Manuel d’instructions Manual de instrucciones

California Proposition

Table of Contents

Support and Clamp Work

Safety Guidelines Definitions

Prohibition

General Safety Instructions Before Using this Power Tool

Power Tool Safety

Bench Grinder Safety

Bench Grinder Safety

Guidelines for Extension Cords

Electrical Requirements and Safety

Power Supply and Motor Specifications

Grounding Instructions

Tools Needed for Assembly

Know Your Bench Grinder

Installing the EYE Shields FIG. E

Assembly and Adjustments

Installing Tool Rests FIG. A, B, C

Installing the Spark Guards FIG. D

Never USE a Grinding Wheel Without a Blotter

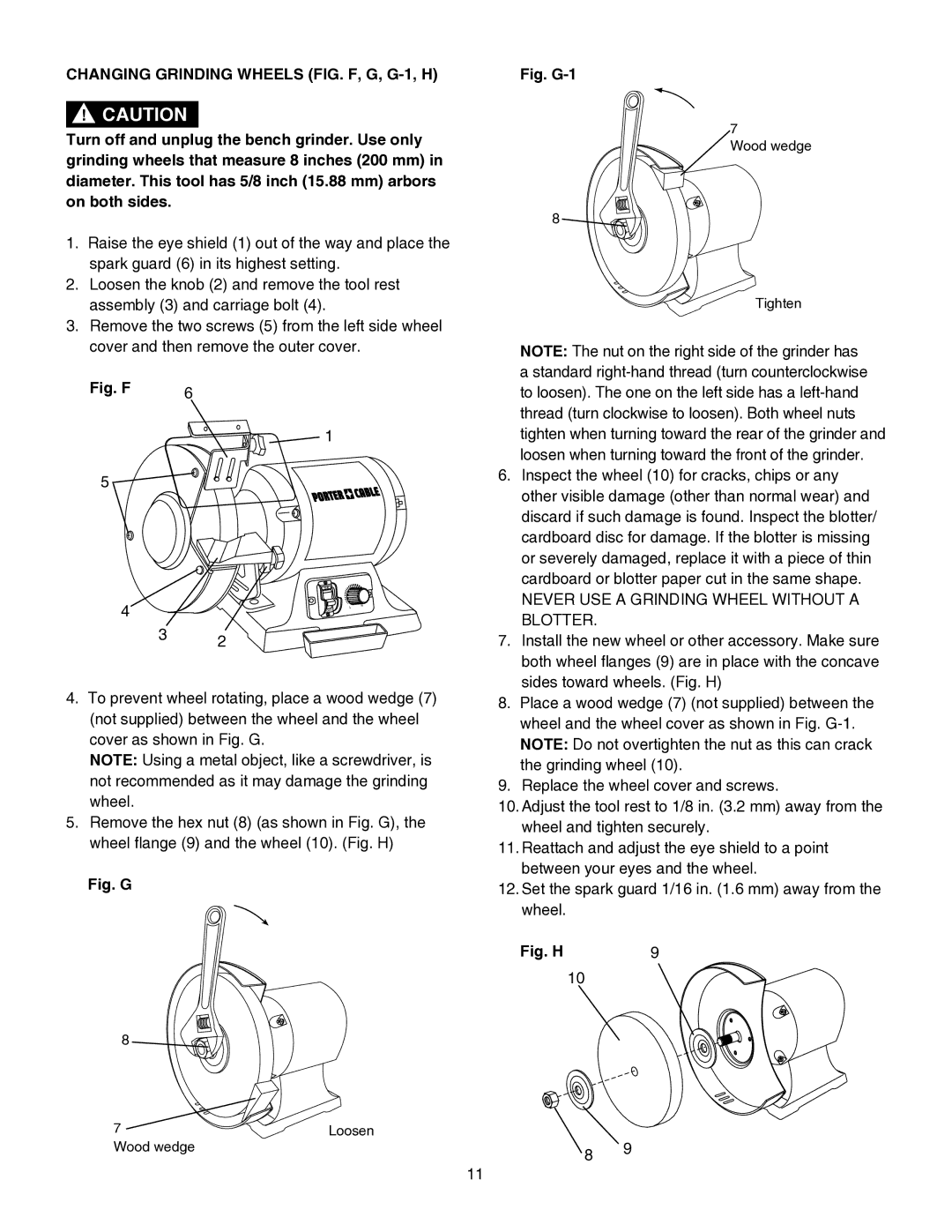

Changing Grinding Wheels FIG. F, G, G-1, H

Replacing the Bulb FIG

Installing the Coolant Tray FIG. J

Cooling Workpiece FIG. P

Using the Worklight FIG. N

Adjusting the Speed of Grinder FIG. O

Operation

Screwdrivers

General Operation

Scissors

Knives

General

Maintenance

Problem Problem Cause Suggested Corrective Action

Troubleshooting Guide

Replacement Parts Service and Repairs

Available Accessories

Accessories and Attachments

MM Variable Speed Grinder with Worklight Parts List

Parts List

MM Variable Speed Grinder with Worklight Schematic

Three Year Limited Warranty

Warranty

Advertencia Léase Este

Moteur Meule

Table DES Matières

Proposition 65 DE LA Californie

Soutenir ET Bien Serrer LES Pièces

Symboles D’AVERTISSEMENT

Mesures DE Sécurité Définitions

Interdiction

Toujours Porter DES Lunettes DE

Consignes DE Sécurité Outil Électrique

NE PAS SE Pencher AU Dessus DE

Sécurité Pour LA Meuleuse SUR Pied

Directives DE Mise À LA Terre

Caractéristiques Électriques ET Sécurité

Boucliers Protecteurs ET Pareétincelles

Données Techniques SUR LE Moteur ET L’ALIMENTATION

Calibre Minimum DES Rallonges AWG

Directives Concernant LES Rallonges

Tableau DES Pièces Détachées ART Description Quantité

Déballage DE LA Meuleuse SUR Pied

Déballage ET Vérification DU Contenu

Parties DE LA Meuleuse SUR Pied

Installation DES Protecteurs Oculaires FIG. E

Installation DES Appuis D’OUTIL FIG. A, B, C

Installation DES PARE-ÉTINCELLES FIG. D

Remplacement DES Meules FIG. F, G, G-1, H

Fig. J

Installation DU BAC D’ARROSAGE FIG. J

Refroidissement DE LA Pièce FIG. P

Utilisation

Démarrage ET Arrêt DE LA Meuleuse FIG. M

Utilisation DE LA Lampe DE Travail FIG. N

Tournevis

Fonctionnement

Ciseaux

Couteaux

Généralités

Entretien

Guide DE Dépannage

Pièces DE Rechange Service APRÈS-VENTE ET Réparations

Problème Cause Probable Solution Conseillée

Accessoires Offerts EN Option

Accessoires

Liste DE Pièces

Liste DE Pièces

X4BC

Schéma

Remarque

Garantie Limitée DE Trois 3 ANS

Garantie

Número DE Catálogo PCB575BG

Sección Página

Índice

Especificaciones DEL Producto

Proposicion 65 DE California

Apoye LA Pieza DE Trabajo Y Asegurela CON Abrazaderas

Pautas DE SEGURIDAD/DEFINICIONES

Iconos DE Advertencia

Prohibido

Utilice LOS Accesorios Recomendados

Utilice Siempre Proteccion Para LOS Ojos

Seguridad EN EL Manejo DE Herramientas Eléctricas

Seguridad EN EL Manejo DE LA Moledora DE Banco

Instrucciones Para LA Conexión a Tierra

Requisitos Eléctricos Y Deseguridad

EN Caso DE QUE Alguna Pieza DE

Especificaciones DEL Suministro Eléctrico Y DEL Motor

Calibre Minimo Para Extensiones Electricas AWG

Extensiones Electricas

Tabla DE Piezas Sueltas Artículo Descripción Cantidad

Desempaque DE LA Moledora DE Banco

Desempaque Y Verificación DEL Contenido

Protector contra las chispas

Conozca SU Moledora DE Banco

Instalación DE LOS Protectores Para LOS Ojos FIG. E

Ensamble Y Ajustes

Instalacion DE LOS Soportes Para Herramientas FIG. A, B, C

Instalación DE LOS Protectores Contra Chispas FIG. D

Fig. F

Cambio DE LAS Muelas Abrasivas FIG. F, G, G-1, H

Almacenaje DE LA Herramienta

Reemplazo DEL Foco FIG

Instalación DE LA Bandeja DE Refrigerante FIG. J

Montaje DE LA Herramienta Sobre UN Banco DE Trabajo FIG. K

Ajuste DE Lavelocidad DE Laamoladora FIG. O

Funcionamiento

Como Encender Y Apagar LA Moledora FIG. M

USO DE LA LUZ DE Trabajo FIG. N

Destornilladores

Trabajos Generales

Tijeras

Cuchillos

Generales

Mantenimiento

Piezas DE Repuesto Servicio Y Reparaciones

Guia Para LA Solucion DE Problemas

Problema Causa DEL / Problema Acción Correctiva Sugerida

Accesorios Disponibles

Accesorios Y Acoplamientos

Lista DE Piezas

Lista DE Piezas

X4BC

Esquema

Nota

Garantia Limitada POR Tres AÑO

Garantía

![]()

![]()

![]() 1

1![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() Tighten

Tighten