Assembling the Water

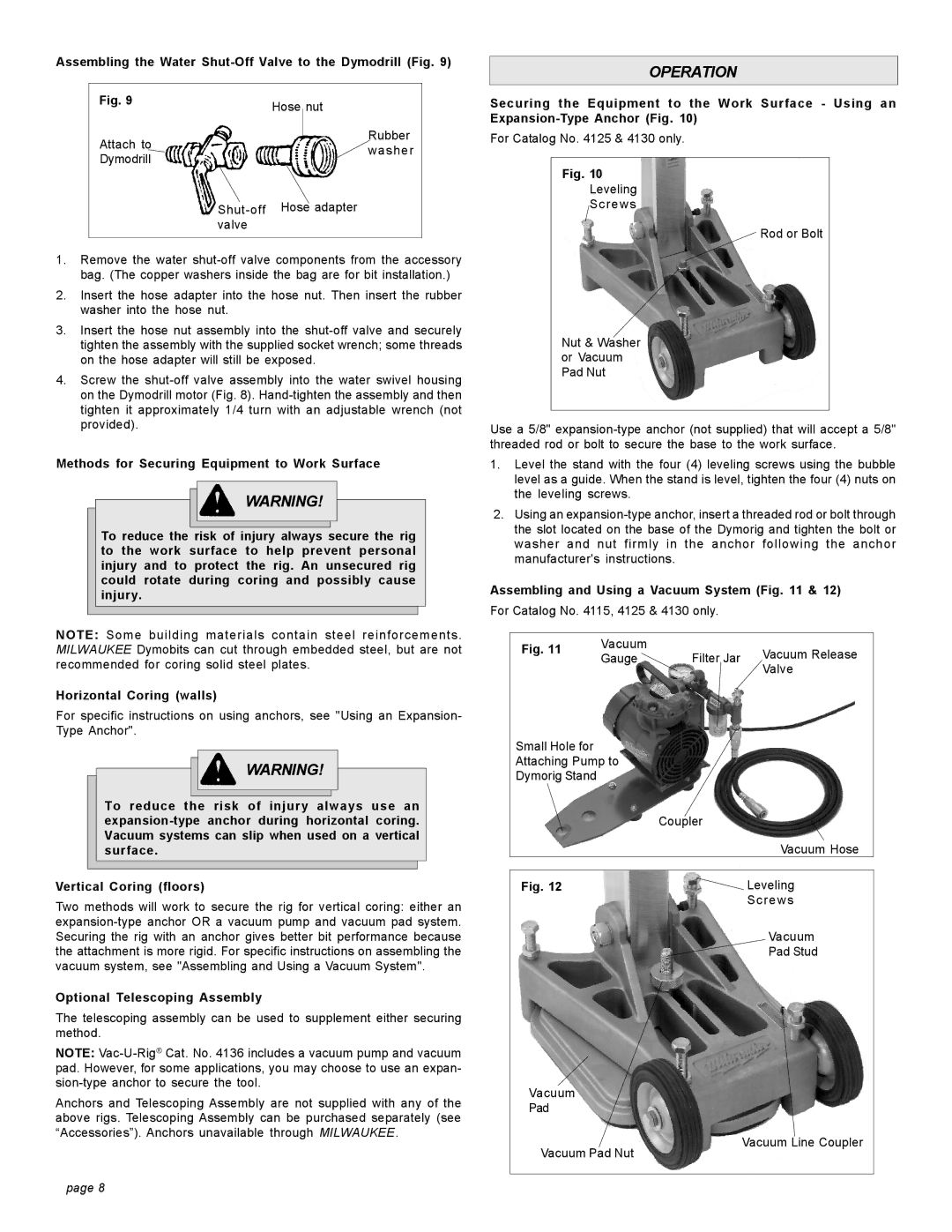

Fig. 9 | Hose nut |

|

Rubber

Attach towasher Dymodrill

1.Remove the water

2.Insert the hose adapter into the hose nut. Then insert the rubber washer into the hose nut.

3.Insert the hose nut assembly into the

4.Screw the

Methods for Securing Equipment to Work Surface

WARNING!

To reduce the risk of injury always secure the rig to the work surface to help prevent personal injury and to protect the rig. An unsecured rig could rotate during coring and possibly cause injury.

NOTE: Some building materials contain steel reinforcements. MILWAUKEE Dymobits can cut through embedded steel, but are not recommended for coring solid steel plates.

Horizontal Coring (walls)

For specific instructions on using anchors, see "Using an Expansion- Type Anchor".

WARNING!

To reduce the risk of injury always use an

Vertical Coring (floors)

Two methods will work to secure the rig for vertical coring: either an

OPERATION

Securing the Equipment to the Work Surface - Using an

For Catalog No. 4125 & 4130 only.

Fig. 10

Leveling

Screws

Rod or Bolt

Nut & Washer or Vacuum Pad Nut

Use a 5/8"

1.Level the stand with the four (4) leveling screws using the bubble level as a guide. When the stand is level, tighten the four (4) nuts on the leveling screws.

2.Using an

Assembling and Using a Vacuum System (Fig. 11 & 12)

For Catalog No. 4115, 4125 & 4130 only.

Fig. 11 | Vacuum | Filter Jar | Vacuum Release | |

Gauge | ||||

| ||||

|

|

| Valve |

Small Hole for

Attaching Pump to

Dymorig Stand

Coupler

Vacuum Hose

Fig. 12 | Leveling |

| Screws |

Securing the rig with an anchor gives better bit performance because the attachment is more rigid. For specific instructions on assembling the vacuum system, see "Assembling and Using a Vacuum System".

Optional Telescoping Assembly

The telescoping assembly can be used to supplement either securing method.

NOTE:

Anchors and Telescoping Assembly are not supplied with any of the above rigs. Telescoping Assembly can be purchased separately (see “Accessories”). Anchors unavailable through MILWAUKEE.

Vacuum

Pad

Vacuum Pad Nut

Vacuum

Pad Stud

Vacuum Line Coupler

page 8