Model TLW-300SS WELDER/AC Generator

Diesel engine exhaust and some

Proposition 65WARNING

Page

Table of Contents

Ordering parts has never been easier

Parts Ordering Procedures

Rules for Safe Operation

General Safety

Rules for Safe Operation

Machine Safety Decals

Operation and Safety Decals

Operation and Safety Decals

TLW-300SS Specifications

TLW-300SS General Information

TLW-300SS Dimensions

TLW-300SS Dimensions

Explanation of Chart

TLW-300SS -TRAILER-SAFETY Guidelines

TRLR-10W

TLW-300SS TRAILER-SPECIFICATIONS

TLW-300SS TRAILER-SPECIFICATIONS

Suspension

Tires/Wheels/Lug Nuts

Tire Wear/Inflation

Lug NutTorque Requirements

TLW-300SS -TRAILER Safety Guidelines

Torque Ft.-Lbs

TLW-300SS -TRAILER-WIRING Diagram

TLW-300SS -TOWING

Towing Safety Precautions

TLW-300SS Controls and Indicators

TLW-300SS Controls and Indicators

Volt Receptacle

TLW-300SS Outputterminal Overview

Outdoor Installation

TLW-300SS Installation

General Inspection Prior to Operation

TLW-300SS PRE-SETUP

Recommended Motor Oil

Air Cleaner

Cleaning the Radiator

Battery

Fan Belt Tension

TLW-300SS Instrumentation

TLW-300SS Load Application

Single Phase Load

Welding Cables and Polarities

TLW-300SS-WELDER Operating Instructions

Duty Cycle

TLW-300SS-WELDER Operating Instructions

Shutdown

Starting

Cleaning the Fuel Strainer

TLW-300SS Maintenance

General Inspection

Engine Side

TLW-300SS Maintenance

TLW-300SS -GEN. Wiring Diagram S/N 5308736 and below

TLW-300SS -GEN. Wiring Diagram S/N 5308737 and Above

TLW-300SS -ENGINE Wiring Diagram S/N 5308736 and below

TLW-300SS -ENGINE Wiring Diagram S/N 5308737 and Above

TLW-300SS -TROUBLESHOOTING Engine

TLW-300SS -TROUBLESHOOTING Engine

Engine Troubleshooting Part

TLW-300SS -TROUBLESHOOTING Engine

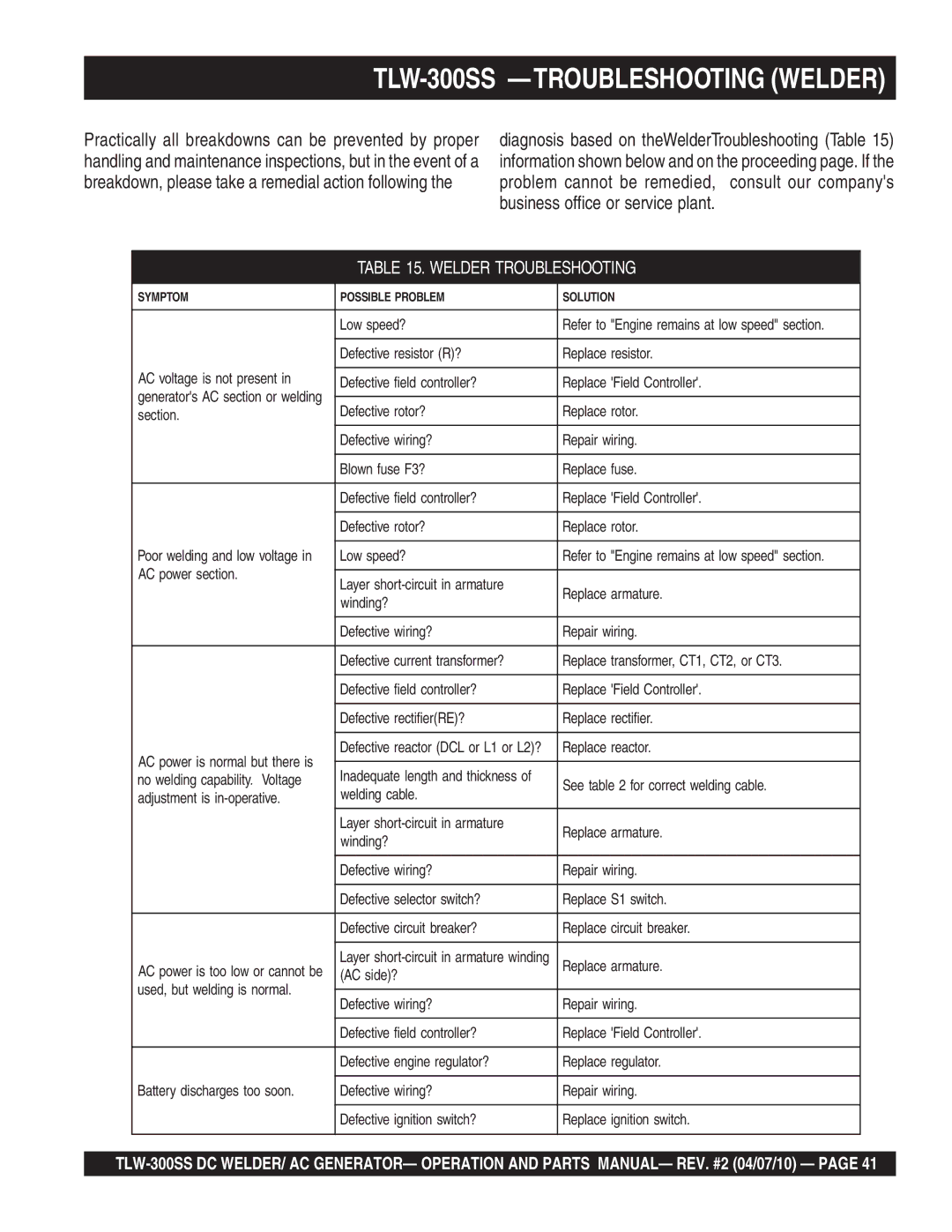

Welder Troubleshooting

TLW-300SS -TROUBLESHOOTING Welder

Xxxxx only Not Used on

Explanation of Code in Remarks Column

Qty Description

TLW-300S Suggested Spare Parts

Generator Assy

TLW-300SS Generator Assy

QTY Remarks

Control BOX Assy

TLW-300SS Control BOX Assy

SET Screw

Machine Screw

HEX. NUT

Lock Washer

TLW-300SS Control BOX Assy

Rubber Sheet

COVER, Output Terminal

Collar

Rubber Washer

Control Parts ASSY. Part

TLW-300SS -CONTROL Parts ASSY. Part

COVER, Electric Parts

FB6PS

RA30YN20SB 3KOHM

SET BOARD, Shunt

TLW-300SS -CONTROL Parts ASSY. Part

DC Reactor

BRACKET, AVR

Reactor Bracket

Armature Solenoid

Engine and Radiator Assy

TLW-300SS Engine and Radiator Assy

Rubber Mount

Battery Assy

TLW-300SS -BATTERY Assy

Battery Band

Battery Sheet

Battery Bolt

Wing NUT

Muffler Assy

TLW-300SS -MUFFLER Assy

Elbow JOINT, 1 1/4

Exhaust Pipe

Gasket

Fuel Tank Assy

TLW-300SS -FUELTANK Assy

Fuel Filter

CAP, Fuel Tank

BRACKET, Fuel Tank

Drain Joint

Enclosure Assy

TLW-300SS -ENCLOSURE Assy

Floor Panel

Lining

Panel

Duct

TLW-300SS Enclosure Assy

DOOR, Rear Frame

COVER, Rear Frame

Side Door

Door Handle

Rubber Seal Assy

TLW-300SS -RUBBER Seal Assy

0229200630

Decal Assy

TLW-300SS -DECALS

Calsonic

STCL78YUASA

Crankcase Assy

Kubota D722EB -CRANKCASE Assy

CAP, Sealing

OIL Switch

PIN, Straight

PIN, Pipe

OIL PAN Assy

Kubota D722EB -OIL PAN Assy

GASKET, OIL PAN

COMP. OIL PAN

Cylinder Head Assy

Kubota D722EB -CYLINDER Head Assy

Sealing CAP

Engine Hook

Inlet Valve Guide

Cylinder Head Bolt

Gear Case Assy

Kubota D722EB -GEAR Case Assy

Pipe Joint

Start Spring PIN

Spring

Valve Seat

AIR Cleaner Assy

Kubota D722EB -AIR Cleaner Assy

AIR Cleaner Cover

AIR Cleaner Body

AIR Cleaner Label

AIR Cleaner Band

Inlet Manifold Assy

Kubota D722EB -INLET Manifold Assy

Water Return Pipe

Exhaust Manifold Assy

Kubota D722EB -EXHAUST Manifold Assy

UBS NUT

Exhaust Manifold

UBS Bolt

Valve and Rocker ARM Assy

Kubota D722EB -VALVE and Rocker ARM Assy

Inlet Valve

Adjusting Screw

Exhaust Valve

Valve Spring

Head Cover Assy

Kubota D722EB -HEAD Cover Assy

Breather Gasket

COMP. Breather

Breather Element

Plate

Dipstick Assy

Kubota D722EB -DIPSTICK Assy

OIL Gauge

Main Bearing Case Assy

Kubota D722EB---MAIN Bearing Case Assy

Bearing Case Bolt

Kubota D722EB -MAIN Bearing Case Assy

Bearing Case Gasket

Bearing Case Cover

Camshaft Assy

Kubota D722EB -CAMSHAFT Assy

Push ROD

Tappet

CAM Gear

Camshaft Stopper

Piston and Crankshaft Assy

Kubota D722EB -PISTON and Crankshaft Assy

STD

Connecting ROD Bolt

Piston Ring

Piston PIN Bushing

Flywheel Assy

Kubota D722EB -FLYWHEEL Assy

Ring Gear

Flywheel Housing

Fuel Camshaft Assy

Kubota D722EB -FUEL Camshaft Assy

Ball Bearing

Fuel Camshaft

Injection Pump Gear

Governor Sleeve

Nozzle Holder COMP. Assy

Kubota D722EB -NOZZLE Holder COMP. Assy

Inlcudes Items W

Adjusting Washer

Nozzle Spring

Spacer

Kubota D722EB -NOZZLE Holder COMP. Assy

1584198770

Nozzle Holder Glow Plug Assy

Kubota D722EB ---NOZZLE Holder Glow Plug Assy

Heat Seal

Kubota D722EB -NOZZLE Holder Glow Plug Assy

Injection Pipe

Pipe Clamp

Injection Pump Assy

Kubota D722EB -INJECTION Pump Assy

EYE Joint

Injection Pump COMP. Assy

Kubota D722EB -INJECTION Pump COMP. Assy

Delivery Valve

Pump Plunger

Deliver Valve Spring

Sleeve Flange

Fuel Filter Assy

Kubota D722EB -FUEL Filter Assy

Lever O Ring

Cock Lever

Filter CUP

Fuel Label

Fuel Pump Assy

Kubota D722EB -FUEL Pump Assy

Fuel Pump Gasket

Adjusting Bolt

CAP

Pipe

Governor Assy

Kubota D722EB -GOVERNOR Assy

Governor Spring

Start Spring

Fork Lever Comp

Fork Lever

Speed Control Plate Assy

Kubota D722EB -SPEED Control Plate Assy

Kubota D722EB-SPEED Control Plate Assy

Stop Solenoid Assy

Kubota D722EB -STOP Solenoid Assy

Flange Bolt

Stop Solenoid

Starter Assy

Kubota D722EB -STARTER Assy

010 1523163015

Starter Component Assy

Kubota D722EB -STARTER Component Assy

Yoke

Housing Assy

Armature

Over Running Clutch

Dynamo Assy

Kubota D722EB -DYNAMO Assy

FAN Drive Pulley

Dynamo Stay

FAN

FAN Collar

Water Flange Assy

Kubota D722EB -WATER Flange Assy

Thermostat Cover

Thermometer Switch

Thermostat Assy

Water Pump Assy

Kubota D722EB -WATER Pump Assy

Bearing

Water Pump Flange

Water Pump Impeller

FAN Pulley

Water Pipe Assy

Kubota D722EB -WATER Pipe Assy

Hose Clamp

Water Pipe

Starter Switch Assy

Kubota D722EB -STARTER Switch Assy

Starter KEY

Glow Lamp Timer

Piston KIT and Accessories Assy

Kubota D722EB -PISTON KIT and Accessories Assy

GASKET, Muffler

Piston

Piston Ring Assy

Freight Policy

Terms and Conditions of Sale Parts

Page

HERE’S HOW to GET Help