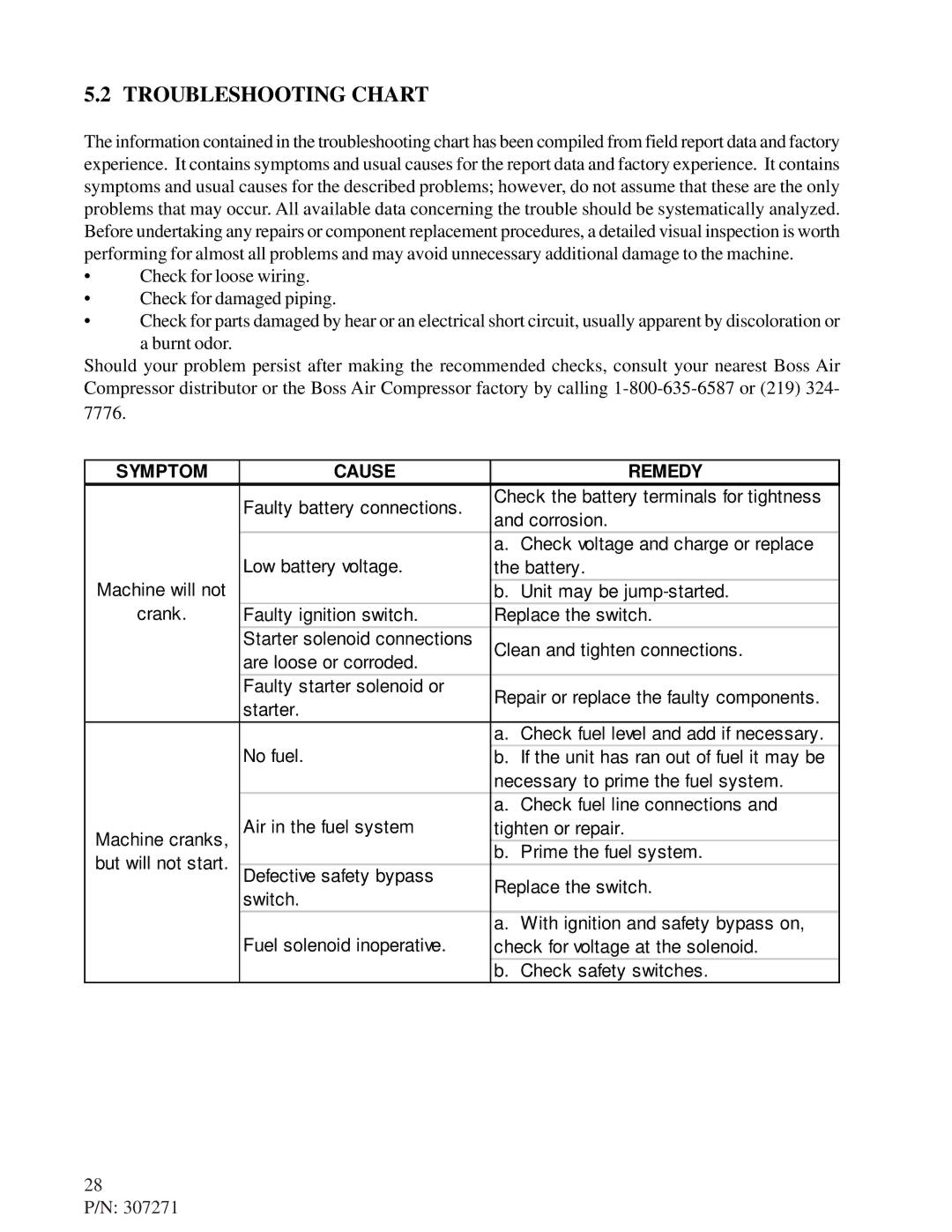

5.2 TROUBLESHOOTING CHART

The information contained in the troubleshooting chart has been compiled from field report data and factory experience. It contains symptoms and usual causes for the report data and factory experience. It contains symptoms and usual causes for the described problems; however, do not assume that these are the only problems that may occur. All available data concerning the trouble should be systematically analyzed. Before undertaking any repairs or component replacement procedures, a detailed visual inspection is worth performing for almost all problems and may avoid unnecessary additional damage to the machine.

•Check for loose wiring.

•Check for damaged piping.

•Check for parts damaged by hear or an electrical short circuit, usually apparent by discoloration or a burnt odor.

Should your problem persist after making the recommended checks, consult your nearest Boss Air Compressor distributor or the Boss Air Compressor factory by calling

SYMPTOM | CAUSE | REMEDY |

| Faulty battery connections. | Check the battery terminals for tightness |

| and corrosion. | |

|

| |

| Low battery voltage. | a. Check voltage and charge or replace |

Machine will not | the battery. | |

| b. Unit may be | |

crank. | Faulty ignition switch. | Replace the switch. |

| Starter solenoid connections | Clean and tighten connections. |

| are loose or corroded. | |

|

| |

| Faulty starter solenoid or | Repair or replace the faulty components. |

| starter. | |

|

| |

| No fuel. | a. Check fuel level and add if necessary. |

| b. If the unit has ran out of fuel it may be | |

|

| necessary to prime the fuel system. |

| Air in the fuel system | a. Check fuel line connections and |

Machine cranks, | tighten or repair. | |

| b. Prime the fuel system. | |

but will not start. |

| |

Defective safety bypass | Replace the switch. | |

| switch. | |

|

| |

| Fuel solenoid inoperative. | a. With ignition and safety bypass on, |

| check for voltage at the solenoid. | |

|

| b. Check safety switches. |

28

P/N: 307271