MVC98D2 specifications

The Multiquip MVC98D2 is a robust and versatile diesel-powered compactor designed for optimal performance in compacting soil and asphalt in various construction applications. Built with durability in mind, the MVC98D2 is a favored choice among contractors looking for reliable equipment that can withstand the rigors of job sites.One of the standout features of the MVC98D2 is its advanced vibratory system. This compactor uses a unique dual eccentric weight system, which creates uniform vibration across the entire plate surface. This technology enhances compaction efficiency, allowing operators to achieve maximum density with fewer passes, thus saving time and reducing fuel consumption. The unit's compaction force is complemented by its heavy-duty plate design, which ensures superior performance even in challenging conditions.

Another important characteristic of the MVC98D2 is its powerful and fuel-efficient diesel engine. The model is typically equipped with a dependable engine that provides ample power while minimizing emissions. This makes it not only powerful but also environmentally conscious, adhering to regulatory standards in various regions. The engine is matched with an efficient transmission system that ensures smooth operation and optimal torque delivery.

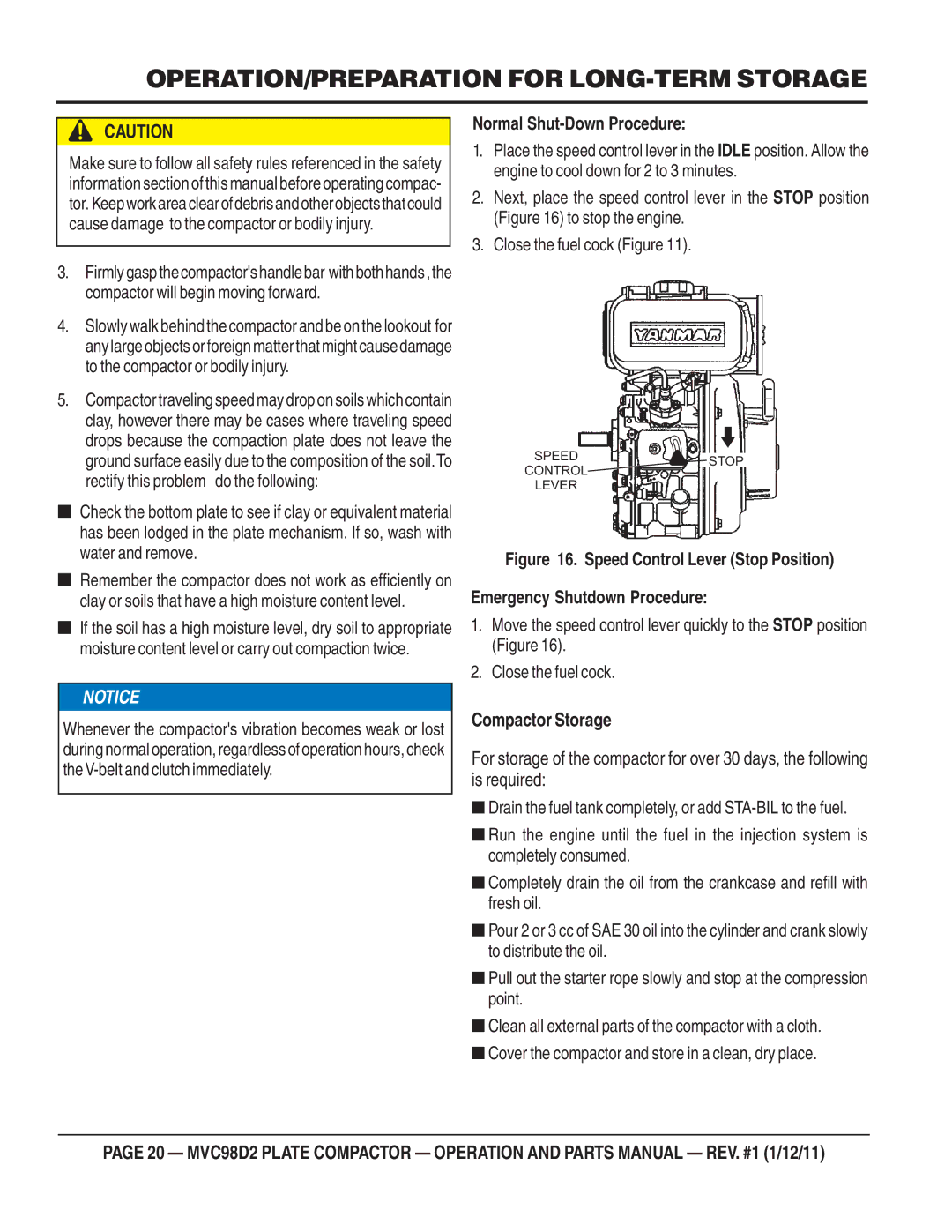

In addition to its performance features, the MVC98D2 boasts a user-friendly design. The machine’s controls are intuitively arranged, allowing operators to easily and quickly familiarize themselves with its operation. The presence of an adjustable handle enhances comfort, improving operator ergonomics and reducing fatigue during extended use. Safety features, such as an emergency stop button, are also incorporated to enhance workplace safety.

The compact size and weight of the MVC98D2 allow for easy transportation and maneuverability on job sites, making it an excellent choice for both large-scale projects and smaller, confined spaces. The unit is designed to handle a variety of applications including backfill, trenching, and asphalt work, contributing to its versatility across numerous construction needs.

Overall, the Multiquip MVC98D2 stands out for its combination of power, efficiency, and user-friendly features. With its innovative technologies and robust design, it is engineered to deliver superior performance in the toughest conditions, making it a reliable tool for professionals in the construction industry.