6509-31, 6519-30 specifications

Milwaukee has long been a leader in the power tool industry, known for its durability and innovative technology. Among its standout offerings are the Milwaukee 6509-31 and 6519-30, two powerful tools tailored for professional users looking for versatility and performance.The Milwaukee 6509-31 is a compact band saw designed for cutting metal, which is particularly favored among electricians, plumbers, and HVAC professionals. This model features a powerful 10-amp motor that delivers impressive cutting performance while maintaining a lightweight profile. One of its standout features is the tool-free blade changing mechanism, allowing for quick and efficient blade replacement without the need for additional tools. Users appreciate the ergonomically designed handle, which provides a comfortable grip and reduces fatigue during prolonged use.

Additionally, the Milwaukee 6509-31 is equipped with a built-in LED light that illuminates the cutting area, enhancing visibility in dimly lit environments. Its variable speed control enables users to adjust the cutting speed according to the material being cut, making it suitable for different applications. The saw is also designed with a durable housing that protects its internal components, ensuring longevity even in demanding jobsite conditions.

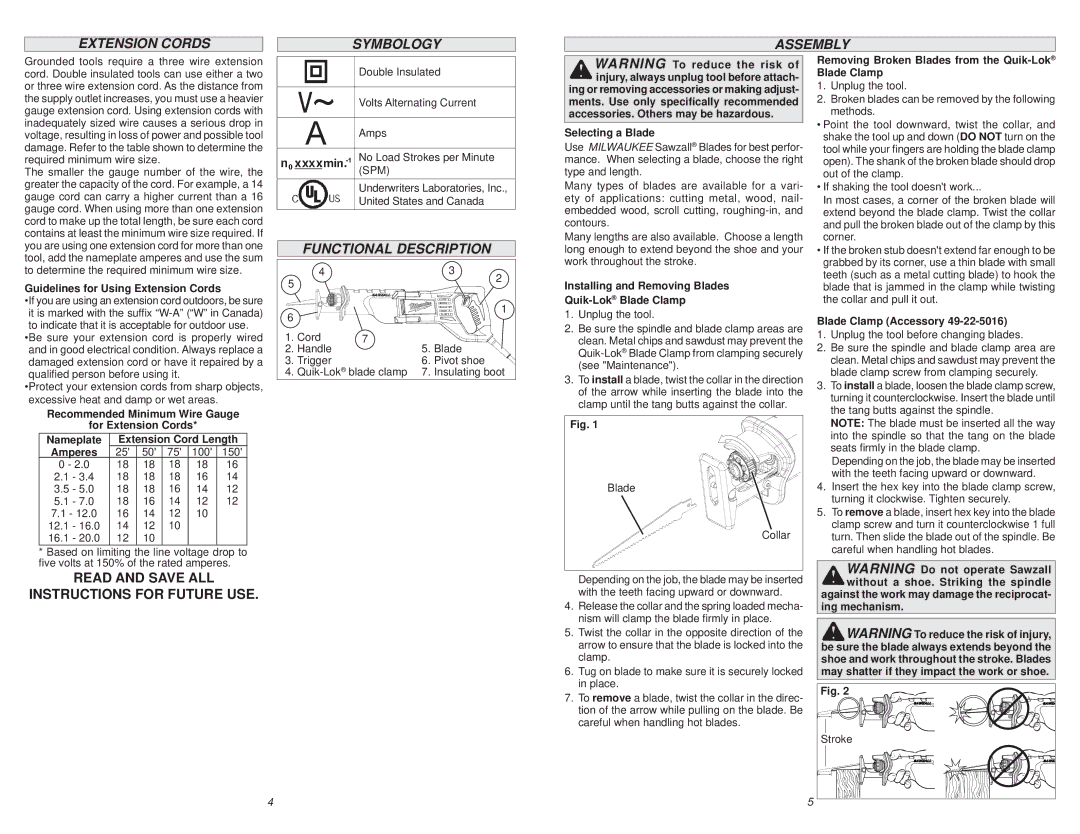

On the other hand, the Milwaukee 6519-30 is a powerful, corded reciprocating saw that has gained popularity among contractors and DIY enthusiasts alike. This model features a robust 12-amp motor that delivers exceptional cutting speed and efficiency. A key characteristic of the 6519-30 is its adjustable stroke length, which allows for versatility in cutting various materials, from wood to metal.

The saw includes a unique counterbalance mechanism that minimizes vibration and maximizes control during operation. An easy-to-use, tool-free blade clamp makes it simple for users to switch between blade types, further enhancing its practicality. The integrated dust blower keeps the cutting line clear, providing users with a better view of their work.

Both models are designed with Milwaukee’s signature REDLINK PLUS Intelligence, an advanced technology that ensures optimal performance and protects against overloads. This feature enhances durability and safety, making them reliable choices for heavy-duty tasks.

In summary, the Milwaukee 6509-31 and 6519-30 represent the brand's commitment to providing high-quality, innovative tools designed for professional users. Their powerful motors, user-friendly features, and advanced technologies make them indispensable additions to any contractor's toolkit, ensuring high performance and durability on any job site.