Section

2Assembly

WARNING

To prevent personal injury or property damage, do not start the engine until all assembly steps are complete and you

4. The tiller is heavy. You should not attempt to remove it from the shipping platform until instructed to do so in these “Assembly” steps.

1 2 3 4

56

have read and understand the safety and

HARDWARE BAG PARTS LIST

7

89

operating instructions in this Manual.

Fig. |

|

Ref. Qty. | Description |

11

10

INTRODUCTION

Carefully follow these assembly steps to correctly prepare your tiller for use. It is recommended that you read this Section in its entirety before beginning assembly.

INSPECT UNIT

Inspect the unit and carton for damage immediately after delivery. Contact the carrier (trucking company) if you find or suspect damage. Inform them of the damage and request instructions for filing a claim. To protect your rights, put your claim in writing and mail a copy to the carrier within 15 days after the unit has been delivered. Contact us at the factory if you need assistance in this matter.

UNPACKING AND ASSEMBLY INSTRUCTIONS

STEP 1: UNPACKING INSTRUCTIONS

1.Remove any cardboard inserts and packaging material from the carton. Remove any staples from the bottom of the carton and remove the carton.

2.Cut the large, plastic tie strap that secures the transmission tube to the ship- ping pallet. Leave the handlebars on top of the tiller to avoid damaging any cables.

3. A bag with loose hardware is inside the literature envelope. Check the contents against the following list and Figure

NOTE: For electric start units, a second hardware bag is located near the battery.

6

12

21 Keyed Washer

31 Wheel Gear Lever Knob

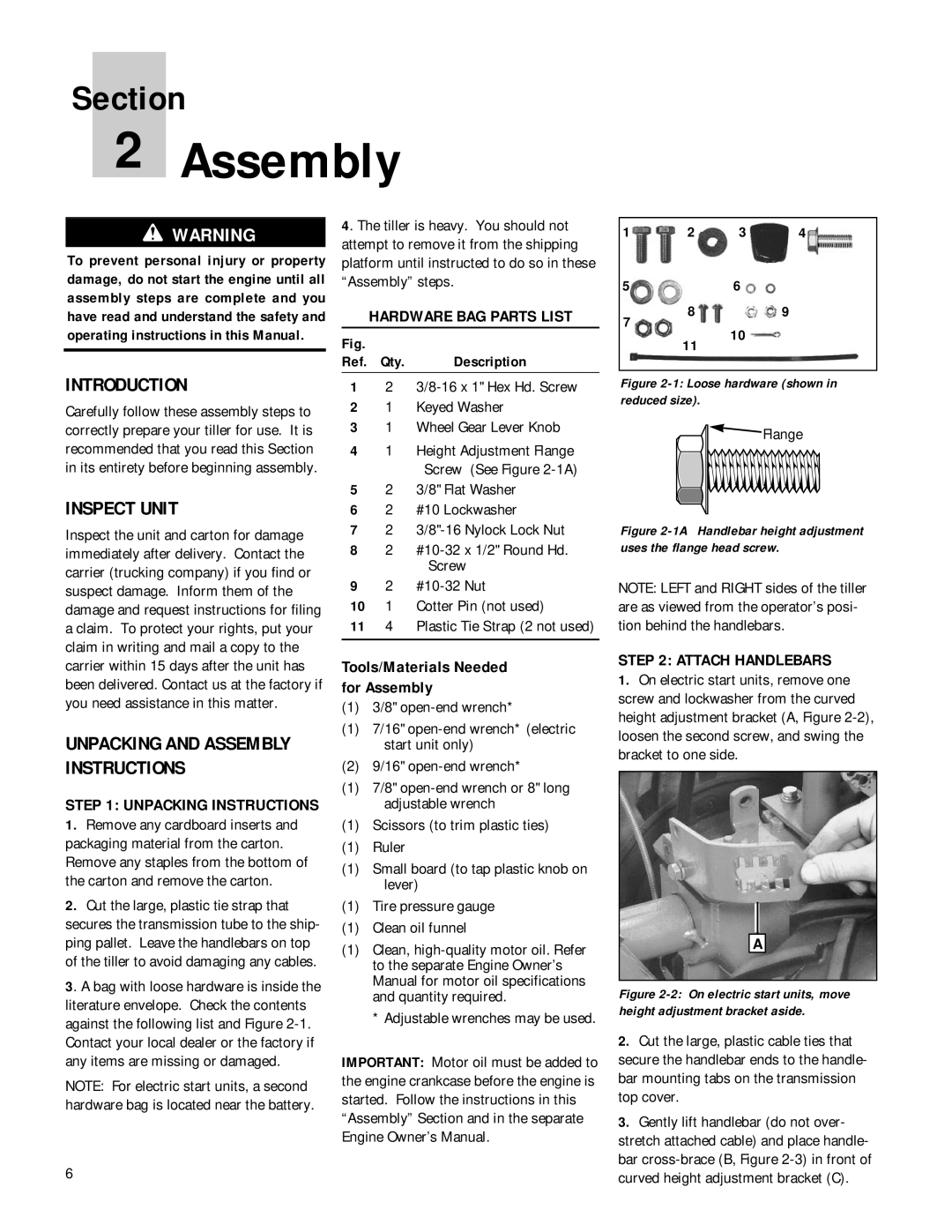

41 Height Adjustment Flange Screw (See Figure

52 3/8" Flat Washer

62 #10 Lockwasher

72

82

92

101 Cotter Pin (not used)

114 Plastic Tie Strap (2 not used)

Tools/Materials Needed for Assembly

(1) 3/8"

(1)7/16"

(2)9/16"

(1)7/8"

(1) Scissors (to trim plastic ties)

(1) Ruler

(1)Small board (to tap plastic knob on lever)

(1) Tire pressure gauge

(1) Clean oil funnel

(1)Clean,

*Adjustable wrenches may be used.

IMPORTANT: Motor oil must be added to the engine crankcase before the engine is started. Follow the instructions in this “Assembly” Section and in the separate Engine Owner’s Manual.

Figure 2-1: Loose hardware (shown in reduced size).

![]() Flange

Flange

Figure 2-1A Handlebar height adjustment uses the flange head screw.

NOTE: LEFT and RIGHT sides of the tiller are as viewed from the operator’s posi- tion behind the handlebars.

STEP 2: ATTACH HANDLEBARS

1.On electric start units, remove one screw and lockwasher from the curved height adjustment bracket (A, Figure

A

Figure 2-2: On electric start units, move height adjustment bracket aside.

2.Cut the large, plastic cable ties that secure the handlebar ends to the handle- bar mounting tabs on the transmission top cover.

3.Gently lift handlebar (do not over- stretch attached cable) and place handle- bar