MAINTENANCE

MAIN GEARBOX

1.Remove bearing (Ref. #8 Figure 8) from inside main housing. A special slide hammer puller (PROTO No. 4056) or equal may be required to remove bearing. Press in new bearing using driving tube or pipe with approximate same OD. as bearing. Seat outer race of bearing against shoulder in housing.

GEARBOX ASSEMBLY STEPS

Clean and scrape all gasket surfaces.

A.

1.Insert output shaft assembly into main housing and press into place. NOTE: Use pipe or tube with approximate same OD. as bearing and press into place by striking or pressing on tube.

2.Prelube lower bearing.

3.Place lower gasket in place and then carefully slide bearing retainer cap assembly down shaft. 4.Install bolts and lockwashers and torque to

B.

1.Assemble three shims onto input shaft housing. Insert input shaft assembly into main housing by installing shaft end into bearing in main housing. It may be necessary to rotate shaft to align gear teeth so that housing will install completely.

2. Install washers and bolts and torque to

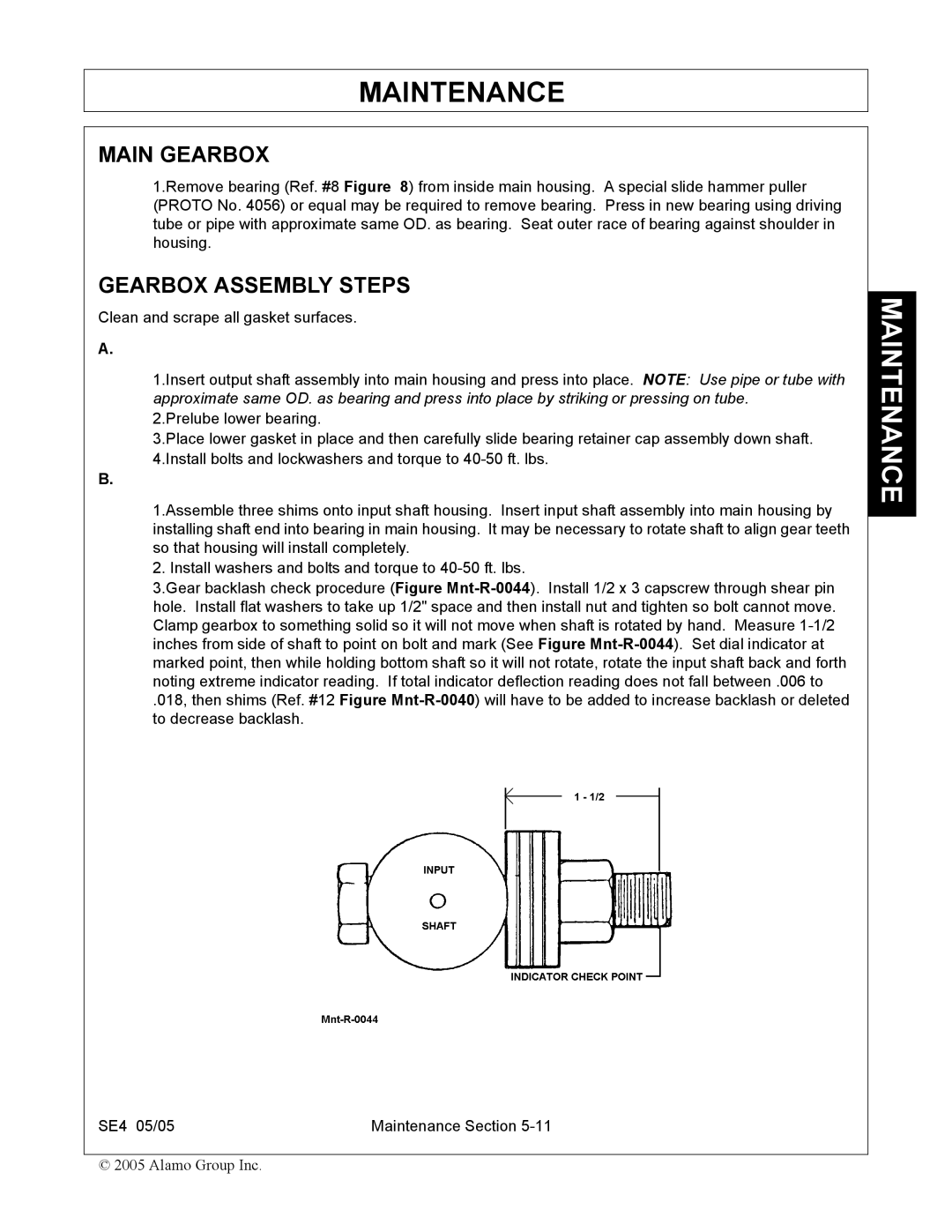

3.Gear backlash check procedure (Figure

.018, then shims (Ref. #12 Figure

SE4 05/05 | Maintenance Section |

© 2005 Alamo Group Inc.