CLEANING AND MAINTENANCE

Sharpening Saw Chain

WARNING: Unplug chain saw from power source before servicing. Severe injury or death could occur from electri- cal shock or body contact with moving chain.

WARNING: Cutting edges on chain are sharp. Use protective gloves when handling chain.

Keep chain sharp. Your saw will cut faster and more safely. A dull chain will cause undue sprock- et, guide bar, chain, and motor wear. If you must force chain into wood and cutting creates only saw dust with few large chips, chain is dull.

Items Needed to Sharpen Chain

Purchase these items from your local dealer, hard- ware store, or chain saw supplies outlet.

•5/32" round file

•Depth gauge tool

•File guide

•Vise

•Medium sized flat file

Sharpening Cutters

Use file guide for 30° filing.

1.Adjust chain for proper tension (see Saw Chain Tension Adjustment, page 11).

2.Clamp guide bar in vise to hold saw steady. Note: Do not clamp chain.

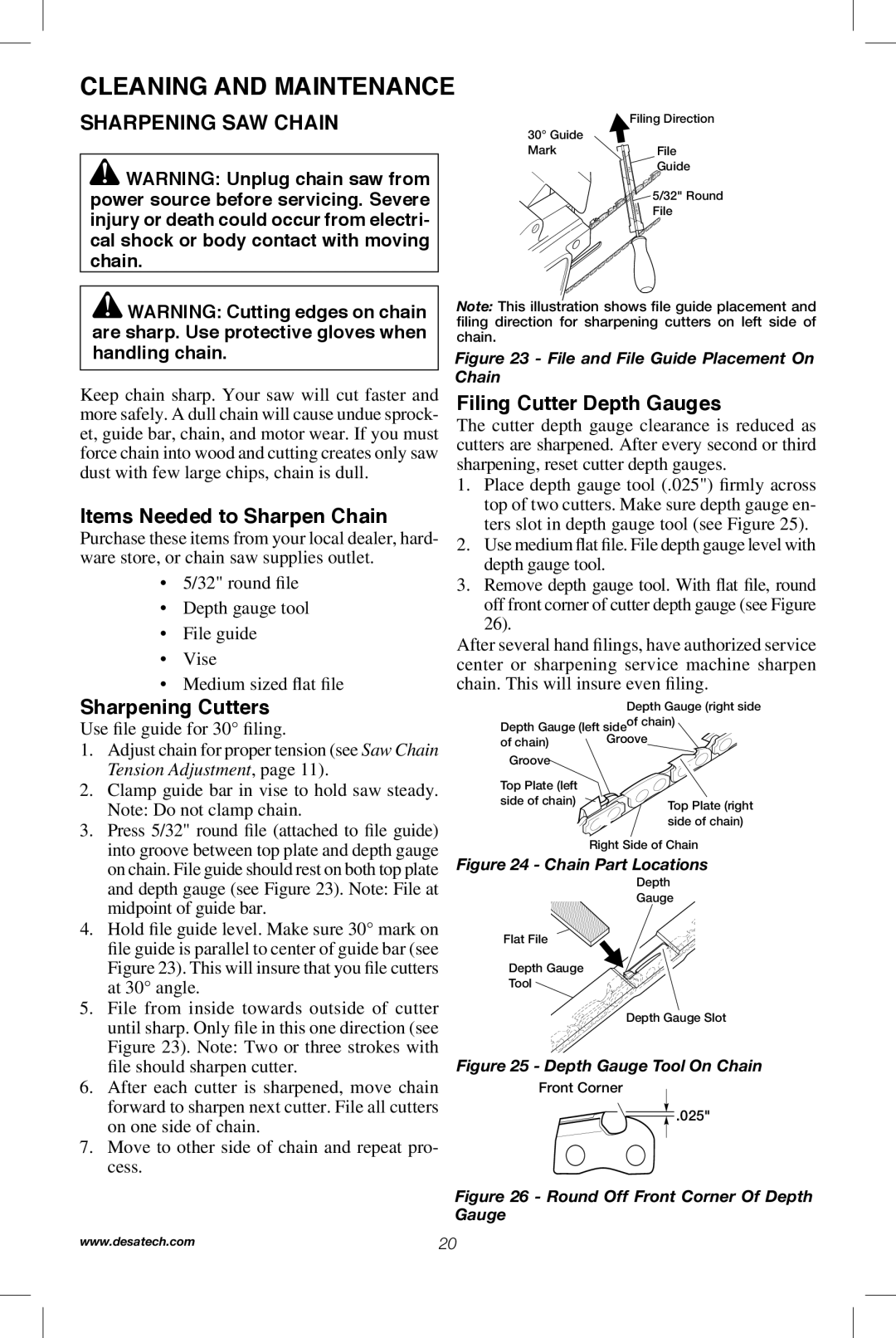

3.Press 5/32" round file (attached to file guide) into groove between top plate and depth gauge on chain. File guide should rest on both top plate and depth gauge (see Figure 23). Note: File at midpoint of guide bar.

4.Hold file guide level. Make sure 30° mark on file guide is parallel to center of guide bar (see Figure 23). This will insure that you file cutters at 30° angle.

5.File from inside towards outside of cutter until sharp. Only file in this one direction (see Figure 23). Note: Two or three strokes with file should sharpen cutter.

6.After each cutter is sharpened, move chain forward to sharpen next cutter. File all cutters on one side of chain.

7.Move to other side of chain and repeat pro- cess.

Filing Direction

30° Guide

MarkFile

![]() Guide

Guide

![]()

![]() 5/32" Round

5/32" Round

File

Note: This illustration shows file guide placement and filing direction for sharpening cutters on left side of chain.

Figure 23 - File and File Guide Placement On Chain

Filing Cutter Depth Gauges

The cutter depth gauge clearance is reduced as cutters are sharpened. After every second or third sharpening, reset cutter depth gauges.

1.Place depth gauge tool (.025") firmly across top of two cutters. Make sure depth gauge en- ters slot in depth gauge tool (see Figure 25).

2.Use medium flat file. File depth gauge level with depth gauge tool.

3.Remove depth gauge tool. With flat file, round off front corner of cutter depth gauge (see Figure 26).

After several hand filings, have authorized service center or sharpening service machine sharpen chain. This will insure even filing.

| Depth Gauge (right side |

Depth Gauge (left sideof chain) | |

of chain) | Groove |

Groove |

|

Top Plate (left |

|

side of chain) | Top Plate (right |

| |

| side of chain) |

Right Side of Chain

Figure 24 - Chain Part Locations

Depth

Gauge

Flat File

Depth Gauge

Tool

Depth Gauge Slot

Figure 25 - Depth Gauge Tool On Chain

Front Corner

![]() .025"

.025"

Figure 26 - Round Off Front Corner Of Depth Gauge

www.desatech.com | 20 |