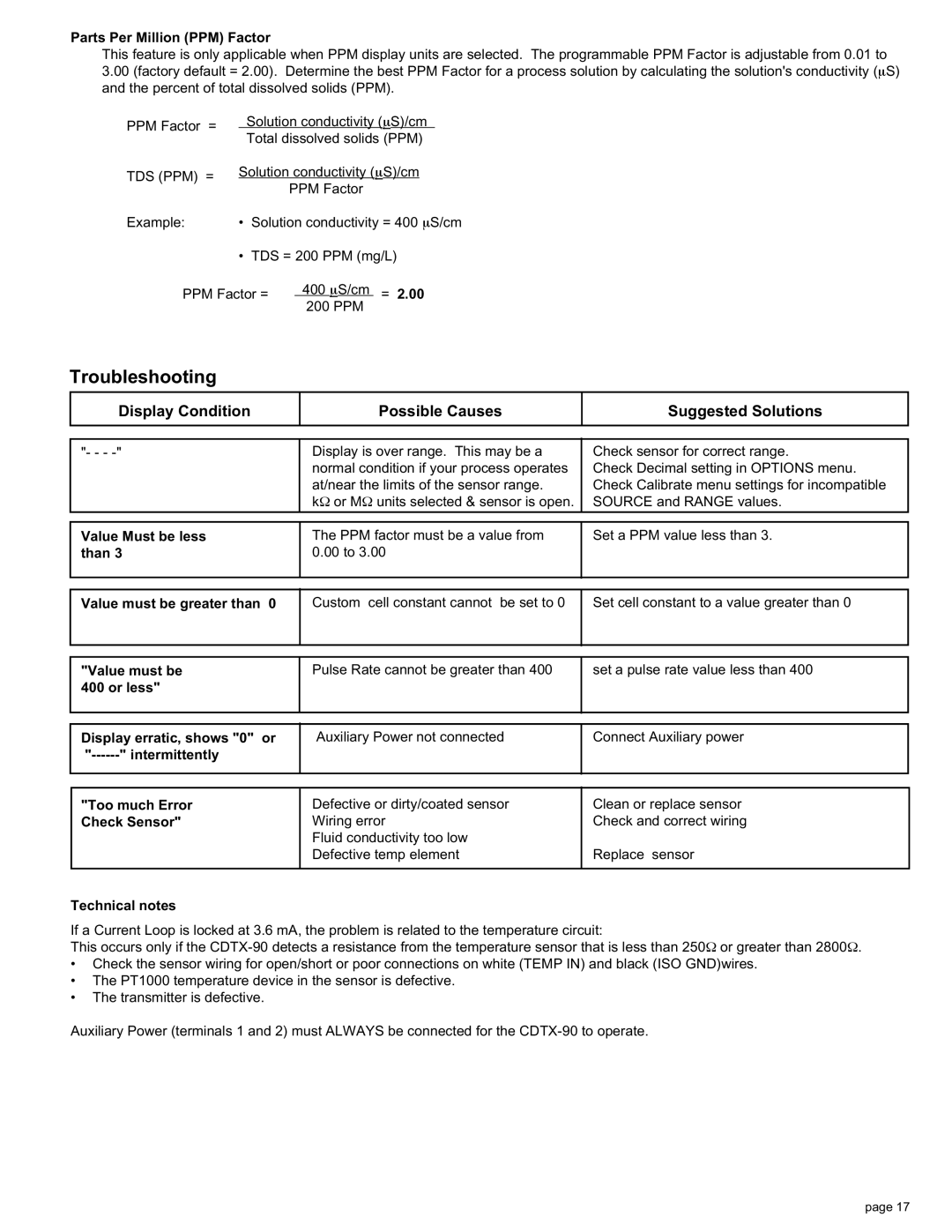

Parts Per Million (PPM) Factor

This feature is only applicable when PPM display units are selected. The programmable PPM Factor is adjustable from 0.01 to

3.00(factory default = 2.00). Determine the best PPM Factor for a process solution by calculating the solution's conductivity (∝S) and the percent of total dissolved solids (PPM).

PPM Factor = | Solution conductivity (∝S)/cm | ||

Total dissolved solids (PPM) | |||

| |||

TDS (PPM) = | Solution conductivity (∝S)/cm | ||

| PPM Factor | ||

|

| ||

Example: | • Solution conductivity = 400 ∝S/cm | ||

| • TDS = 200 PPM (mg/L) | ||

PPM Factor = | 400 ∝S/cm = 2.00 | ||

|

| 200 PPM | |

Troubleshooting

Display Condition | Possible Causes | Suggested Solutions |

|

|

|

|

|

|

"- - - | Display is over range. This may be a | Check sensor for correct range. |

| normal condition if your process operates | Check Decimal setting in OPTIONS menu. |

| at/near the limits of the sensor range. | Check Calibrate menu settings for incompatible |

| kΩ or MΩ units selected & sensor is open. | SOURCE and RANGE values. |

|

|

|

|

|

|

Value Must be less | The PPM factor must be a value from | Set a PPM value less than 3. |

than 3 | 0.00 to 3.00 |

|

|

|

|

|

|

|

Value must be greater than 0 | Custom cell constant cannot be set to 0 | Set cell constant to a value greater than 0 |

|

|

|

|

|

|

"Value must be | Pulse Rate cannot be greater than 400 | set a pulse rate value less than 400 |

400 or less" |

|

|

|

|

|

|

|

|

Display erratic, shows "0" or | Auxiliary Power not connected | Connect Auxiliary power |

|

| |

|

|

|

|

|

|

"Too much Error | Defective or dirty/coated sensor | Clean or replace sensor |

Check Sensor" | Wiring error | Check and correct wiring |

| Fluid conductivity too low |

|

| Defective temp element | Replace sensor |

|

|

|

Technical notes

If a Current Loop is locked at 3.6 mA, the problem is related to the temperature circuit:

This occurs only if the

•Check the sensor wiring for open/short or poor connections on white (TEMP IN) and black (ISO GND)wires.

•The PT1000 temperature device in the sensor is defective.

•The transmitter is defective.

Auxiliary Power (terminals 1 and 2) must ALWAYS be connected for the

page 17