Belt Tension Measurements

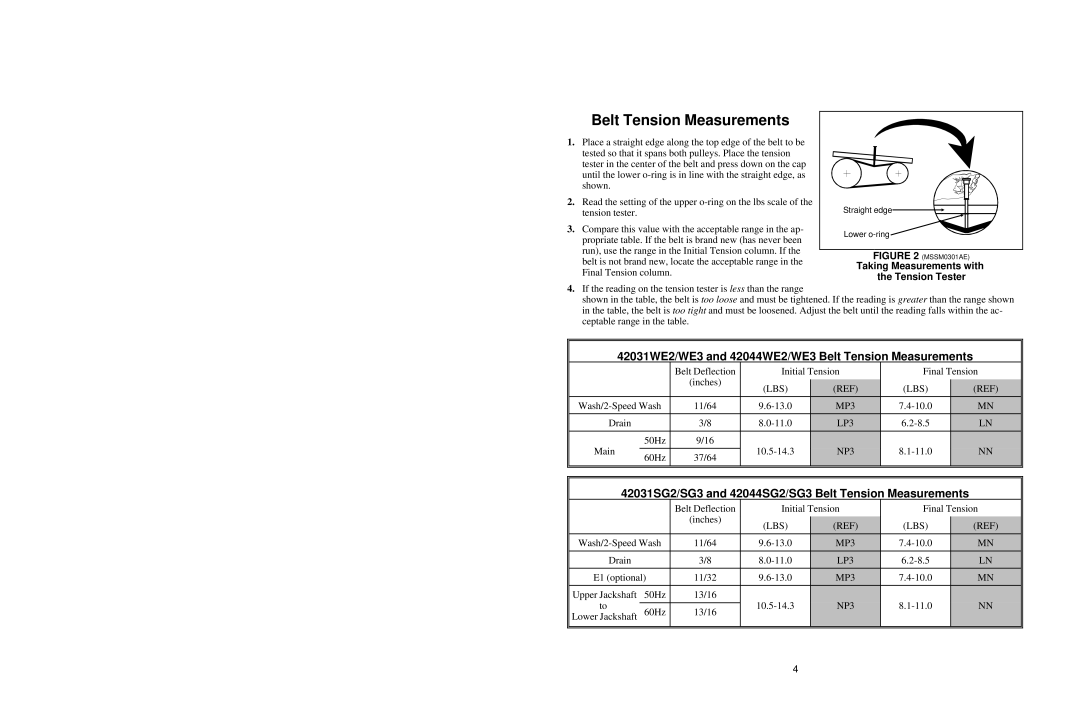

1.Place a straight edge along the top edge of the belt to be tested so that it spans both pulleys. Place the tension tester in the center of the belt and press down on the cap until the lower

2.Read the setting of the upper

3.Compare this value with the acceptable range in the ap- propriate table. If the belt is brand new (has never been run), use the range in the Initial Tension column. If the belt is not brand new, locate the acceptable range in the Final Tension column.

Straight edge |

Lower |

FIGURE 2 (MSSM0301AE)

Taking Measurements with the Tension Tester

4.If the reading on the tension tester is less than the range

shown in the table, the belt is too loose and must be tightened. If the reading is greater than the range shown in the table, the belt is too tight and must be loosened. Adjust the belt until the reading falls within the ac- ceptable range in the table.

42031WE2/WE3 and 42044WE2/WE3 Belt Tension Measurements

|

| Belt Deflection | Initial Tension | Final Tension | |||

|

| (inches) |

|

|

|

| |

|

| (LBS) | (REF) | (LBS) | (REF) | ||

|

|

| |||||

11/64 | MP3 | MN | |||||

Drain | 3/8 | LP3 | LN | ||||

Main | 50Hz | 9/16 | NP3 | NN | |||

|

| ||||||

60Hz | 37/64 | ||||||

|

|

|

|

| |||

|

|

|

|

|

|

| |

42031SG2/SG3 and 42044SG2/SG3 Belt Tension Measurements

|

| Belt Deflection | Initial Tension | Final Tension | |||

|

| (inches) |

|

|

|

| |

|

| (LBS) | (REF) | (LBS) | (REF) | ||

|

|

| |||||

11/64 | MP3 | MN | |||||

Drain |

| 3/8 | LP3 | LN | |||

E1 (optional) | 11/32 | MP3 | MN | ||||

Upper Jackshaft | 50Hz | 13/16 |

|

|

|

| |

to |

|

| NP3 | NN | |||

60Hz | 13/16 | ||||||

Lower Jackshaft |

|

|

|

| |||

|

|

|

|

|

|

| |

4