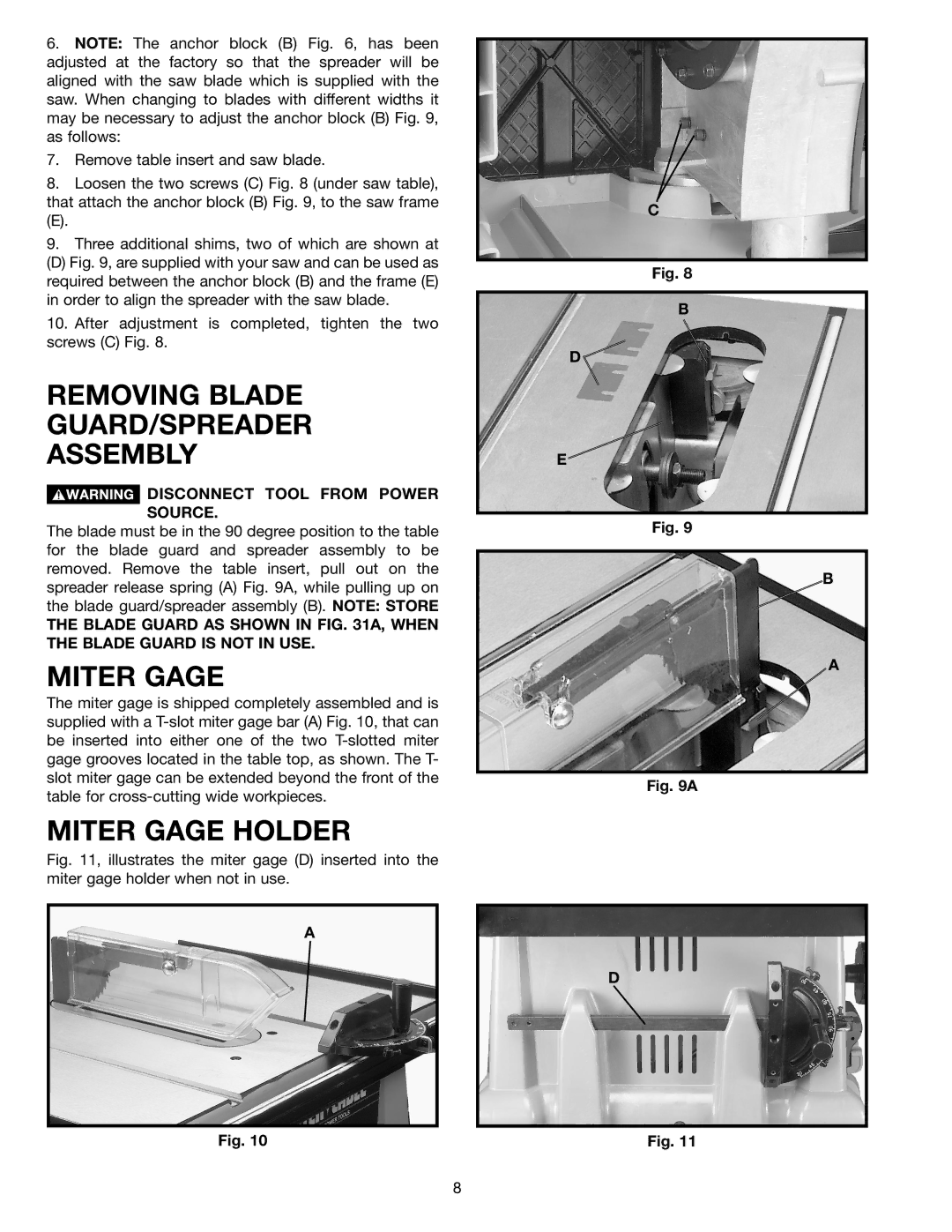

6.NOTE: The anchor block (B) Fig. 6, has been adjusted at the factory so that the spreader will be aligned with the saw blade which is supplied with the saw. When changing to blades with different widths it may be necessary to adjust the anchor block (B) Fig. 9, as follows:

7.Remove table insert and saw blade.

8.Loosen the two screws (C) Fig. 8 (under saw table), that attach the anchor block (B) Fig. 9, to the saw frame

(E).

9.Three additional shims, two of which are shown at

(D) Fig. 9, are supplied with your saw and can be used as required between the anchor block (B) and the frame (E) in order to align the spreader with the saw blade.

10.After adjustment is completed, tighten the two screws (C) Fig. 8.

REMOVING BLADE

GUARD/SPREADER

ASSEMBLY

DISCONNECT TOOL FROM POWER SOURCE.

DISCONNECT TOOL FROM POWER SOURCE.

The blade must be in the 90 degree position to the table for the blade guard and spreader assembly to be removed. Remove the table insert, pull out on the spreader release spring (A) Fig. 9A, while pulling up on the blade guard/spreader assembly (B). NOTE: STORE

THE BLADE GUARD AS SHOWN IN FIG. 31A, WHEN THE BLADE GUARD IS NOT IN USE.

MITER GAGE

The miter gage is shipped completely assembled and is supplied with a

MITER GAGE HOLDER

Fig. 11, illustrates the miter gage (D) inserted into the miter gage holder when not in use.

A

Fig. 10

C

Fig. 8

B

D![]()

E

Fig. 9

Fig. 9A

D

Fig. 11

B

A

8