MITER GAGE OPERATION AND ADJUSTMENTS

When straight

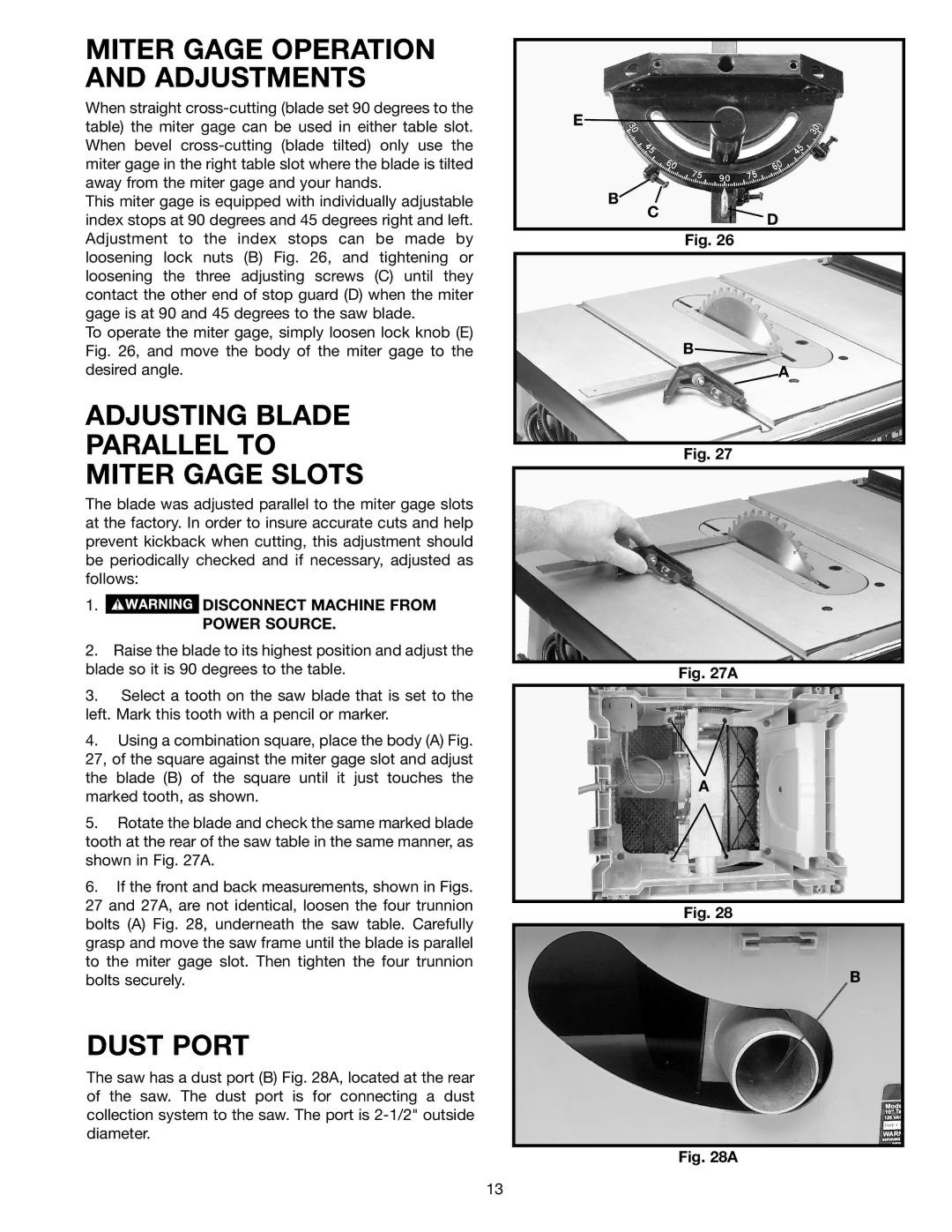

This miter gage is equipped with individually adjustable index stops at 90 degrees and 45 degrees right and left. Adjustment to the index stops can be made by loosening lock nuts (B) Fig. 26, and tightening or loosening the three adjusting screws (C) until they contact the other end of stop guard (D) when the miter gage is at 90 and 45 degrees to the saw blade.

To operate the miter gage, simply loosen lock knob (E) Fig. 26, and move the body of the miter gage to the desired angle.

ADJUSTING BLADE

PARALLEL TO

MITER GAGE SLOTS

The blade was adjusted parallel to the miter gage slots at the factory. In order to insure accurate cuts and help prevent kickback when cutting, this adjustment should be periodically checked and if necessary, adjusted as follows:

1.  DISCONNECT MACHINE FROM

DISCONNECT MACHINE FROM

POWER SOURCE.

2.Raise the blade to its highest position and adjust the blade so it is 90 degrees to the table.

3.Select a tooth on the saw blade that is set to the left. Mark this tooth with a pencil or marker.

4.Using a combination square, place the body (A) Fig. 27, of the square against the miter gage slot and adjust the blade (B) of the square until it just touches the marked tooth, as shown.

5.Rotate the blade and check the same marked blade tooth at the rear of the saw table in the same manner, as shown in Fig. 27A.

6.If the front and back measurements, shown in Figs.

27and 27A, are not identical, loosen the four trunnion bolts (A) Fig. 28, underneath the saw table. Carefully grasp and move the saw frame until the blade is parallel to the miter gage slot. Then tighten the four trunnion bolts securely.

DUST PORT

The saw has a dust port (B) Fig. 28A, located at the rear of the saw. The dust port is for connecting a dust collection system to the saw. The port is

E![]()

B

C![]() D Fig. 26

D Fig. 26

B![]()

A

Fig. 27

Fig. 27A

A

Fig. 28

B

Fig. 28A

13