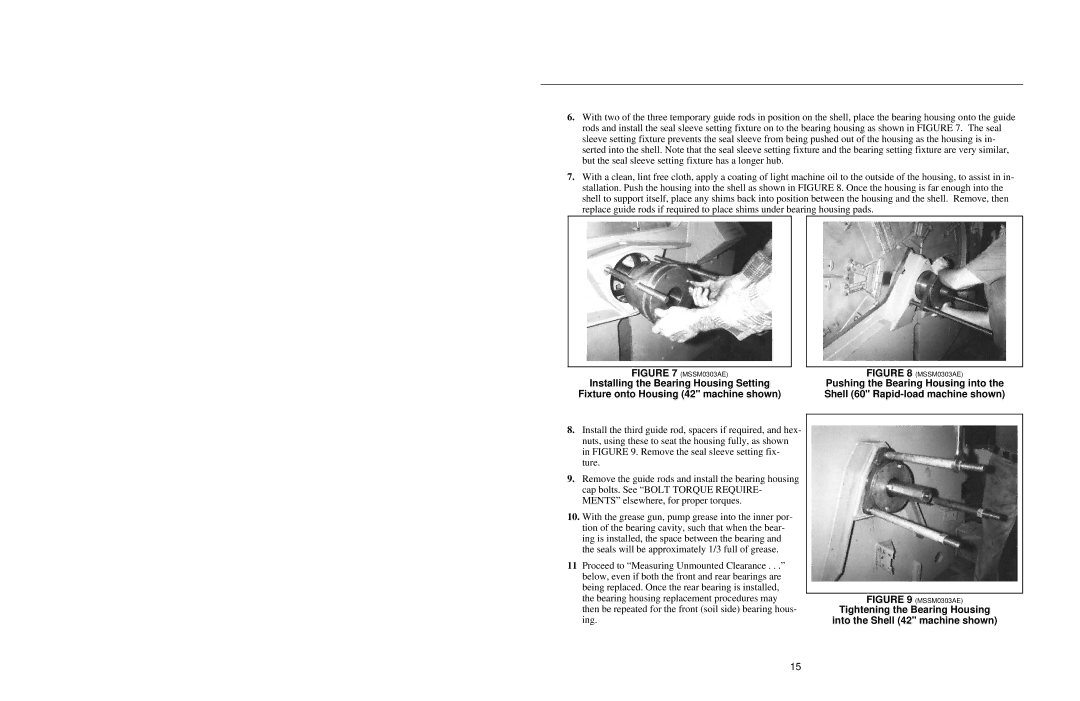

6.With two of the three temporary guide rods in position on the shell, place the bearing housing onto the guide rods and install the seal sleeve setting fixture on to the bearing housing as shown in FIGURE 7. The seal sleeve setting fixture prevents the seal sleeve from being pushed out of the housing as the housing is in- serted into the shell. Note that the seal sleeve setting fixture and the bearing setting fixture are very similar, but the seal sleeve setting fixture has a longer hub.

7.With a clean, lint free cloth, apply a coating of light machine oil to the outside of the housing, to assist in in- stallation. Push the housing into the shell as shown in FIGURE 8. Once the housing is far enough into the shell to support itself, place any shims back into position between the housing and the shell. Remove, then replace guide rods if required to place shims under bearing housing pads.

FIGURE 7 (MSSM0303AE)

Installing the Bearing Housing Setting

Fixture onto Housing (42" machine shown)

8.Install the third guide rod, spacers if required, and hex- nuts, using these to seat the housing fully, as shown in FIGURE 9. Remove the seal sleeve setting fix- ture.

9.Remove the guide rods and install the bearing housing cap bolts. See “BOLT TORQUE REQUIRE- MENTS” elsewhere, for proper torques.

10.With the grease gun, pump grease into the inner por- tion of the bearing cavity, such that when the bear- ing is installed, the space between the bearing and the seals will be approximately 1/3 full of grease.

11Proceed to “Measuring Unmounted Clearance . . .” below, even if both the front and rear bearings are being replaced. Once the rear bearing is installed, the bearing housing replacement procedures may then be repeated for the front (soil side) bearing hous- ing.

FIGURE 8 (MSSM0303AE)

Pushing the Bearing Housing into the Shell (60"

FIGURE 9 (MSSM0303AE)

Tightening the Bearing Housing into the Shell (42" machine shown)

15