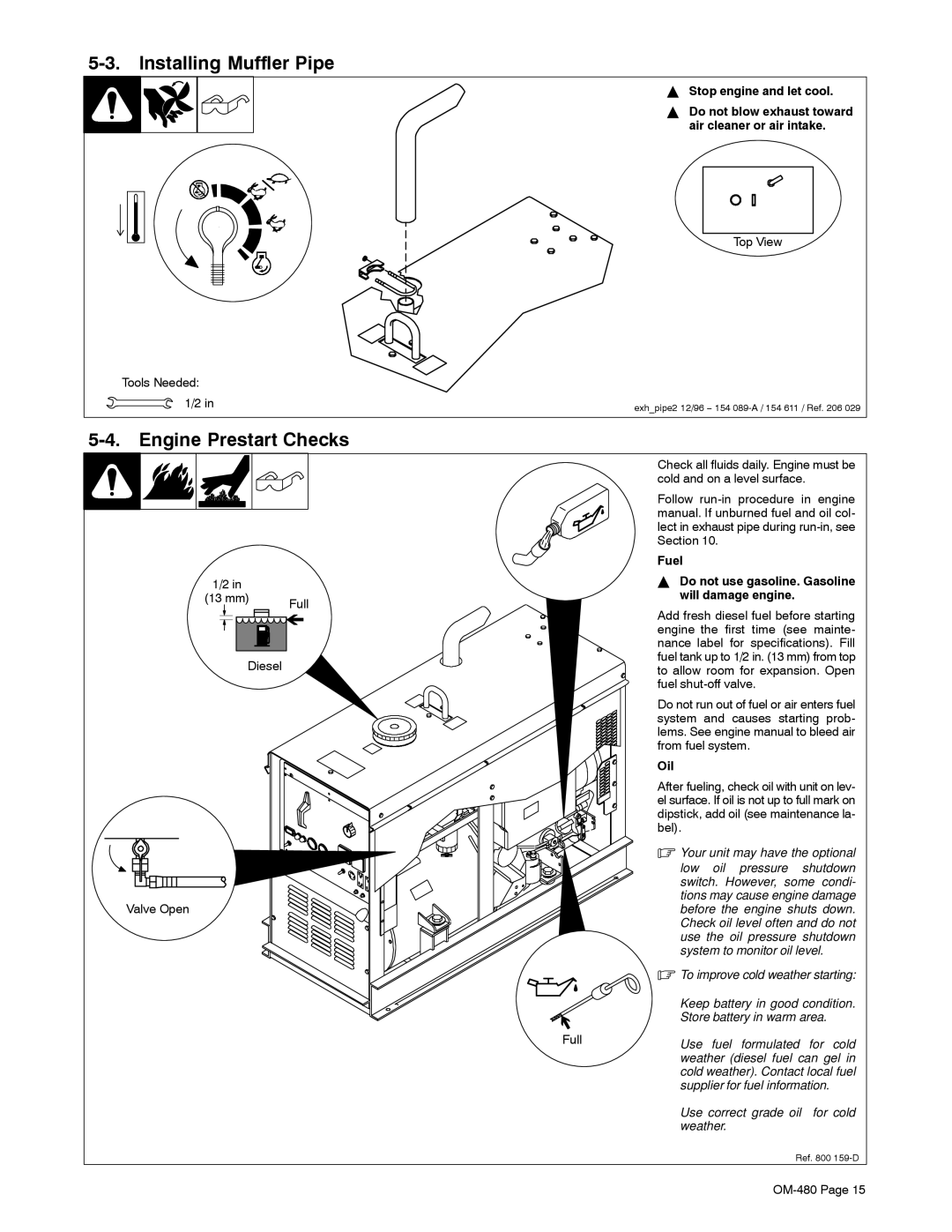

5-3. Installing Muffler Pipe

Tools Needed: 1/2 in

5-4. Engine Prestart Checks

YStop engine and let cool.

YDo not blow exhaust toward air cleaner or air intake.

Top View

exh_pipe2 12/96 − 154

1/2 in |

|

(13 mm) | Full |

| |

Diesel |

|

Valve Open

Check all fluids daily. Engine must be cold and on a level surface.

Follow

Fuel

Y Do not use gasoline. Gasoline

| will damage engine. |

|

| Add fresh diesel fuel before starting | |

| engine the first time (see mainte- | |

| nance label for specifications). Fill | |

| fuel tank up to 1/2 in. (13 mm) from top | |

| to allow room for expansion. Open | |

| fuel |

|

| Do not run out of fuel or air enters fuel | |

| system and causes starting prob- | |

| lems. See engine manual to bleed air | |

| from fuel system. |

|

| Oil |

|

| After fueling, check oil with unit on lev- | |

| el surface. If oil is not up to full mark on | |

| dipstick, add oil (see maintenance la- | |

| bel). |

|

| . Your unit may have the optional | |

| low oil pressure | shutdown |

| switch. However, some condi- | |

| tions may cause engine damage | |

| before the engine shuts down. | |

| Check oil level often and do not | |

| use the oil pressure shutdown | |

| system to monitor oil level. | |

| . To improve cold weather starting: | |

| Keep battery in good condition. | |

| Store battery in warm area. | |

Full | Use fuel formulated for cold | |

| ||

| weather (diesel fuel can gel in | |

| cold weather). Contact local fuel | |

| supplier for fuel information. | |

| Use correct grade oil | for cold |

| weather. |

|

Ref. 800