FS3SP CONCRETE SAW — INSPECTION -BLADE PLACEMENT

NOTE

The following steps should be accomplished before placing the diamond blade on the

blade shaft.

■Place the console ON/OFF button in the OFF position.

■Raise the saw to a high position by cranking the Raise/Lower handle in a counterclockwise direction.

■Use the Blade Nut Wrench & Blade Shaft Locking Wrench stored in the lower section of the console to install the diamond blade.

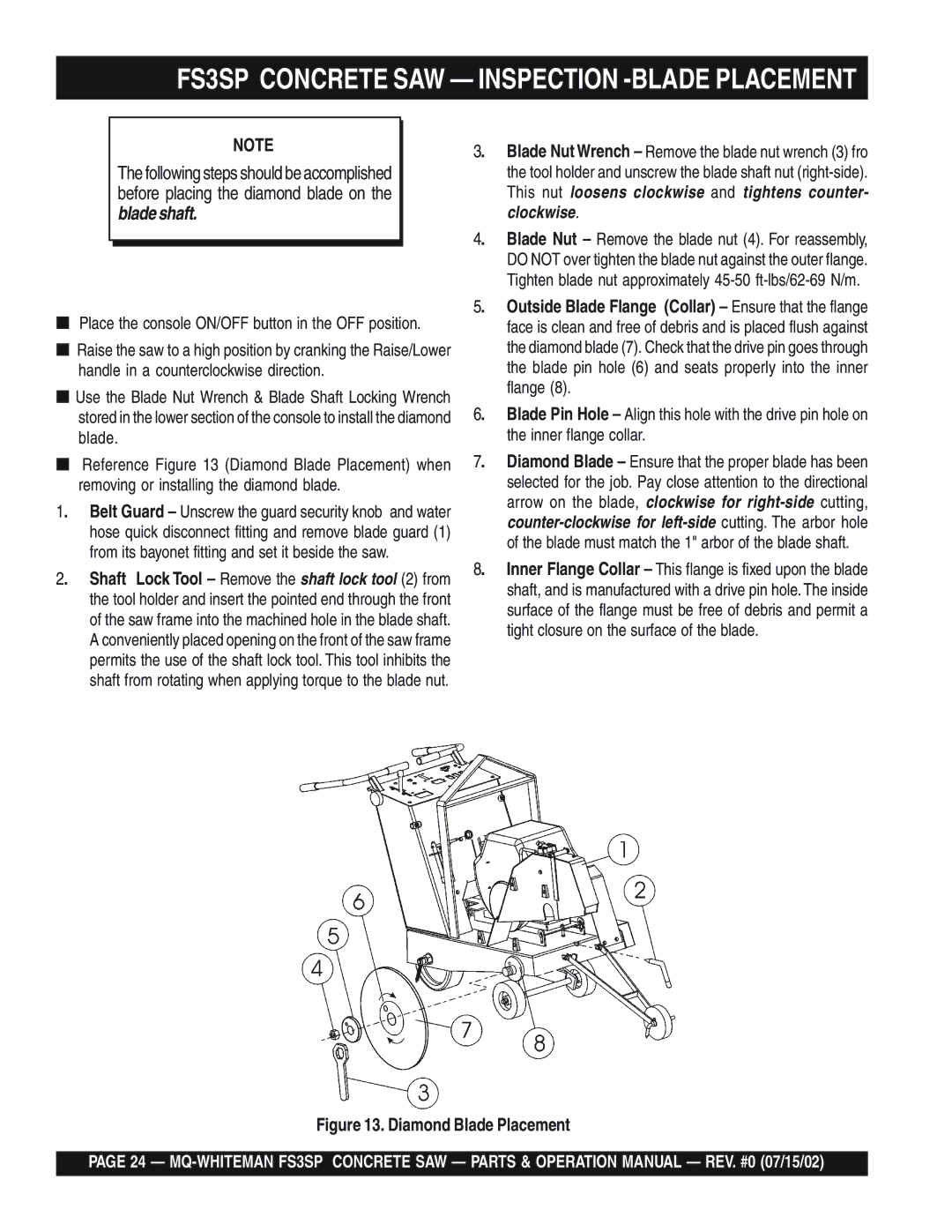

■Reference Figure 13 (Diamond Blade Placement) when removing or installing the diamond blade.

1. Belt Guard – Unscrew the guard security knob and water hose quick disconnect fitting and remove blade guard (1) from its bayonet fitting and set it beside the saw.

2. Shaft Lock Tool – Remove the shaft lock tool (2) from the tool holder and insert the pointed end through the front of the saw frame into the machined hole in the blade shaft. A conveniently placed opening on the front of the saw frame permits the use of the shaft lock tool. This tool inhibits the shaft from rotating when applying torque to the blade nut.

3. Blade Nut Wrench – Remove the blade nut wrench (3) fro the tool holder and unscrew the blade shaft nut

4. Blade Nut – Remove the blade nut (4). For reassembly, DO NOT over tighten the blade nut against the outer flange. Tighten blade nut approximately

5. Outside Blade Flange (Collar) – Ensure that the flange face is clean and free of debris and is placed flush against the diamond blade (7). Check that the drive pin goes through the blade pin hole (6) and seats properly into the inner flange (8).

6. Blade Pin Hole – Align this hole with the drive pin hole on the inner flange collar.

7. Diamond Blade – Ensure that the proper blade has been selected for the job. Pay close attention to the directional arrow on the blade, clockwise for

8. Inner Flange Collar – This flange is fixed upon the blade shaft, and is manufactured with a drive pin hole. The inside surface of the flange must be free of debris and permit a tight closure on the surface of the blade.

Figure 13. Diamond Blade Placement

PAGE 24 —