Installing the water heater:

The water heater must be installed with a RTG20002B vent adapter or a UL approved Category III Stainless Steel equivalent.

![]() DANGER: Failure to install the vent adapter and properly vent the water heater to the outdoors as outlined in the Venting section of this manual will result in unsafe operation of the water heater causing death, serious injury, explosion, or fire. To avoid the risk of fire, explosion, or asphyxiation from carbon monoxide, NEVER operate the water heater unless it is properly vented and has adequate air supply for proper operation as outlined in the Venting section of this manual.

DANGER: Failure to install the vent adapter and properly vent the water heater to the outdoors as outlined in the Venting section of this manual will result in unsafe operation of the water heater causing death, serious injury, explosion, or fire. To avoid the risk of fire, explosion, or asphyxiation from carbon monoxide, NEVER operate the water heater unless it is properly vented and has adequate air supply for proper operation as outlined in the Venting section of this manual.

![]() WARNING: Use UL approved Category III Stainless Steel vent material only. No other vent material is permitted.

WARNING: Use UL approved Category III Stainless Steel vent material only. No other vent material is permitted.

![]() WARNING: Refer to page 7 for clearances to combustible material.

WARNING: Refer to page 7 for clearances to combustible material.

Venting

The installation of venting must comply with national codes, local codes, and the vent manufacturer’s instructions.

The water heater must be vented to the outdoors as described in these instructions. DO NOT connect this water heater to a Chimney. It must be vented separately from all other appliances.

All vent components (adapters, pipe, elbows, terminals, etc.) should be UL1738 Certified Stainless Steel Venting Material

(e.g.

The specified vent termination must be used. The termination should be a 90° elbow type with screen. (Refer to page 17)

Use a vent pipe with an

The use of a High Temperature Silicone (500°F) (260°C) may be required to seal vent connections. To prevent accidental gas exhaust leakage, apply a 1/4” (6 mm) wide bead approximately 1/4” (6 mm) from the end and another bead against the joint side of the stop bead.

Follow vent manufacturer’s installation instructions.

The unit can be vented either horizontally or vertically.

Vent pipe runs must be adequately supported along both horizontal and vertical runs.

The maximum recommended unsupported span should be no more than five (5) feet (1.5 m) Support isolation hanging bands should be used. DO NOT use wire. (See

NO!YES!

diagram below).

Notes on

If the water heater is being installed as a replacement for an existing water heater, a thorough inspection of the existing venting system must be performed prior to any installation work. Verify that the correct materials, vent lengths and terminal locations as detailed in this Use and Care manual have been met. Carefully inspect the entire venting system for any signs of cracks or fractures, particularly at the joints between elbows or other fittings and the straight runs of vent pipe. Check the system for signs of sagging or other stresses in the joints as a result of misalignment of any components in the system. If any of these conditions are found, they must be corrected in accordance with the venting instructions in this manual before completing the installation and putting the water heater into service.

Number of | Maximum |

90° elbows | Length of |

(bends) | Straight Pipe |

147’ 6”

(14.4 m)

242’ 6” (13 m)

337’ 6”

(11.4 m)

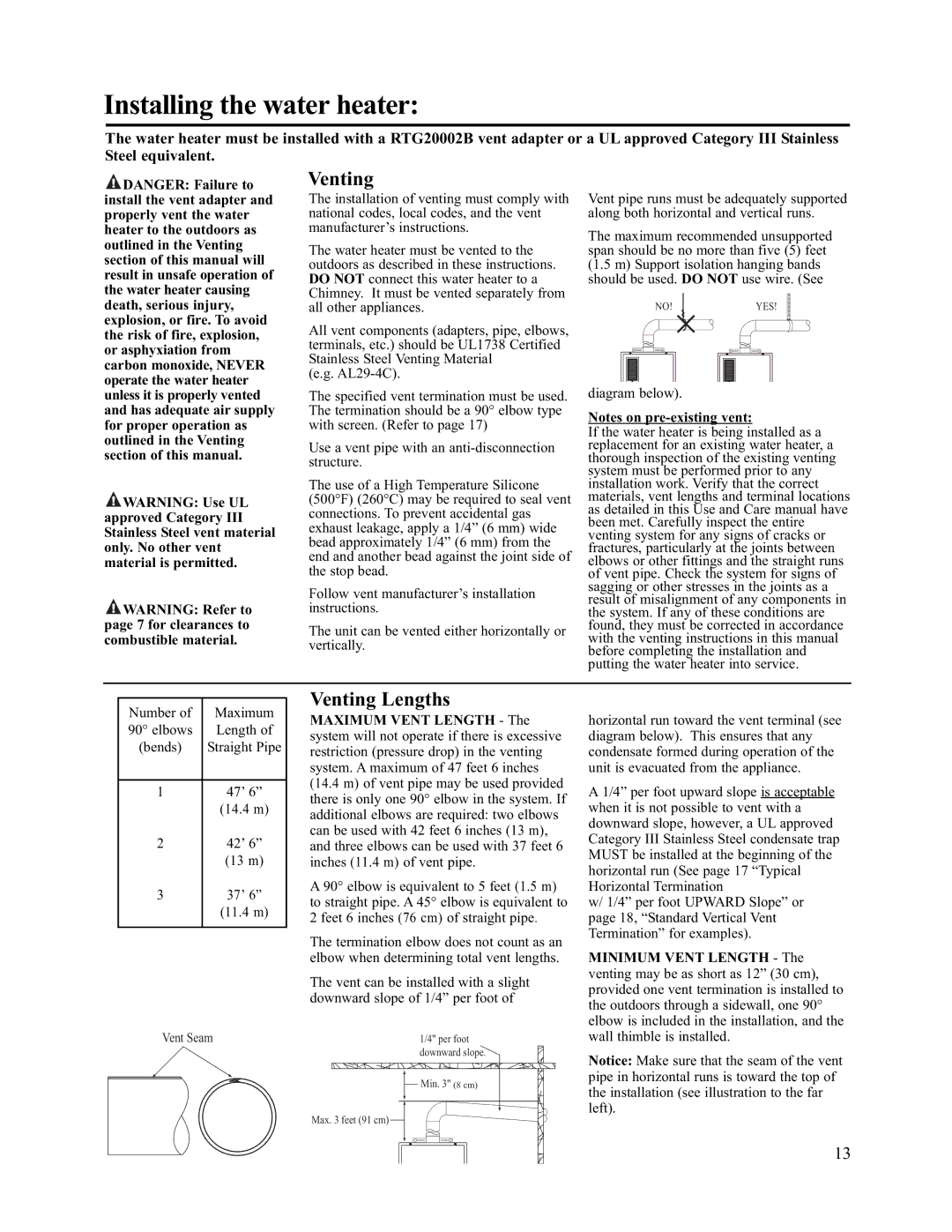

Vent Seam

Venting Lengths

MAXIMUM VENT LENGTH - The

system will not operate if there is excessive restriction (pressure drop) in the venting system. A maximum of 47 feet 6 inches (14.4 m) of vent pipe may be used provided there is only one 90° elbow in the system. If additional elbows are required: two elbows can be used with 42 feet 6 inches (13 m), and three elbows can be used with 37 feet 6 inches (11.4 m) of vent pipe.

A 90° elbow is equivalent to 5 feet (1.5 m) to straight pipe. A 45° elbow is equivalent to 2 feet 6 inches (76 cm) of straight pipe.

The termination elbow does not count as an elbow when determining total vent lengths.

The vent can be installed with a slight downward slope of 1/4” per foot of

1/4" per foot |

downward slope. |

Min. 3" (8 cm) |

Max. 3 feet (91 cm) |

horizontal run toward the vent terminal (see diagram below). This ensures that any condensate formed during operation of the unit is evacuated from the appliance.

A 1/4” per foot upward slope is acceptable when it is not possible to vent with a downward slope, however, a UL approved Category III Stainless Steel condensate trap MUST be installed at the beginning of the horizontal run (See page 17 “Typical Horizontal Termination

w/ 1/4” per foot UPWARD Slope” or page 18, “Standard Vertical Vent Termination” for examples).

MINIMUM VENT LENGTH - The

venting may be as short as 12” (30 cm), provided one vent termination is installed to the outdoors through a sidewall, one 90° elbow is included in the installation, and the wall thimble is installed.

Notice: Make sure that the seam of the vent pipe in horizontal runs is toward the top of the installation (see illustration to the far left).

13