Beveling

To cut a bevel, lock the fence at the required angle and run the work across the knives while keeping it firmly against the fence and tables. Several passes may be necessary to achieve the desired result.

Taper Cuts

One of the most useful jointer operations is cutting an edge to a taper. The method can be used on a wide variety of work. Tapered legs of furniture are a common example.

Instead of laying the piece on the infeed table, lower the forward end of the work onto the outfeed table.

Do this very carefully, as the piece will span the knives, and they will take a "bite" from the work with a tendency to kick back unless the piece is firmly held. Now push the work forward as in ordinary jointing.

The effect is to plane off all the stock in front of the knives to increase depth, leaving a tapered surface.The ridge left by the knives when starting the taper may be removed by taking a very light cut according to the regular method for jointing, with the infeed table raised to its usual position.

Practice is required in taper operations, and the beginner is advised to make trial cuts on waste material. Taper cuts over part of the length and a number of other special operations can easily be done as the operator gains experience.

Maintenance

![]() Disconnect machine from power source before performing maintenance.

Disconnect machine from power source before performing maintenance.

Check all screws and fasteners occasionally and keep them tightened securely.

The table and fence surfaces must be kept clean and free of rust for best results. Some users prefer a paste wax coating. Aerosol protectants are also available at hardware and tool stores.

Lubrication

Use a high grade light grease on the steel adjusting screws for the raising and lowering mechanisms of the infeed and outfeed work tables.

The cutterhead runs in two

Cutterhead Repairs

The entire cutterhead assembly may be removed for bearing replacement or other cutterhead maintenance procedures.

To remove the cutterhead:

1.Disconnect machine from power source.

2.Lower infeed and outfeed tables.

3.Remove rabbeting ledge and fence.

4.Remove belts.

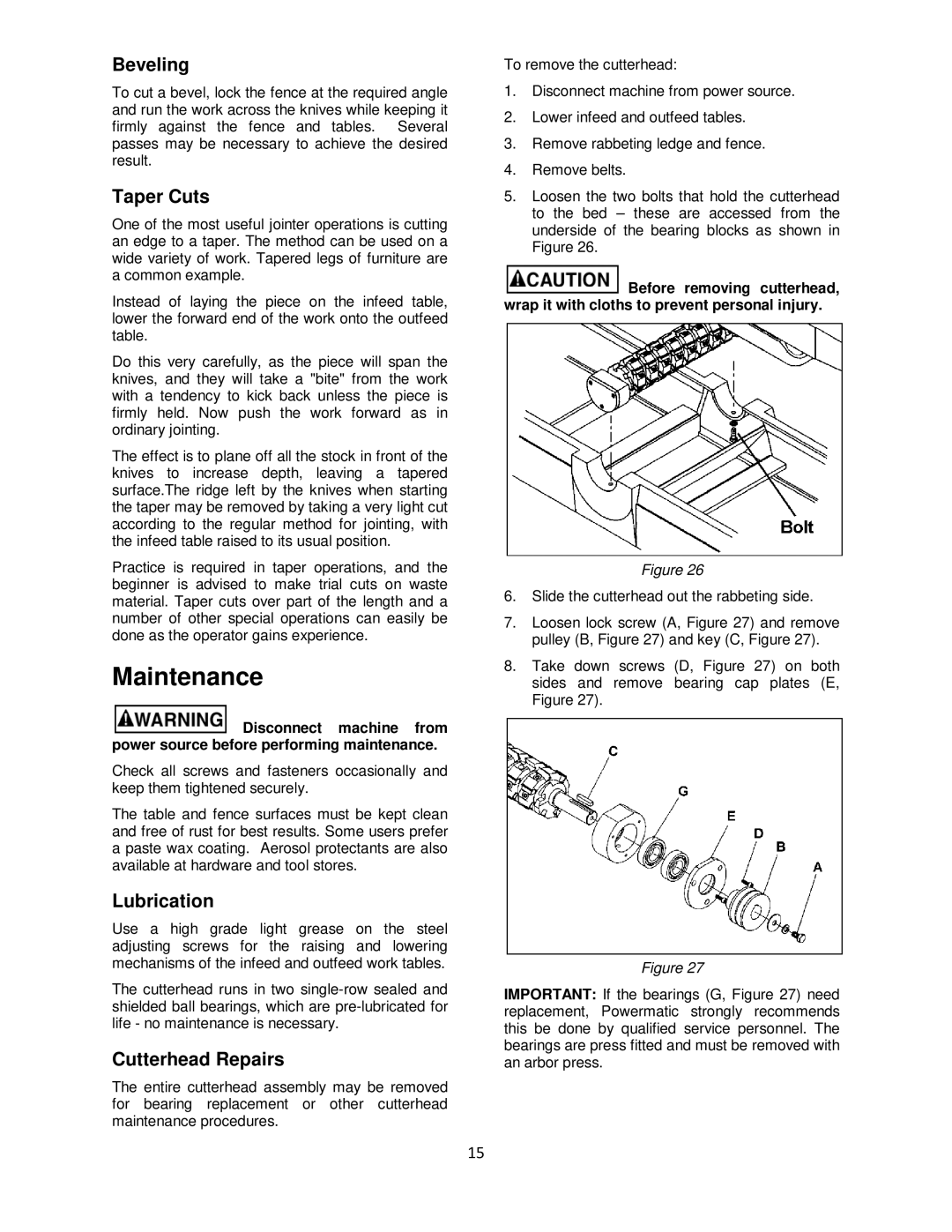

5.Loosen the two bolts that hold the cutterhead to the bed – these are accessed from the underside of the bearing blocks as shown in Figure 26.

![]() Before removing cutterhead, wrap it with cloths to prevent personal injury.

Before removing cutterhead, wrap it with cloths to prevent personal injury.

Figure 26

6.Slide the cutterhead out the rabbeting side.

7.Loosen lock screw (A, Figure 27) and remove pulley (B, Figure 27) and key (C, Figure 27).

8.Take down screws (D, Figure 27) on both sides and remove bearing cap plates (E, Figure 27).

Figure 27

IMPORTANT: If the bearings (G, Figure 27) need replacement, Powermatic strongly recommends this be done by qualified service personnel. The bearings are press fitted and must be removed with an arbor press.

15