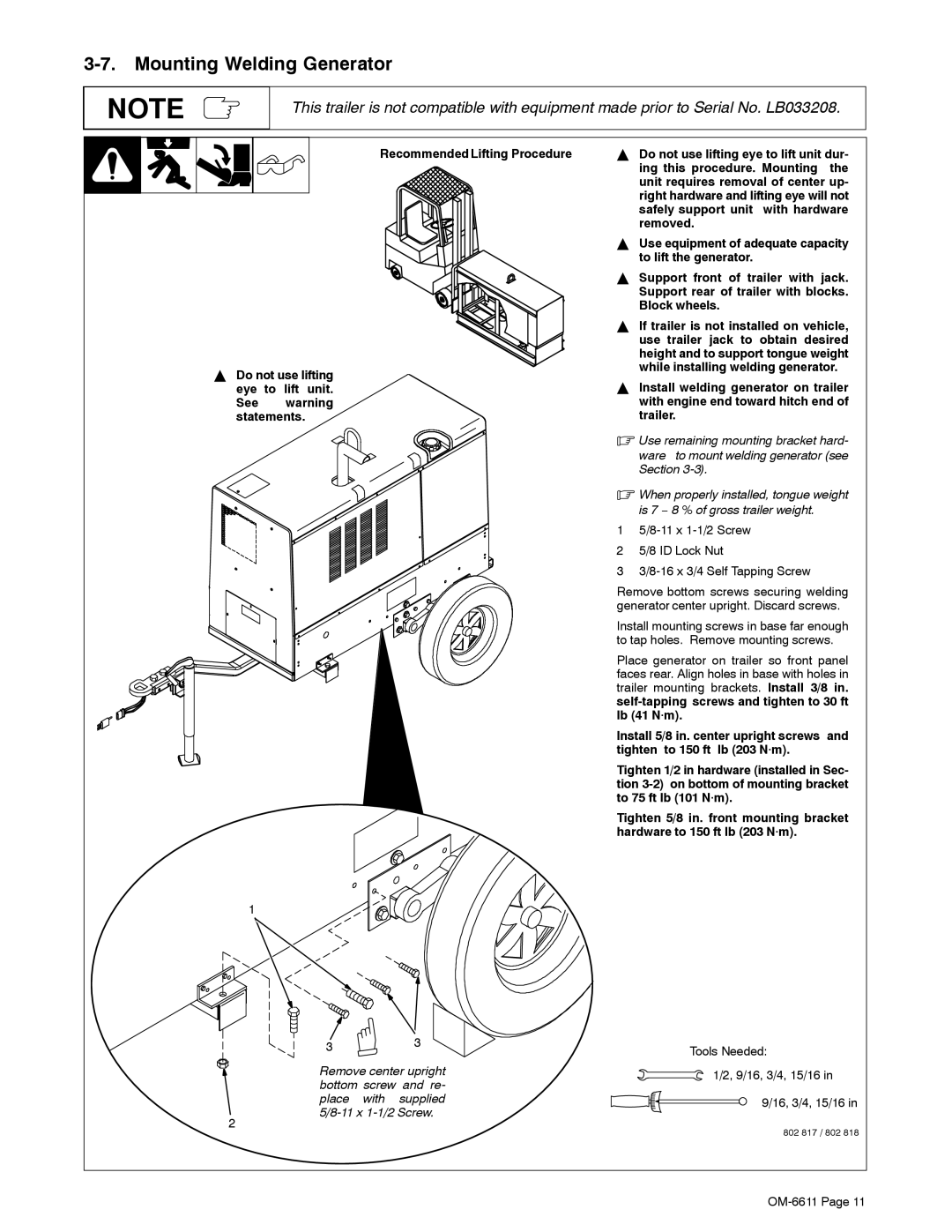

3-7. Mounting Welding Generator

NOTE

This trailer is not compatible with equipment made prior to Serial No. LB033208.

Recommended Lifting Procedure

Y Do not use lifting eye to lift unit. See warning statements.

1

YDo not use lifting eye to lift unit dur- ing this procedure. Mounting the unit requires removal of center up- right hardware and lifting eye will not safely support unit with hardware removed.

YUse equipment of adequate capacity to lift the generator.

YSupport front of trailer with jack. Support rear of trailer with blocks. Block wheels.

YIf trailer is not installed on vehicle, use trailer jack to obtain desired height and to support tongue weight while installing welding generator.

YInstall welding generator on trailer with engine end toward hitch end of trailer.

.Use remaining mounting bracket hard- ware to mount welding generator (see Section

.When properly installed, tongue weight is 7 − 8 % of gross trailer weight.

1

25/8 ID Lock Nut

3

Remove bottom screws securing welding generator center upright. Discard screws.

Install mounting screws in base far enough to tap holes. Remove mounting screws.

Place generator on trailer so front panel faces rear. Align holes in base with holes in trailer mounting brackets. Install 3/8 in.

Install 5/8 in. center upright screws and tighten to 150 ft lb (203 N.m).

Tighten 1/2 in hardware (installed in Sec- tion

Tighten 5/8 in. front mounting bracket hardware to 150 ft lb (203 N.m).

2

33

Remove center upright bottom screw and re- place with supplied

Tools Needed: ![]() 1/2, 9/16, 3/4, 15/16 in

1/2, 9/16, 3/4, 15/16 in

9/16, 3/4, 15/16 in

802 817 / 802 818