FLR Flow Transmitter

Installation & Programming Instructions

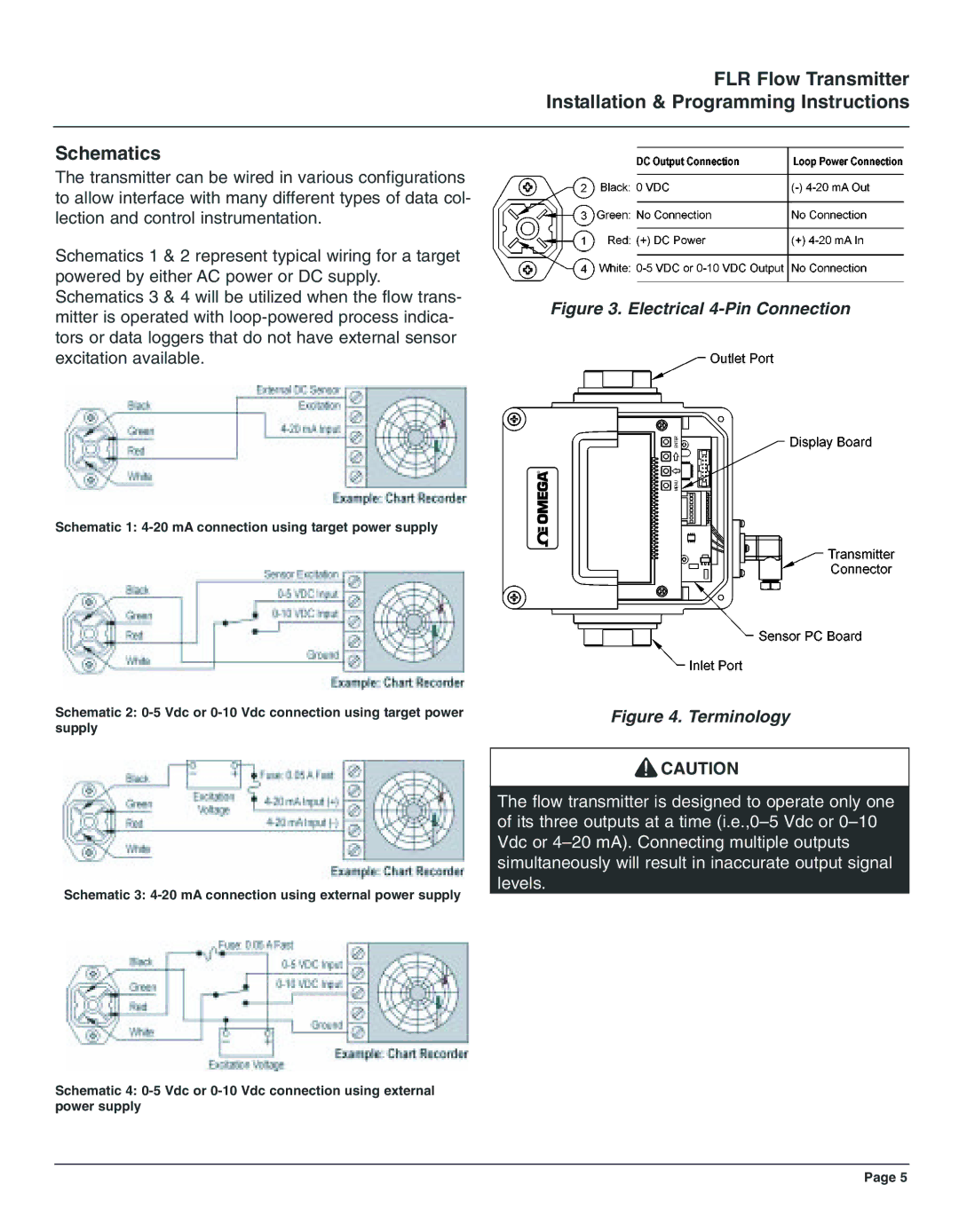

Schematics

The transmitter can be wired in various configurations to allow interface with many different types of data col- lection and control instrumentation.

Schematics 1 & 2 represent typical wiring for a target powered by either AC power or DC supply.

Schematics 3 & 4 will be utilized when the flow trans-

mitter is operated with

excitation available.

Schematic 1:

Schematic 2:

Schematic 3:

Schematic 4:

®

Figure 4. Terminology

![]() CAUTION

CAUTION

The flow transmitter is designed to operate only one of its three outputs at a time

Page 5