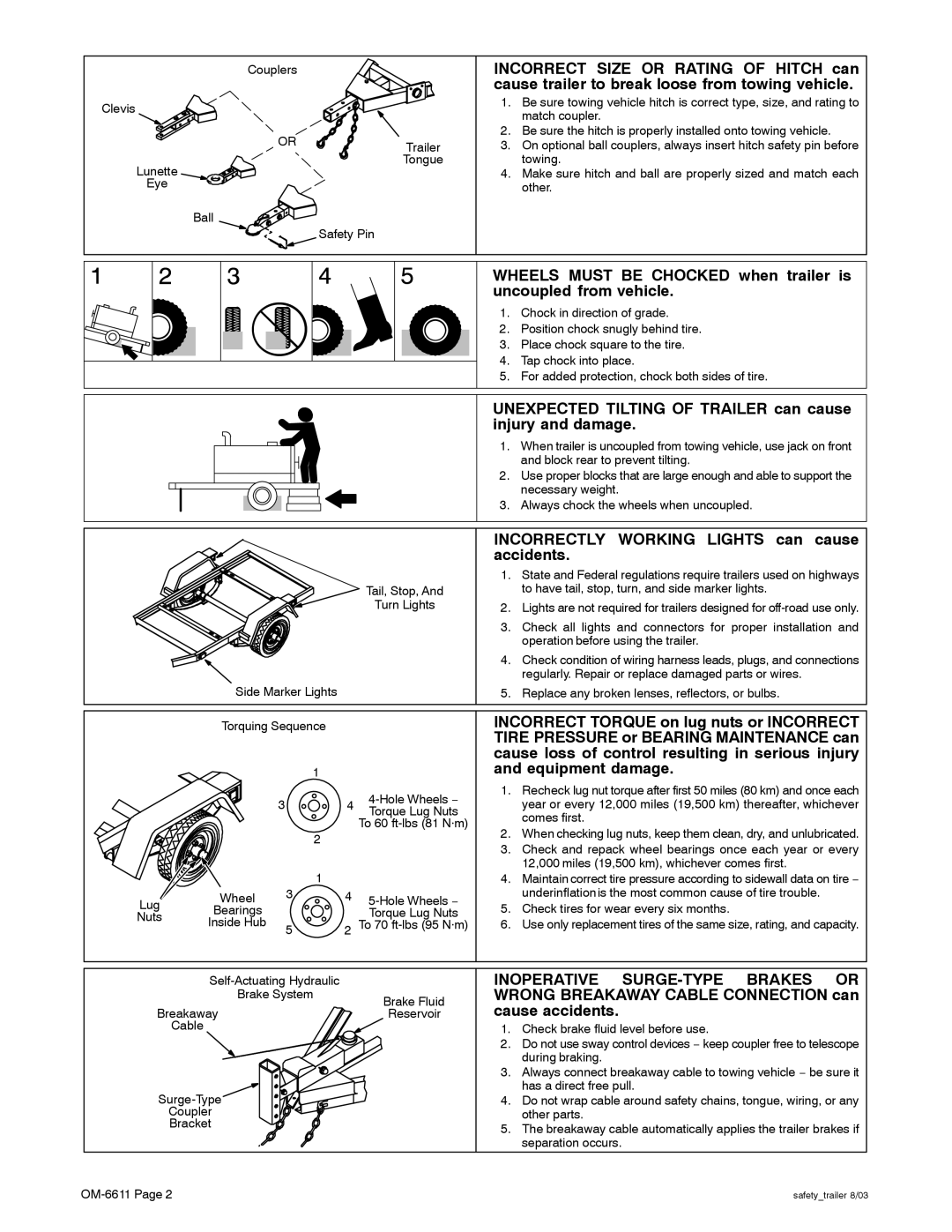

Couplers |

|

Clevis |

|

OR | Trailer |

| |

Lunette | Tongue |

| |

Eye |

|

Ball |

|

| Safety Pin |

INCORRECT SIZE OR RATING OF HITCH can cause trailer to break loose from towing vehicle.

1.Be sure towing vehicle hitch is correct type, size, and rating to match coupler.

2.Be sure the hitch is properly installed onto towing vehicle.

3.On optional ball couplers, always insert hitch safety pin before towing.

4.Make sure hitch and ball are properly sized and match each other.

WHEELS MUST BE CHOCKED when trailer is uncoupled from vehicle.

1.Chock in direction of grade.

2.Position chock snugly behind tire.

3.Place chock square to the tire.

4.Tap chock into place.

5.For added protection, chock both sides of tire.

UNEXPECTED TILTING OF TRAILER can cause injury and damage.

1.When trailer is uncoupled from towing vehicle, use jack on front and block rear to prevent tilting.

2.Use proper blocks that are large enough and able to support the necessary weight.

3.Always chock the wheels when uncoupled.

Tail, Stop, And

Turn Lights

Side Marker Lights

Torquing Sequence

|

|

| 1 |

| |

|

| 3 | 4 | ||

|

| Torque Lug Nuts | |||

|

|

|

| ||

|

|

|

| To 60 | |

|

|

| 2 |

| |

|

|

| 1 |

| |

Lug | Wheel | 3 | 4 | ||

Bearings |

|

| Torque Lug Nuts | ||

Nuts |

|

| |||

Inside Hub | 5 | 2 | To 70 | ||

| |||||

|

|

INCORRECTLY WORKING LIGHTS can cause accidents.

1.State and Federal regulations require trailers used on highways to have tail, stop, turn, and side marker lights.

2.Lights are not required for trailers designed for

3.Check all lights and connectors for proper installation and operation before using the trailer.

4.Check condition of wiring harness leads, plugs, and connections regularly. Repair or replace damaged parts or wires.

5.Replace any broken lenses, reflectors, or bulbs.

INCORRECT TORQUE on lug nuts or INCORRECT TIRE PRESSURE or BEARING MAINTENANCE can cause loss of control resulting in serious injury and equipment damage.

1.Recheck lug nut torque after first 50 miles (80 km) and once each year or every 12,000 miles (19,500 km) thereafter, whichever comes first.

2.When checking lug nuts, keep them clean, dry, and unlubricated.

3.Check and repack wheel bearings once each year or every 12,000 miles (19,500 km), whichever comes first.

4.Maintain correct tire pressure according to sidewall data on tire − underinflation is the most common cause of tire trouble.

5.Check tires for wear every six months.

6.Use only replacement tires of the same size, rating, and capacity.

| ||

Brake System | Brake Fluid | |

Breakaway | ||

Reservoir | ||

Cable |

|

![]()

Coupler

Bracket

INOPERATIVE

1.Check brake fluid level before use.

2.Do not use sway control devices − keep coupler free to telescope during braking.

3.Always connect breakaway cable to towing vehicle − be sure it has a direct free pull.

4.Do not wrap cable around safety chains, tongue, wiring, or any other parts.

5.The breakaway cable automatically applies the trailer brakes if separation occurs.

safety_trailer 8/03 |