General Operation

Always clamp the workpiece securely on a

5. If the saw binds and stalls, maintain |

a firm grip and release the trigger im- |

mediately. Hold the saw motionless in |

APPLICATIONS

saw horse or bench (Fig. 13). See “APPLICA- TIONS” for the correct way to support your work in different situations.

Fig. 13

the workpiece until the blade comes to |

a complete stop. |

6. After finishing a cut, be sure the lower |

guard closes and the blade comes to a |

complete stop before setting the saw |

down. |

Electric Brake (Cat. No. 6394)

Select models feature an electronic brake. The brake engages when the trigger is re-

WARNING

To reduce the risk of injury, wear safety goggles or glasses with side shields. Unplug the tool before changing accessories or making adjustments.

Selecting

The

1.Draw a cutting line. Place the front of the shoe on the edge of the workpiece without making blade contact. Hold the

Fig. 14

2.Line up the sight line with your cutting line. Position your arms and body to resist KICKBACK. Pull the trigger, allow- ing the motor to reach full speed before beginning to cut.

3.While cutting, keep the shoe flat against the workpiece and maintain a firm grip. Do not force the saw through the workpiece. Forcing a saw can cause

KICKBACK.

4.If making a partial cut, restarting in

leased, causing the blade to stop and allow- ing you to proceed with your work. Generally, the saw blade stops within two seconds. However, there may be a delay between the time you release the trigger and when the brake engages. Occasionally the brake may miss completely. If the brake misses frequently, the saw needs servicing by an authorized MILWAUKEE service facility. The brake is not a substitute for the guard, and you must always wait for the blade to stop completely before removing the saw from the workpiece. The correct brush grade must be used for proper operation of the brake. Use only the correct MILWAUKEE replacement brushes when servicing the tool.

Troubleshooting

If the blade does not follow a straight line:

•Teeth are dull. This is caused by hitting a hard object such as a nail or stone, dull- ing teeth on one side. The blade tends to cut to the side with the sharpest teeth.

•Shoe is out of line or bent

•Blade is bent

•Rip fence or guide is not being used

If the blade binds, smokes or turns blue from friction:

•Blade is dull

•Blade is on backwards

•Blade is bent

•Blade is dirty

•Workpiece is not properly supported

•Incorrect blade is being used

APPLICATION | SUGGESTED | |

|

| |

For cuts made at or near | Handle in lower positions (Fig. 16) allows for more leverage | |

waist level |

| when pushing the saw through the workpiece. |

|

| |

For shallow cuts made at | Handle in lower positions allows the user to apply increased | |

or near waist level |

| downward force during shallow cuts. |

|

| |

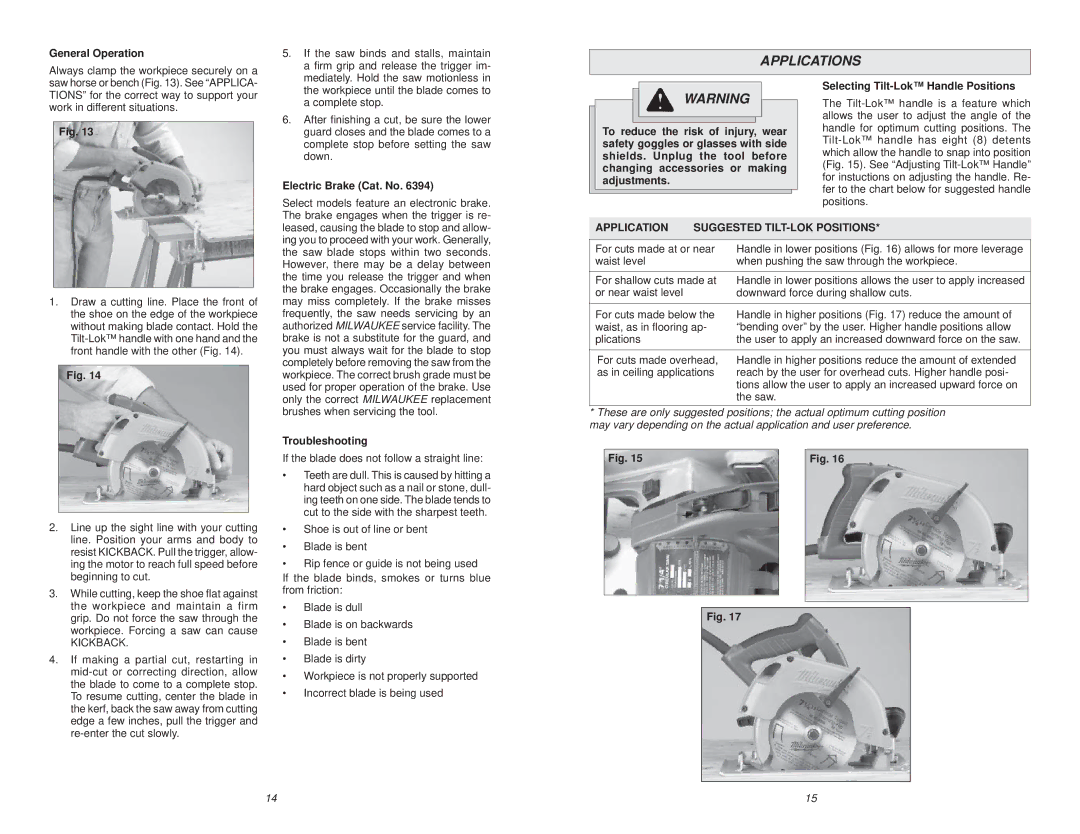

For cuts made below the | Handle in higher positions (Fig. 17) reduce the amount of | |

waist, as in flooring ap- | “bending over” by the user. Higher handle positions allow | |

plications |

| the user to apply an increased downward force on the saw. |

|

| |

For cuts made overhead, | Handle in higher positions reduce the amount of extended | |

as in ceiling applications | reach by the user for overhead cuts. Higher handle posi- | |

|

| tions allow the user to apply an increased upward force on |

|

| the saw. |

*These are only suggested positions; the actual optimum cutting position may vary depending on the actual application and user preference.

Fig. 15 |

| Fig. 16 |

|

|

|

|

|

|

Fig. 17

14 | 15 |