ST 630P, ST 630P-S, ST 630 specifications

Peerless Industries offers a range of innovative mounting solutions, and the ST 630P-S, ST 630, and ST 630P are standout products in this lineup. Designed to enhance the viewing experience, these mounts cater primarily to professional settings such as conference rooms, classrooms, and digital signage applications.The ST 630P-S features a universal design that supports a variety of flat-panel displays. One of its main features is the push-button height adjustment, allowing users to easily reposition the screen to their desired viewing height. This flexibility not only enhances comfort but also ensures optimal viewer engagement, making it an ideal choice for both collaborative environments and presentations.

The ST 630 model is engineered for heavy-duty applications, providing robust support for larger screens. It boasts a sleek appearance that complements modern decor while ensuring durability. One of its hallmark characteristics is the integrated cable management system, which helps maintain a tidy look by concealing unsightly wires. This feature not only enhances aesthetics but also contributes to safety by minimizing tripping hazards.

On the other hand, the ST 630P model takes user-friendliness to the next level. It incorporates advanced tilt and swivel capabilities, enabling users to adjust the screen's angle easily. This is especially beneficial in settings where viewers are positioned at varying heights or angles, ensuring everyone has an uninterrupted view of the presentation or display.

In addition to their ergonomic designs, all three models share a commitment to quality construction and safety. They are engineered to meet or exceed industry standards, providing peace of mind for users. The use of premium materials ensures that these mounts can withstand the rigors of daily use without compromising stability.

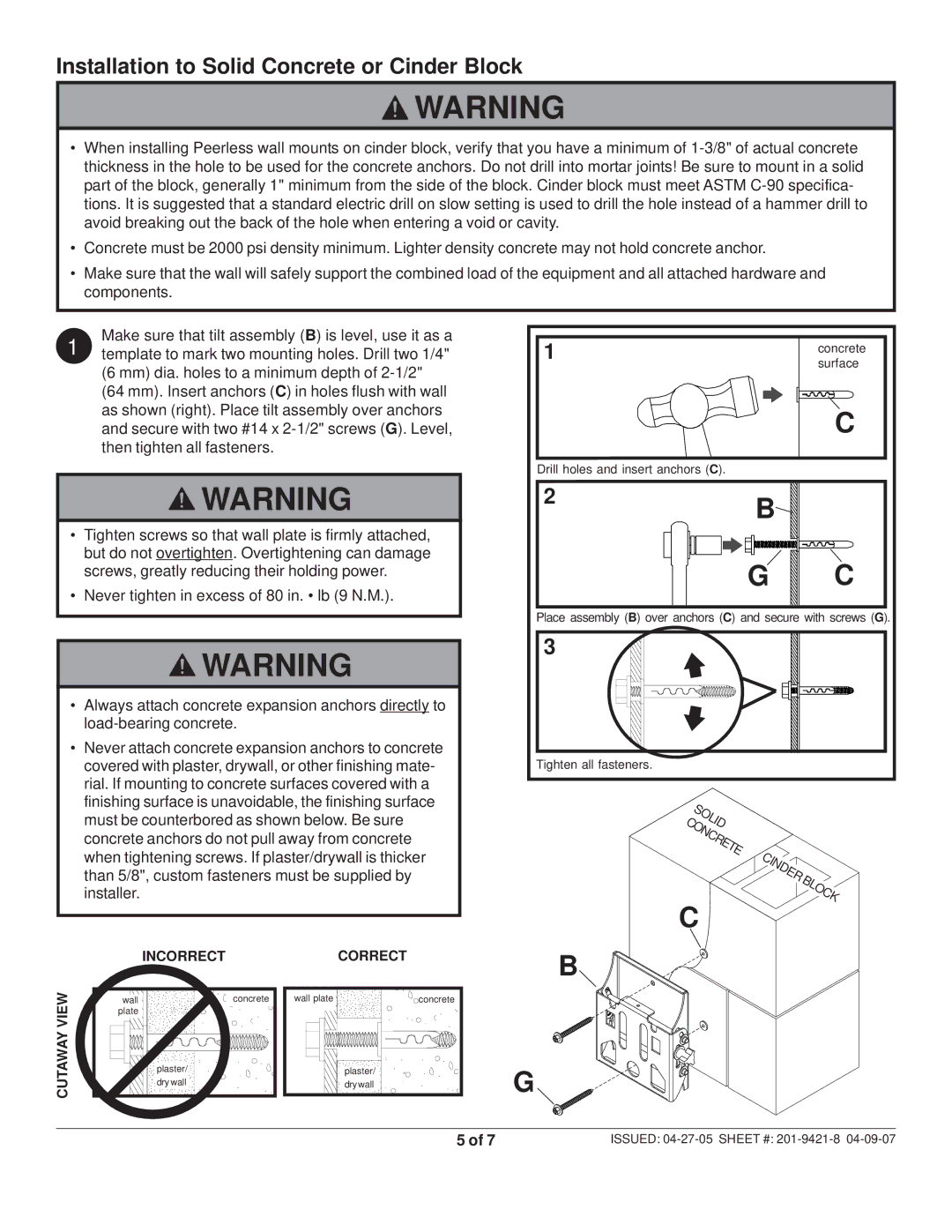

All three mounts are straightforward to install, often requiring minimal tools and time. This ease of installation is a testament to Peerless Industries' focus on user experience.

In conclusion, the ST 630P-S, ST 630, and ST 630P models from Peerless Industries exemplify the perfect blend of functionality, aesthetics, and safety. With features tailored for different environments and user needs, these mounts stand out as top choices for anyone looking to enhance their audiovisual setup.