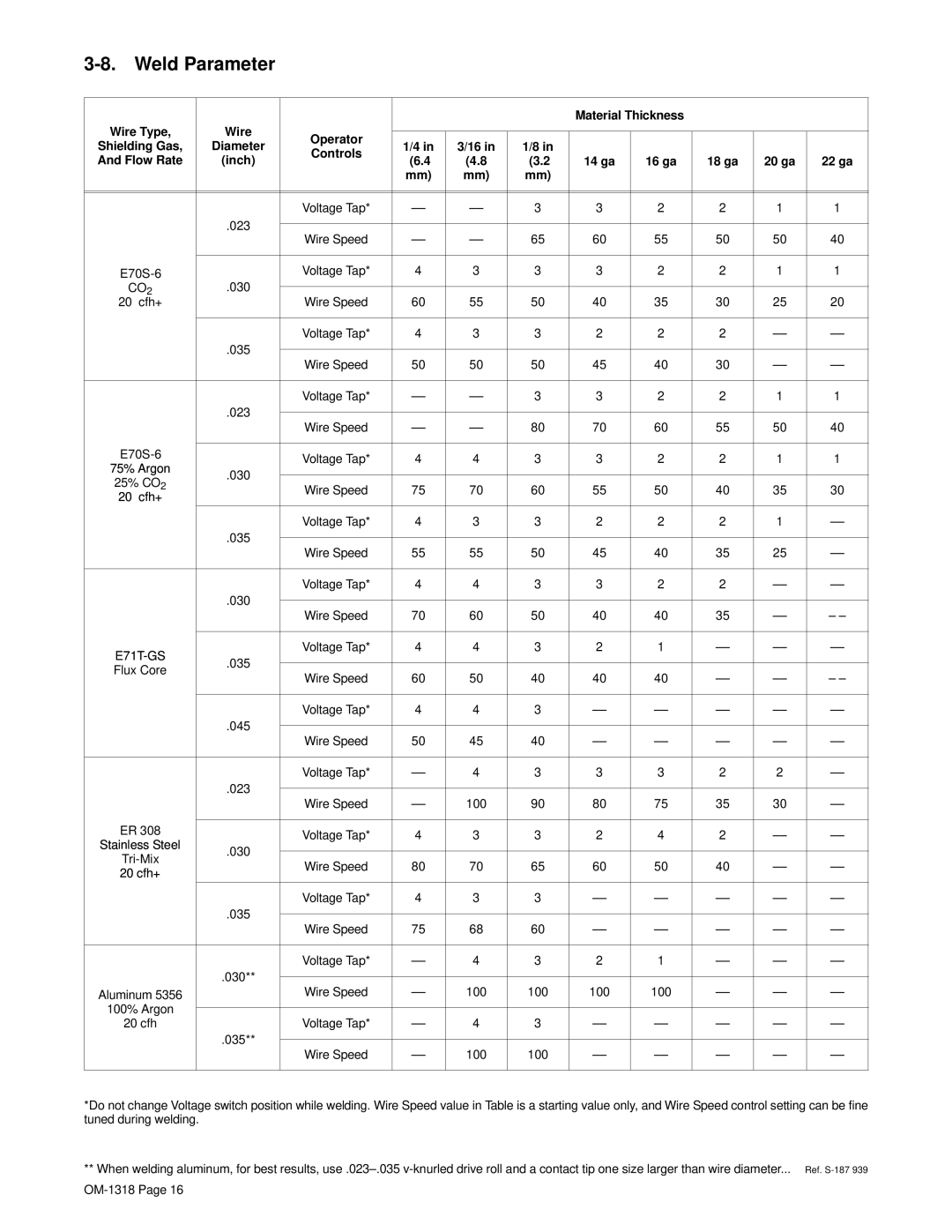

3-8. Weld Parameter

|

|

|

|

|

| Material Thickness |

|

|

| ||

Wire Type, | Wire | Operator |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| ||||

Shielding Gas, | Diameter | 1/4 in | 3/16 in | 1/8 in |

|

|

|

|

| ||

Controls |

|

|

|

|

| ||||||

And Flow Rate | (inch) | (6.4 | (4.8 | (3.2 | 14 ga | 16 ga | 18 ga | 20 ga | 22 ga | ||

| |||||||||||

|

|

| mm) | mm) | mm) |

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| |

|

| Voltage Tap* | 3 | 3 | 2 | 2 | 1 | 1 | |||

| .023 |

|

|

|

|

|

|

|

|

| |

| Wire Speed | 65 | 60 | 55 | 50 | 50 | 40 | ||||

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

| |

.030 | Voltage Tap* | 4 | 3 | 3 | 3 | 2 | 2 | 1 | 1 | ||

CO2 |

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| |||

20 cfh+ |

| Wire Speed | 60 | 55 | 50 | 40 | 35 | 30 | 25 | 20 | |

|

|

|

|

|

|

|

|

|

|

| |

|

| Voltage Tap* | 4 | 3 | 3 | 2 | 2 | 2 | |||

| .035 |

|

|

|

|

|

|

|

|

| |

| Wire Speed | 50 | 50 | 50 | 45 | 40 | 30 | ||||

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

| |

|

| Voltage Tap* | 3 | 3 | 2 | 2 | 1 | 1 | |||

| .023 |

|

|

|

|

|

|

|

|

| |

| Wire Speed | 80 | 70 | 60 | 55 | 50 | 40 | ||||

|

| ||||||||||

|

|

|

|

|

|

|

|

|

| ||

| Voltage Tap* | 4 | 4 | 3 | 3 | 2 | 2 | 1 | 1 | ||

75% Argon |

| ||||||||||

.030 |

|

|

|

|

|

|

|

|

| ||

25% CO2 | Wire Speed | 75 | 70 | 60 | 55 | 50 | 40 | 35 | 30 | ||

| |||||||||||

20 cfh+ |

|

|

|

|

|

|

|

|

|

| |

|

| Voltage Tap* | 4 | 3 | 3 | 2 | 2 | 2 | 1 | ||

| .035 |

|

|

|

|

|

|

|

|

| |

| Wire Speed | 55 | 55 | 50 | 45 | 40 | 35 | 25 | |||

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

| |

|

| Voltage Tap* | 4 | 4 | 3 | 3 | 2 | 2 | |||

| .030 |

|

|

|

|

|

|

|

|

| |

| Wire Speed | 70 | 60 | 50 | 40 | 40 | 35 | – – | |||

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

| |

|

| Voltage Tap* | 4 | 4 | 3 | 2 | 1 | ||||

.035 |

|

|

|

|

|

|

|

|

| ||

Flux Core | Wire Speed | 60 | 50 | 40 | 40 | 40 | – – | ||||

| |||||||||||

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

| |

|

| Voltage Tap* | 4 | 4 | 3 | ||||||

| .045 |

|

|

|

|

|

|

|

|

| |

| Wire Speed | 50 | 45 | 40 | |||||||

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

| |

|

| Voltage Tap* | 4 | 3 | 3 | 3 | 2 | 2 | |||

| .023 |

|

|

|

|

|

|

|

|

| |

| Wire Speed | 100 | 90 | 80 | 75 | 35 | 30 | ||||

|

| ||||||||||

ER 308 |

|

|

|

|

|

|

|

|

|

| |

| Voltage Tap* | 4 | 3 | 3 | 2 | 4 | 2 | ||||

Stainless Steel |

| ||||||||||

.030 |

|

|

|

|

|

|

|

|

| ||

Wire Speed | 80 | 70 | 65 | 60 | 50 | 40 | |||||

| |||||||||||

20 cfh+ |

| ||||||||||

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| |

|

| Voltage Tap* | 4 | 3 | 3 | ||||||

| .035 |

|

|

|

|

|

|

|

|

| |

| Wire Speed | 75 | 68 | 60 | |||||||

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

| |

|

| Voltage Tap* | 4 | 3 | 2 | 1 | |||||

| .030** |

|

|

|

|

|

|

|

|

| |

Aluminum 5356 | Wire Speed | 100 | 100 | 100 | 100 | ||||||

| |||||||||||

100% Argon |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| ||

20 cfh |

| Voltage Tap* | 4 | 3 | |||||||

| .035** |

|

|

|

|

|

|

|

|

| |

| Wire Speed | 100 | 100 | ||||||||

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

| |

*Do not change Voltage switch position while welding. Wire Speed value in Table is a starting value only, and Wire Speed control setting can be fine tuned during welding.

** When welding aluminum, for best results,