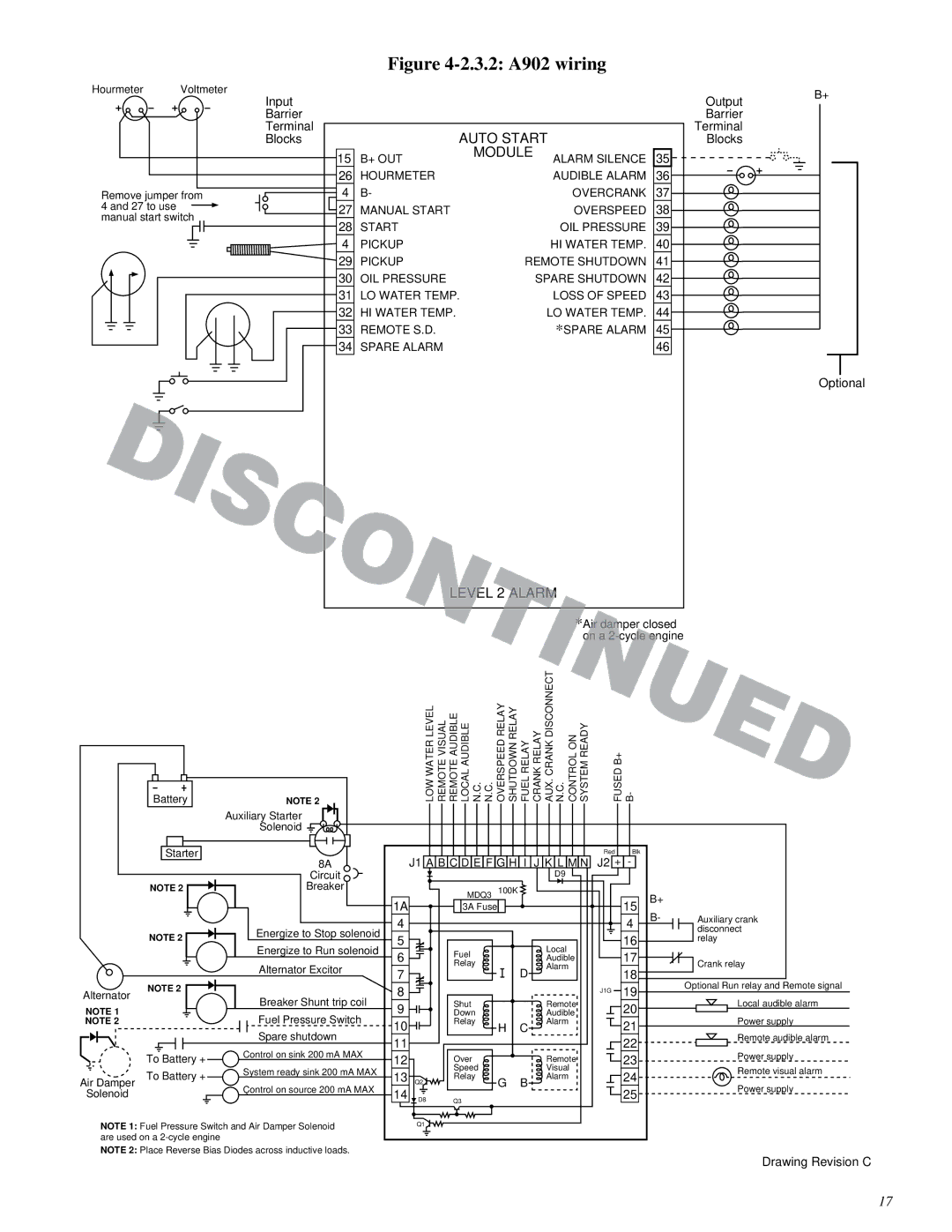

Figure 4-2.3.2: A902 wiring

Hourmeter Voltmeter

Input

Barrier

Terminal

Blocks

Remove jumper from 4 and 27 to use ![]() manual start switch

manual start switch

| AUTO START |

| |||

|

| MODULE |

|

| |

15 | B+ OUT | ALARM SILENCE | 35 | ||

| |||||

26 | HOURMETER |

| AUDIBLE ALARM | 36 | |

4 | B- |

| OVERCRANK | 37 | |

27 | MANUAL START |

| OVERSPEED | 38 | |

28 | START |

| OIL PRESSURE | 39 | |

4 | PICKUP |

| HI WATER TEMP. | 40 | |

29 | PICKUP | REMOTE SHUTDOWN | 41 | ||

30 | OIL PRESSURE |

| SPARE SHUTDOWN | 42 | |

31 | LO WATER TEMP. |

| LOSS OF SPEED | 43 | |

32 | HI WATER TEMP. |

| LO WATER TEMP. | 44 | |

33 | REMOTE S.D. |

| *SPARE ALARM | 45 | |

34 | SPARE ALARM |

|

| 46 | |

LEVEL 2 ALARM

*Air damper closed on a

Output

Barrier

Terminal

Blocks

B+

Optional

|

|

|

|

|

|

|

| Battery | NOTE 2 | ||||

|

|

|

|

|

| Auxiliary Starter |

|

|

|

|

|

| Solenoid |

LOW WATER LEVEL REMOTE VISUAL REMOTE AUDIBLE LOCAL AUDIBLE N.C. N.C. OVERSPEED RELAY SHUTDOWN RELAY FUEL RELAY CRANK RELAY AUX. CRANK DISCONNECT N.C. CONTROL ON SYSTEM READY | FUSED B+ B- |

Alternator

NOTE 1

NOTE 2

Starter

NOTE 2 ![]()

![]()

NOTE 2

NOTE 2

8A

Circuit

Breaker

Energize to Stop solenoid

Energize to Run solenoid

Alternator Excitor

Breaker Shunt trip coil

Fuel Pressure Switch

Spare shutdown

|

|

| Red | Blk | |

| J1 A B C D E F G H I J K L M N J2 + - | ||||

|

|

| D9 |

| |

1A | MDQ3 | 100K |

| 15 | |

3A Fuse |

|

| |||

4 |

|

|

| 4 | |

5 |

|

| Local | 16 | |

6 | Fuel |

| 17 | ||

| Audible | ||||

Relay |

| ||||

7 | I | Alarm | 18 | ||

| |||||

| D | ||||

8 |

|

| J1G | 19 | |

9 | Shut |

| Remote | 20 | |

Down |

| Audible | |||

10 | Relay | H | Alarm | 21 | |

| C | ||||

11 |

|

|

| 22 | |

B+ |

|

B- | Auxiliary crank |

| disconnect |

| relay |

| Crank relay |

Optional Run relay and Remote signal

Local audible alarm

Power supply

Remote audible alarm

Air Damper

Solenoid

To Battery +

To Battery +

Control on sink 200 mA MAX

System ready sink 200 mA MAX

Ç ontrol on source 200 mA MAX

12 |

| Over | Remote | 23 |

13 |

| Speed | Visual | 24 |

Q2 | Relay | Alarm | ||

14 |

| G | B | 25 |

D8 | Q3 |

|

Power supply

Remote visual alarm Power supply

NOTE 1: Fuel Pressure Switch and Air Damper Solenoid are used on a

NOTE 2: Place Reverse Bias Diodes across inductive loads.

Q1

Drawing Revision C

17