2.Replace the installed magnetic switch with the switch rated for 460V operation (stock no.

3.Change the dial on the overload relay to the appropriate setting for 460V operation.

4.Check for proper direction of rotation (cutterhead should rotate toward infeed table). If rotation is in the wrong direction, disconnect machine and switch any two of the hot leads. Reconnect power and confirm proper rotation.

Adjustments

Tools required 17mm/19mm wrench

Drive Belt

Remove the three crown nuts and washers (A, Figure 10) on the belt cover with a 17mm wrench, and remove the cover. Use a 19mm wrench to adjust the nuts in the motor support (B, Figure 11).

Raise or lower motor support to obtain proper tension, then

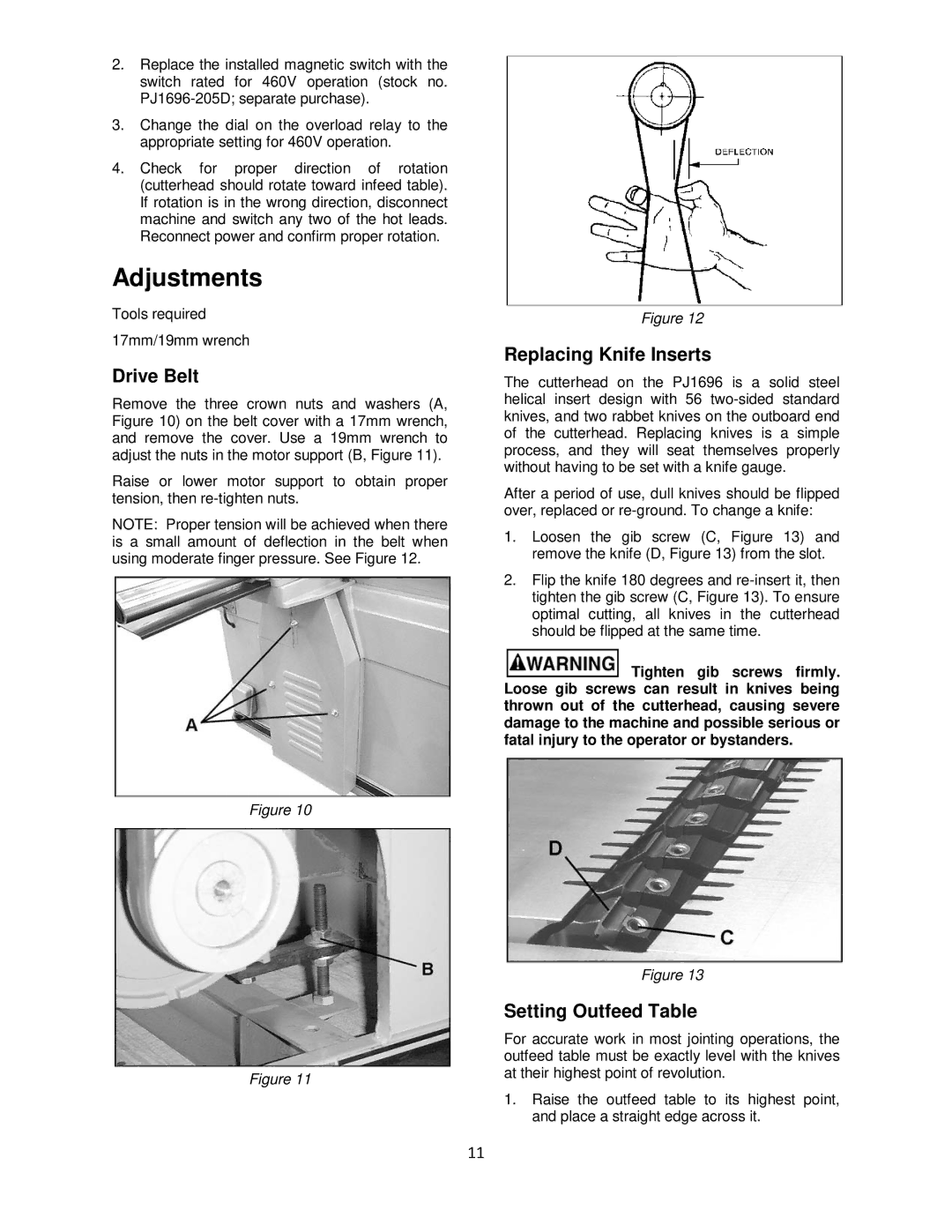

NOTE: Proper tension will be achieved when there is a small amount of deflection in the belt when using moderate finger pressure. See Figure 12.

Figure 12

Replacing Knife Inserts

The cutterhead on the PJ1696 is a solid steel helical insert design with 56

After a period of use, dull knives should be flipped over, replaced or

1.Loosen the gib screw (C, Figure 13) and remove the knife (D, Figure 13) from the slot.

2.Flip the knife 180 degrees and

![]() Tighten gib screws firmly. Loose gib screws can result in knives being thrown out of the cutterhead, causing severe damage to the machine and possible serious or fatal injury to the operator or bystanders.

Tighten gib screws firmly. Loose gib screws can result in knives being thrown out of the cutterhead, causing severe damage to the machine and possible serious or fatal injury to the operator or bystanders.

Figure 10

Figure 11

Figure 13

Setting Outfeed Table

For accurate work in most jointing operations, the outfeed table must be exactly level with the knives at their highest point of revolution.

1.Raise the outfeed table to its highest point, and place a straight edge across it.

11