Figure 7

Dust Hood

Mount the dust hood (C, Figure 8), to the left side of the jointer using the seven

It is recommended a dust collection system of appropriate size (at least 800 CFM) be connected to the dust outlet via a 6" diameter hose.

Figure 8

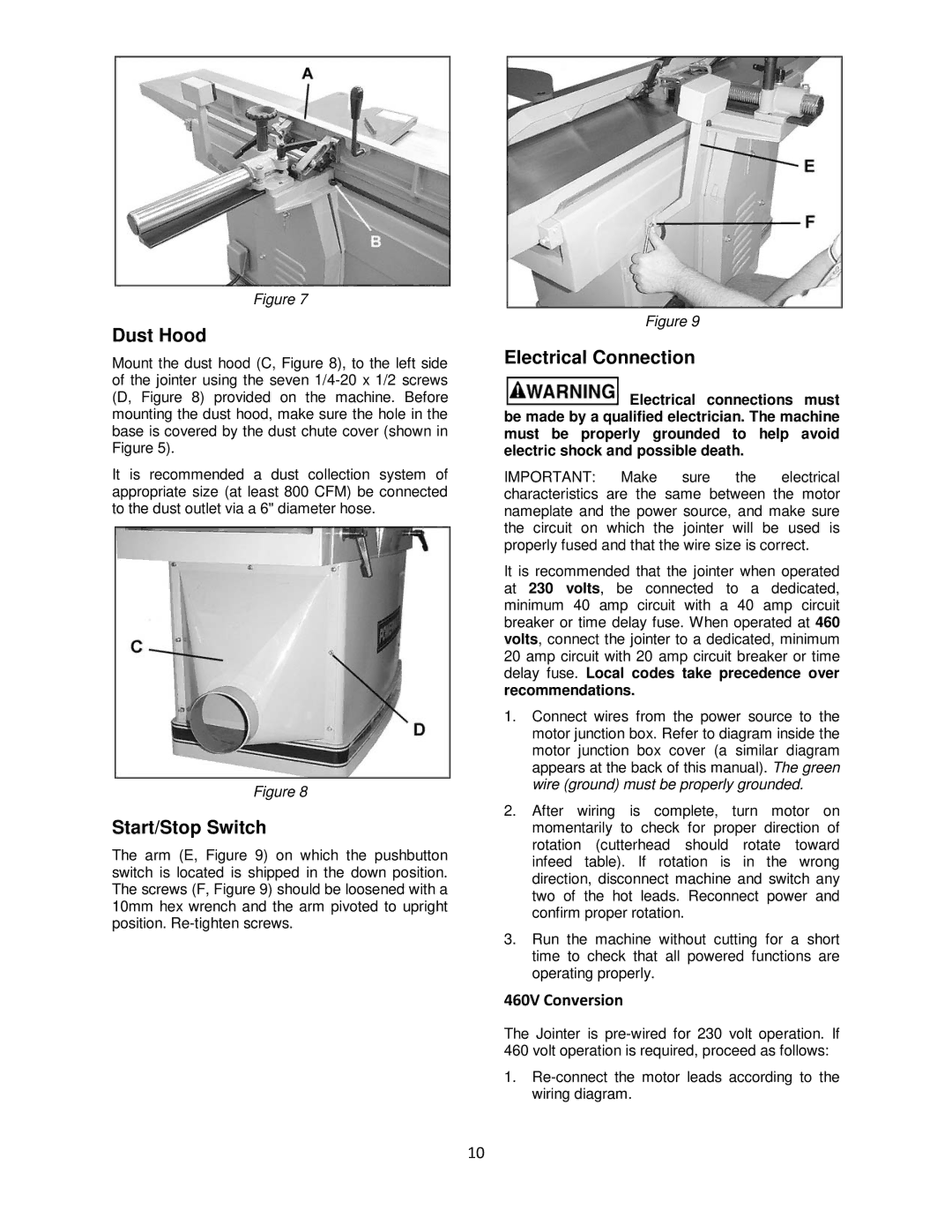

Start/Stop Switch

The arm (E, Figure 9) on which the pushbutton switch is located is shipped in the down position. The screws (F, Figure 9) should be loosened with a 10mm hex wrench and the arm pivoted to upright position.

Figure 9

Electrical Connection

![]() Electrical connections must be made by a qualified electrician. The machine must be properly grounded to help avoid electric shock and possible death.

Electrical connections must be made by a qualified electrician. The machine must be properly grounded to help avoid electric shock and possible death.

IMPORTANT: Make sure the electrical characteristics are the same between the motor nameplate and the power source, and make sure the circuit on which the jointer will be used is properly fused and that the wire size is correct.

It is recommended that the jointer when operated at 230 volts, be connected to a dedicated, minimum 40 amp circuit with a 40 amp circuit breaker or time delay fuse. When operated at 460 volts, connect the jointer to a dedicated, minimum 20 amp circuit with 20 amp circuit breaker or time delay fuse. Local codes take precedence over recommendations.

1.Connect wires from the power source to the motor junction box. Refer to diagram inside the motor junction box cover (a similar diagram appears at the back of this manual). The green wire (ground) must be properly grounded.

2.After wiring is complete, turn motor on momentarily to check for proper direction of rotation (cutterhead should rotate toward infeed table). If rotation is in the wrong direction, disconnect machine and switch any two of the hot leads. Reconnect power and confirm proper rotation.

3.Run the machine without cutting for a short time to check that all powered functions are operating properly.

460V Conversion

The Jointer is

460 volt operation is required, proceed as follows:

1.

10