Maintenance

![]() Before doing maintenance on the machine, disconnect it from the electrical supply by pulling out the plug or switching off the main switch! Failure to comply may cause serious injury.

Before doing maintenance on the machine, disconnect it from the electrical supply by pulling out the plug or switching off the main switch! Failure to comply may cause serious injury.

Interior of oil tank must be kept clean at all times.

The track of caterpillar chain must be kept lubricated at all times by the machine's lubrication system.

Oil should be checked weekly, and more added if necessary. Use light

Refill the oil in the gear reducer until the level reaches over half its full capacity.

Properly clean chips and sawdust from your machine after work operations are complete. Never use your hands, use a brush or compressed air.

Optional Accessory

Part No. | Description |

Laser Assembly |

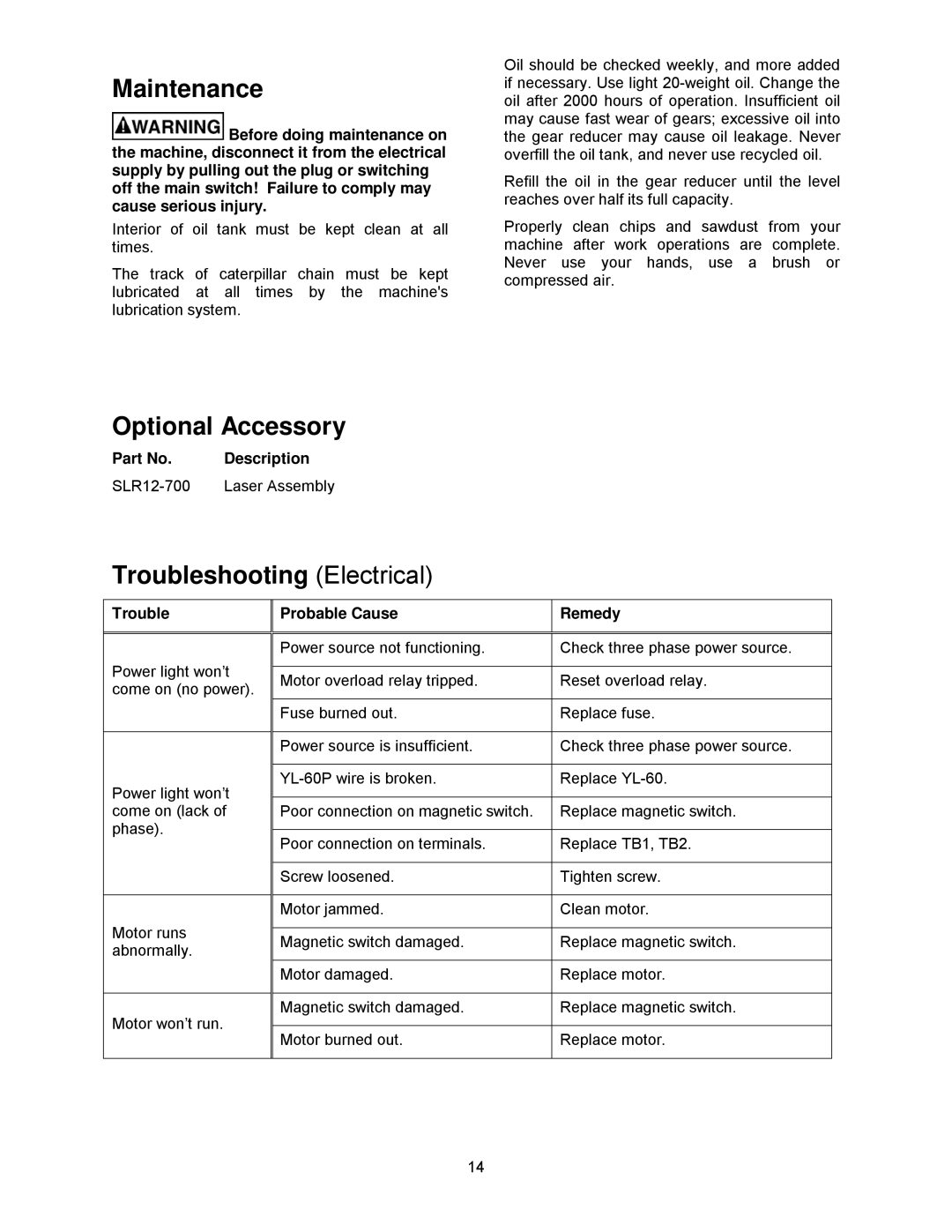

Troubleshooting (Electrical)

Trouble | Probable Cause | Remedy | |

|

|

| |

| Power source not functioning. | Check three phase power source. | |

Power light won’t |

|

| |

Motor overload relay tripped. | Reset overload relay. | ||

come on (no power). | |||

|

| ||

| Fuse burned out. | Replace fuse. | |

|

|

| |

| Power source is insufficient. | Check three phase power source. | |

|

|

| |

Power light won’t | Replace | ||

|

| ||

|

| ||

come on (lack of | Poor connection on magnetic switch. | Replace magnetic switch. | |

phase). |

|

| |

Poor connection on terminals. | Replace TB1, TB2. | ||

| |||

|

|

| |

| Screw loosened. | Tighten screw. | |

|

|

| |

| Motor jammed. | Clean motor. | |

Motor runs |

|

| |

Magnetic switch damaged. | Replace magnetic switch. | ||

abnormally. | |||

|

| ||

| Motor damaged. | Replace motor. | |

|

|

| |

Motor won’t run. | Magnetic switch damaged. | Replace magnetic switch. | |

|

| ||

Motor burned out. | Replace motor. | ||

| |||

|

|

|

14