CHT2250 specifications

The RedMax CHT2250 is a state-of-the-art hedge trimmer that combines power, precision, and performance, making it an ideal tool for both professional landscapers and DIY enthusiasts. Designed for efficiency and ease of use, this versatile machine is engineered to handle a variety of trimming tasks while ensuring that users can maintain comfort during extended periods of operation.One of the standout features of the CHT2250 is its robust engine, powering through thick branches and dense hedges with ease. The powerful two-stroke engine provides superior cutting performance while keeping fuel consumption low, allowing users to tackle larger projects without frequent refueling. The unit also features a lightweight design, reducing user fatigue and making it easier to maneuver during extended use.

The CHT2250 comes equipped with a double-sided blade that offers dual-action cutting, significantly enhancing efficiency. The sharp and durable blades are designed to make clean cuts, promoting healthier growth for the plants being trimmed. The adjustable angle feature allows users to reach tricky spots and achieve clean edges without straining, adding to the versatility of the tool.

In addition to its impressive cutting capabilities, the RedMax CHT2250 incorporates several innovative technologies aimed at user comfort and safety. The anti-vibration system minimizes fatigue during operation, offering a smoother experience when using the trimmer for long periods. The ergonomic design of the handle ensures a firm grip, enhancing control and precision.

Safety is also a priority with the CHT2250, featuring a safety switch that prevents accidental starts. This added layer of protection is critical when working in various environments, ensuring that the tool only operates when intended.

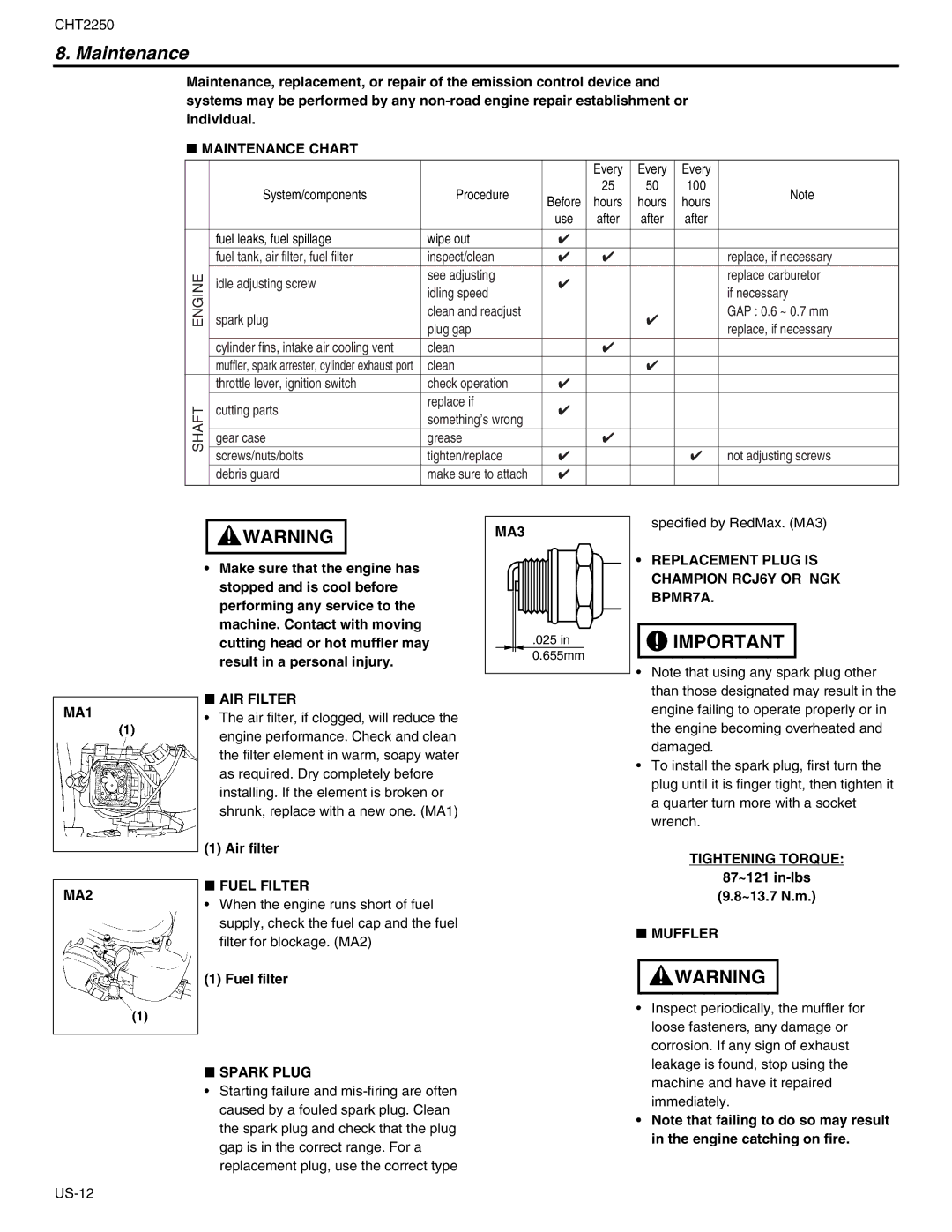

Furthermore, the easy-access air filter and spark plug make maintenance straightforward, allowing users to keep their equipment in optimal condition. Overall, the RedMax CHT2250 is built for durability, ensuring that it withstands the rigors of continuous use, while providing top-notch performance.

In conclusion, the RedMax CHT2250 hedge trimmer is a standout choice for anyone looking to maintain their landscape effectively. Its powerful engine, efficient cutting system, user-friendly design, and commitment to safety make it not just a tool, but an essential partner for achieving landscape perfection. Whether it's for professional landscaping or home gardening, the CHT2250 delivers unmatched quality and reliability.