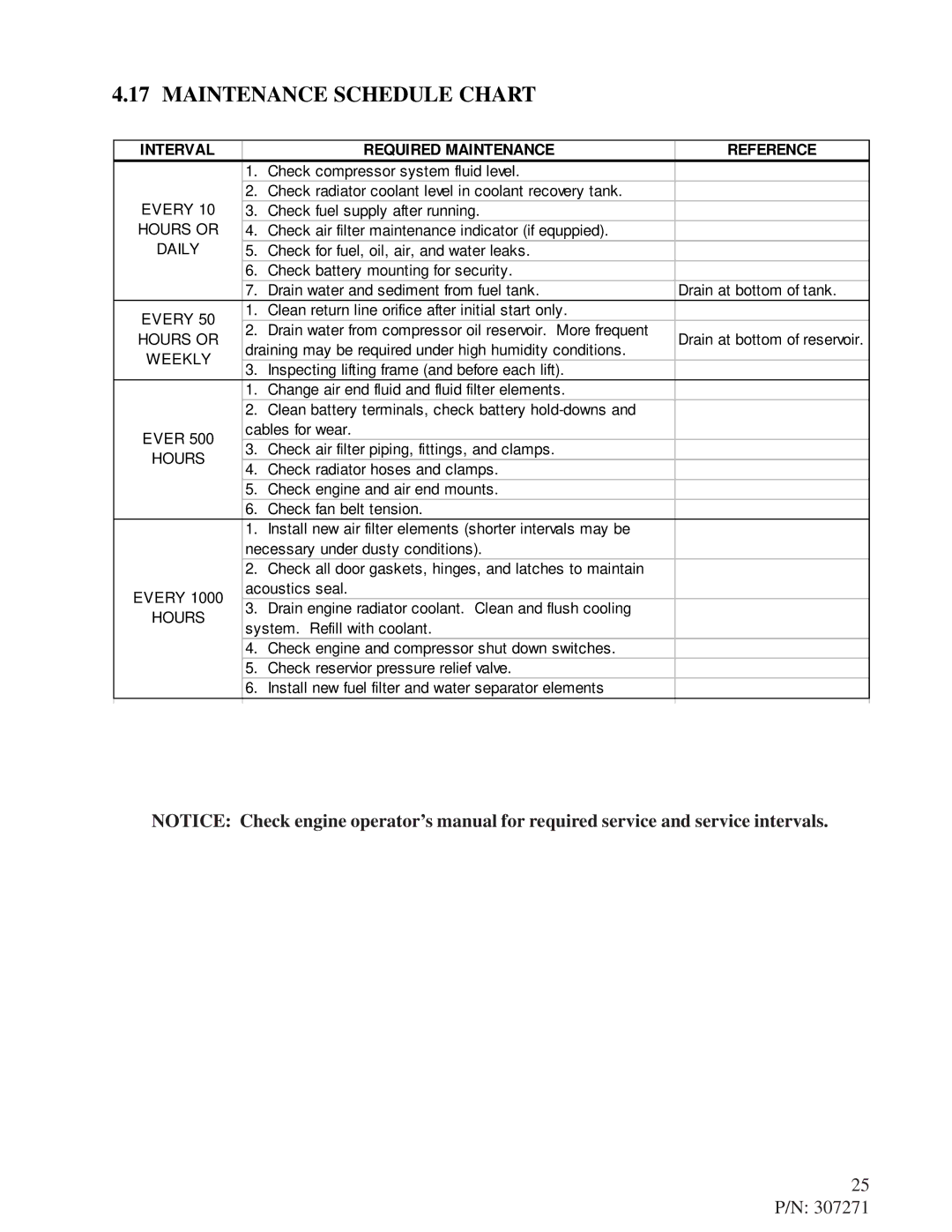

4.17 MAINTENANCE SCHEDULE CHART

INTERVAL |

| REQUIRED MAINTENANCE | REFERENCE | |

| 1. | Check compressor system fluid level. |

| |

EVERY 10 | 2. | Check radiator coolant level in coolant recovery tank. |

| |

3. Check fuel supply after running. |

| |||

HOURS OR | 4. | Check air filter maintenance indicator (if equppied). |

| |

DAILY | 5. | Check for fuel, oil, air, and water leaks. |

| |

| 6. | Check battery mounting for security. |

| |

| 7. | Drain water and sediment from fuel tank. | Drain at bottom of tank. | |

EVERY 50 | 1. | Clean return line orifice after initial start only. |

| |

2. | Drain water from compressor oil reservoir. More frequent | Drain at bottom of reservoir. | ||

HOURS OR | ||||

draining may be required under high humidity conditions. | ||||

WEEKLY |

| |||

3. | Inspecting lifting frame (and before each lift). |

| ||

|

| |||

| 1. | Change air end fluid and fluid filter elements. |

| |

| 2. | Clean battery terminals, check battery |

| |

EVER 500 | cables for wear. |

| ||

3. | Check air filter piping, fittings, and clamps. |

| ||

HOURS |

| |||

4. | Check radiator hoses and clamps. |

| ||

|

| |||

| 5. | Check engine and air end mounts. |

| |

| 6. | Check fan belt tension. |

| |

| 1. | Install new air filter elements (shorter intervals may be |

| |

| necessary under dusty conditions). |

| ||

| 2. | Check all door gaskets, hinges, and latches to maintain |

| |

EVERY 1000 | acoustics seal. |

| ||

3. | Drain engine radiator coolant. Clean and flush cooling |

| ||

HOURS |

| |||

system. Refill with coolant. |

| |||

|

| |||

| 4. | Check engine and compressor shut down switches. |

| |

| 5. | Check reservior pressure relief valve. |

| |

| 6. | Install new fuel filter and water separator elements |

| |

NOTICE: Check engine operator’s manual for required service and service intervals.