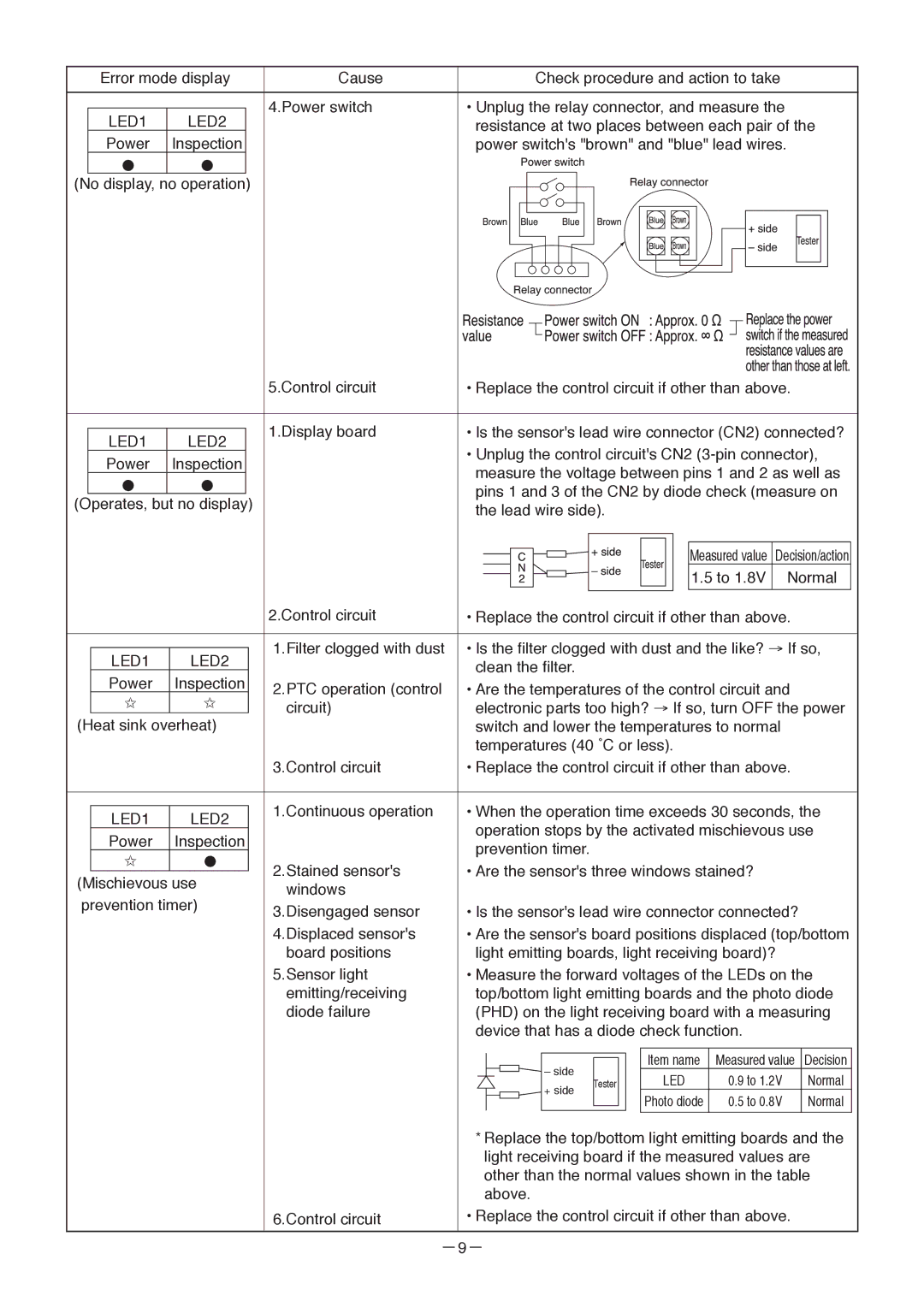

| Error mode display | Cause | Check procedure and action to take | |

|

|

|

|

|

|

|

| 4.Power switch | • Unplug the relay connector, and measure the |

| LED1 | LED2 | ||

|

| resistance at two places between each pair of the | ||

| Power | Inspection |

| |

|

| power switch's "brown" and "blue" lead wires. | ||

| ● | ● |

|

|

(No display, no operation)

|

|

|

| 5.Control circuit | • Replace the control circuit if other than above. |

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

| 1.Display board | • Is the sensor's lead wire connector (CN2) connected? |

| |||||||||

| LED1 | LED2 |

|

| |||||||||||

|

|

| • Unplug the control circuit's CN2 |

| |||||||||||

| Power | Inspection |

|

|

| ||||||||||

|

|

| measure the voltage between pins 1 and 2 as well as |

| |||||||||||

| ● | ● |

|

|

| ||||||||||

|

|

| pins 1 and 3 of the CN2 by diode check (measure on |

| |||||||||||

(Operates, but no display) |

|

| |||||||||||||

| the lead wire side). |

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Measured value | Decision/action |

| ||

|

|

|

| 2.Control circuit |

|

|

|

|

|

| 1.5 to 1.8V | Normal |

| ||

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

| • Replace the control circuit if other than above. |

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

| 1.Filter clogged with dust | • Is the filter clogged with dust and the like? → If so, |

| |||||||||

| LED1 | LED2 |

|

| |||||||||||

|

|

| clean the filter. |

|

|

|

|

|

|

|

| ||||

| Power | Inspection |

| 2.PTC operation (control |

|

|

|

|

|

|

|

| |||

|

| • Are the temperatures of the control circuit and |

|

| |||||||||||

| ✩ | ✩ |

|

|

| ||||||||||

|

| circuit) | electronic parts too high? → If so, turn OFF the power |

| |||||||||||

(Heat sink overheat) |

| switch and lower the temperatures to normal |

|

| |||||||||||

|

|

|

|

| temperatures (40 ˚C or less). |

|

|

|

| ||||||

|

|

|

| 3.Control circuit | • Replace the control circuit if other than above. |

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

| 1.Continuous operation | • When the operation time exceeds 30 seconds, the |

| |||||||||

| LED1 | LED2 |

|

| |||||||||||

|

|

| operation stops by the activated mischievous use |

| |||||||||||

| Power | Inspection |

|

|

| ||||||||||

|

|

| prevention timer. |

|

|

|

|

|

|

|

| ||||

| ✩ | ● |

| 2.Stained sensor's |

|

|

|

|

|

|

|

| |||

|

| • Are the sensor's three windows stained? |

|

|

| ||||||||||

(Mischievous use |

|

|

| ||||||||||||

windows |

|

|

|

|

|

|

|

|

|

|

| ||||

prevention timer) |

|

|

|

|

|

|

|

|

|

|

| ||||

3.Disengaged sensor | • Is the sensor's lead wire connector connected? |

|

| ||||||||||||

|

|

|

|

|

| ||||||||||

|

|

|

| 4.Displaced sensor's | • Are the sensor's board positions displaced (top/bottom |

| |||||||||

|

|

|

| board positions | light emitting boards, light receiving board)? |

|

| ||||||||

|

|

|

| 5.Sensor light | • Measure the forward voltages of the LEDs on the |

| |||||||||

|

|

|

| emitting/receiving | top/bottom light emitting boards and the photo diode |

| |||||||||

|

|

|

| diode failure | (PHD) on the light receiving board with a measuring |

| |||||||||

|

|

|

|

| device that has a diode check function. |

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

| – side |

|

| Item name | Measured value | Decision |

| ||

|

|

|

|

|

|

| Tester | LED | 0.9 to 1.2V | Normal |

| ||||

|

|

|

|

|

|

| + side |

| |||||||

|

|

|

|

|

|

|

|

| Photo diode | 0.5 to 0.8V | Normal |

| |||

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| * Replace the top/bottom light emitting boards and the |

| light receiving board if the measured values are |

| other than the normal values shown in the table |

| above. |

6.Control circuit | • Replace the control circuit if other than above. |

|

|

|