ASSEMBLY

ASSEMBLY TOOLS REQUIRED

*Blade wrenches (supplied)

*1/2” and 3/8” open end or socket wrenches (not included)

*5/16” hex wrench (not included)

*Flat screwdriver and hammer (not included)

ASSEMBLY TIME ESTIMATE - 2-3 hrs.

THE 12" RADIAL ARM SAW IS VERY HEAVY AND REQUIRES SEVERAL PEOPLE TO LIFT AND MANUEVER IT DURING ASSEMBLY.

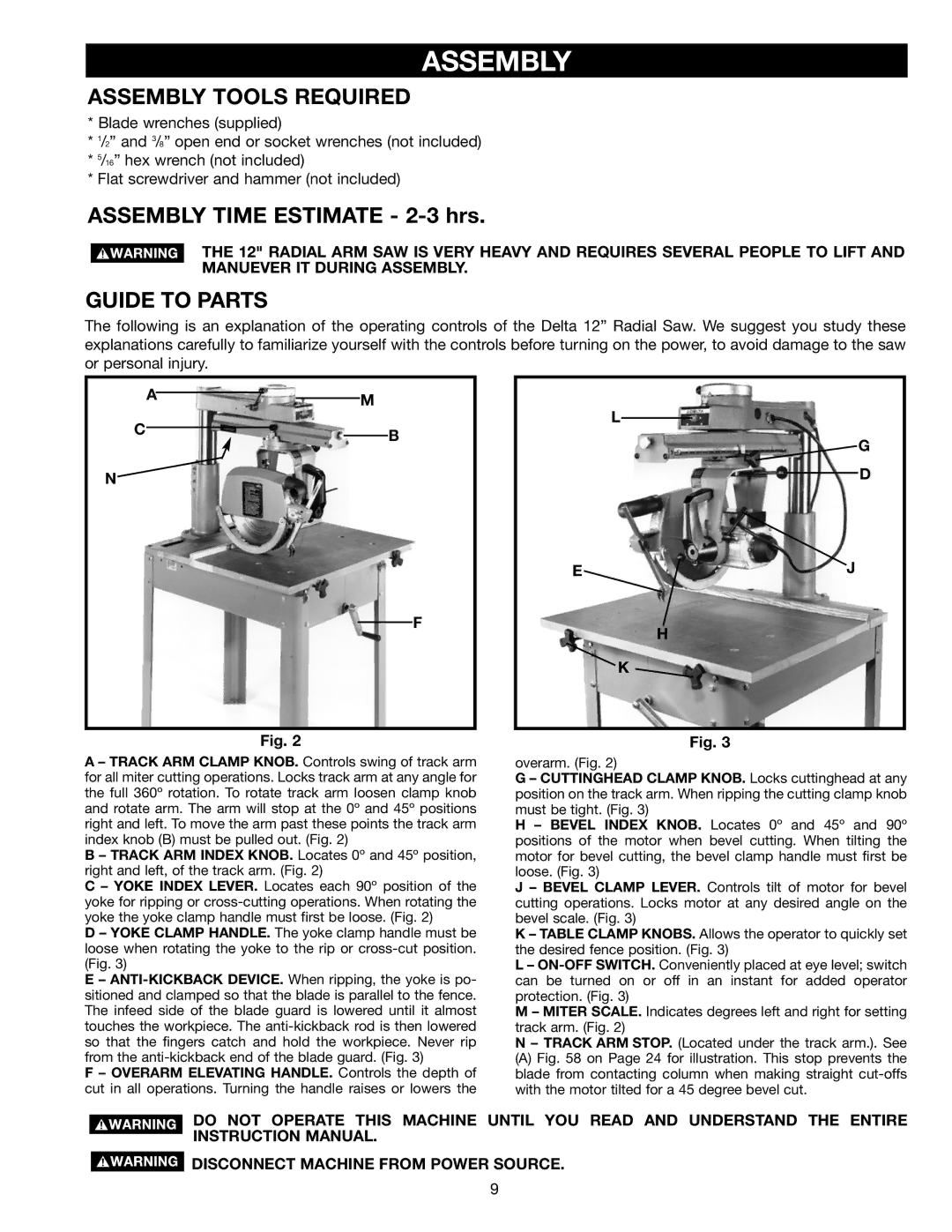

GUIDE TO PARTS

The following is an explanation of the operating controls of the Delta 12” Radial Saw. We suggest you study these explanations carefully to familiarize yourself with the controls before turning on the power, to avoid damage to the saw or personal injury.

A![]()

![]() M

M

C![]()

![]() B

B

N

F

L

![]() G

G

D

EJ

H

K

Fig. 2

A – TRACK ARM CLAMP KNOB. Controls swing of track arm for all miter cutting operations. Locks track arm at any angle for the full 360º rotation. To rotate track arm loosen clamp knob and rotate arm. The arm will stop at the 0º and 45º positions right and left. To move the arm past these points the track arm index knob (B) must be pulled out. (Fig. 2)

B – TRACK ARM INDEX KNOB. Locates 0º and 45º position, right and left, of the track arm. (Fig. 2)

C – YOKE INDEX LEVER. Locates each 90º position of the yoke for ripping or

D – YOKE CLAMP HANDLE. The yoke clamp handle must be loose when rotating the yoke to the rip or

E –

F – OVERARM ELEVATING HANDLE. Controls the depth of cut in all operations. Turning the handle raises or lowers the

Fig. 3

overarm. (Fig. 2)

G – CUTTINGHEAD CLAMP KNOB. Locks cuttinghead at any position on the track arm. When ripping the cutting clamp knob must be tight. (Fig. 3)

H – BEVEL INDEX KNOB. Locates 0º and 45º and 90º positions of the motor when bevel cutting. When tilting the motor for bevel cutting, the bevel clamp handle must first be loose. (Fig. 3)

J – BEVEL CLAMP LEVER. Controls tilt of motor for bevel cutting operations. Locks motor at any desired angle on the bevel scale. (Fig. 3)

K – TABLE CLAMP KNOBS. Allows the operator to quickly set the desired fence position. (Fig. 3)

L –

M – MITER SCALE. Indicates degrees left and right for setting track arm. (Fig. 2)

N – TRACK ARM STOP. (Located under the track arm.). See

(A)Fig. 58 on Page 24 for illustration. This stop prevents the blade from contacting column when making straight cut-offs with the motor tilted for a 45 degree bevel cut.

DO NOT OPERATE THIS MACHINE UNTIL YOU READ AND UNDERSTAND THE ENTIRE INSTRUCTION MANUAL.

DISCONNECT MACHINE FROM POWER SOURCE.

DISCONNECT MACHINE FROM POWER SOURCE.

9