19.

BELT TENSION ADJUSTMENTTine

Clutch

Periodic adjustment of the belt tension may be re- quired due to normal stretch and wear on the belt. Adjustment is needed if the tines seem to hesitate

while tilling, but the engine maintains the samespeed.

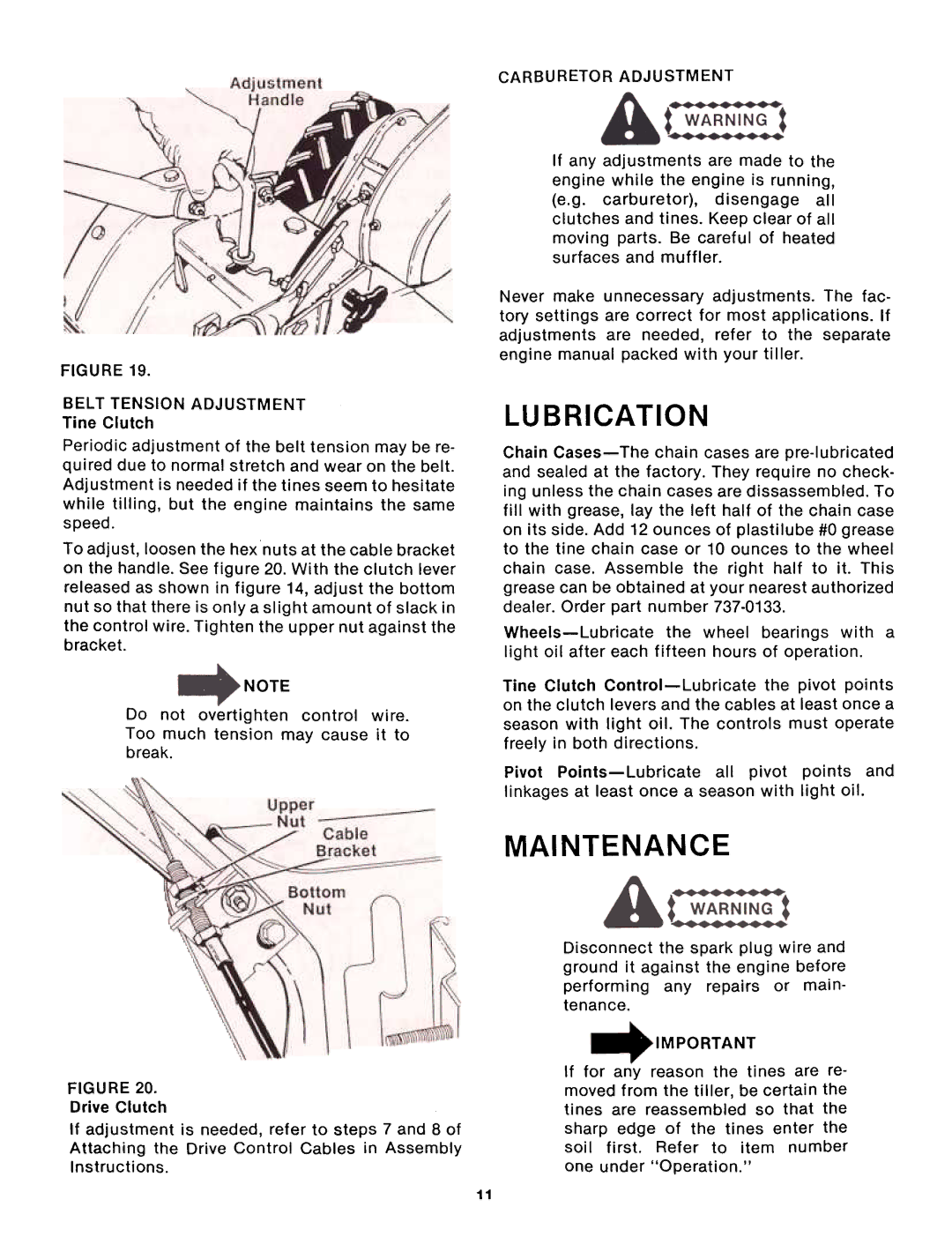

To adjust, loosen the hex nuts at the cable bracket on the handle. See figure 20. With the clutch lever released as shown in figure 14, adjust the bottom nut so that there is only a slight amount of slack in the control wire. Tighten the upper nut against the bracket.

CARBURETOR ADJUSTMENT

If any adjustments are made to theengine while the engine is running,(e.g.

carburetor), disengage all clutches and tines. Keep clear of all moving parts. Be careful of heated surfaces and muffler.

Never make unnecessary adjustments. The fac-

tory settings are correct for most applications. If

adjustments are needed, refer to the separate engine manual packed with your tiller.

Chain

ing unless the chain cases are dissassembled. To fill with grease, lay the left half of the chain case on its side. Add 12 ounces of plastilube #0 grease to the tine chain case or 10 ounces to the wheel chain case. Assemble the right half to it. This grease can be obtained at your nearest authorizeddealer.

Order part number

NOTE

Do not overtighten control wire.Too much tension may cause it tobreak.

Clutch

Pivot

MAl NTENANCE

FIGURE 20.

Drive Clutch

If adjustment is needed, refer to steps 7 and 8 of Attaching the Drive Control Cables in Assembly Instructions.

Disconnect the spark plug wire and ground it against the engine before

performing any repairs or

IMPORTANT

If for any reason the tines are re- moved from the tiller, be certain the tines are reassembled so that the sharp edge of the tines enter the soil first. Refer to item number one under "Operation."