Chain Saw Information

Saw Chain Tension Adjustment

WARNING: Unplug chain saw from power source before adjusting saw chain tension.

WARNING: Cutting edges on chain are sharp. Use protective gloves when handling chain.

WARNING: Maintain proper chain tension always. A loose chain will in- crease the risk of kickback.Aloose chain may jump out of guide bar groove. This may injure operator and damage chain.A loose chain will cause chain, guide bar, and sprocket to wear rapidly.

Note: For

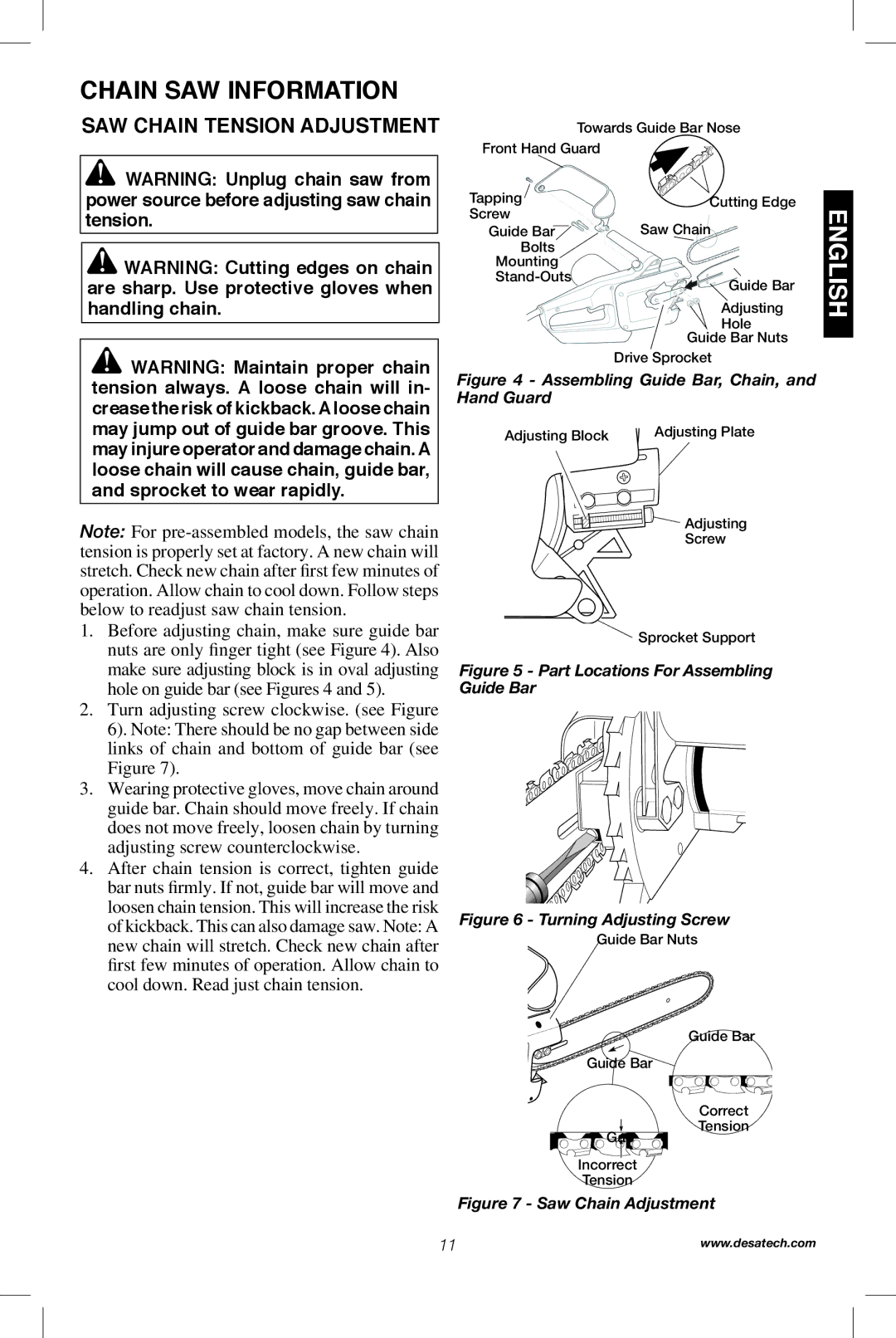

1.Before adjusting chain, make sure guide bar nuts are only finger tight (see Figure 4). Also make sure adjusting block is in oval adjusting hole on guide bar (see Figures 4 and 5).

2.Turn adjusting screw clockwise. (see Figure 6). Note: There should be no gap between side links of chain and bottom of guide bar (see Figure 7).

3.Wearing protective gloves, move chain around guide bar. Chain should move freely. If chain does not move freely, loosen chain by turning adjusting screw counterclockwise.

4.After chain tension is correct, tighten guide bar nuts firmly. If not, guide bar will move and loosen chain tension. This will increase the risk of kickback. This can also damage saw. Note: A new chain will stretch. Check new chain after first few minutes of operation. Allow chain to cool down. Read just chain tension.

Towards Guide Bar Nose

Front Hand Guard |

|

|

Tapping | Cutting Edge | ENGLISH |

Screw | Adjusting | |

Guide Bar | Saw Chain |

|

Bolts |

|

|

Mounting |

|

|

Guide Bar |

| |

|

| |

| Hole |

|

| Guide Bar Nuts |

|

| Drive Sprocket |

|

Figure 4 - Assembling Guide Bar, Chain, and |

| |

Hand Guard |

|

|

Adjusting Block | Adjusting Plate |

|

| Adjusting |

|

| Screw |

|

![]() Sprocket Support

Sprocket Support

Figure 5 - Part Locations For Assembling Guide Bar

Figure 6 - Turning Adjusting Screw

Guide Bar Nuts

Guide Bar

Guide Bar

![]() Gap

Gap

Correct Tension

Incorrect

Tension

Figure 7 - Saw Chain Adjustment

11 | www.desatech.com |